Why Do Diesel Engines Need a Vacuum Pump?

In the world of automotive engineering, diesel engines operate differently compared to gasoline engines. One intriguing component that differentiates diesel engines is the vacuum pump. But why do diesel engines need a vacuum pump, and what role does it serve? This article will explore the purpose, functions, and mechanics behind vacuum pumps in diesel engines, offering a comprehensive guide to anyone curious about these essential automotive components.

Understanding Diesel Engines

What Makes Diesel Engines Different?

Unlike gasoline engines, diesel engines operate on a different combustion principle. Instead of using a spark plug to ignite an air-fuel mixture, diesel engines compress air until it reaches a temperature high enough to ignite the injected diesel fuel. This fundamental difference influences how auxiliary systems, like brakes and emissions, are managed.

Diesel engines do not produce a vacuum naturally like gasoline engines do. Gasoline engines create a vacuum during the intake stroke due to the throttle plate controlling airflow into the engine. In diesel engines, air intake is generally unrestricted, which means there is little to no vacuum generated. This creates a need for a separate mechanism to generate vacuum power for various functions.

- Throttle Plate: Gasoline engines rely on a throttle plate to regulate airflow, leading to vacuum generation.

- Diesel Mechanism: Diesel engines, lacking this throttle plate, require an external system—a vacuum pump.

A vacuum pump in a diesel engine provides the necessary negative pressure to operate key systems that are critical to the safety and functionality of the vehicle.

Primary Functions of a Vacuum Pump in Diesel Engines

1. Brake Booster Support

One of the primary functions of a vacuum pump in a diesel engine is to provide negative pressure to the brake booster. Diesel engines need this pump because they lack natural vacuum pressure for brake assist systems, unlike their gasoline counterparts.

- Brake Booster Operation: A brake booster uses vacuum pressure to reduce the effort needed to press the brake pedal. The vacuum pump ensures consistent vacuum levels to help drivers brake efficiently.

- Safety Aspect: Without a functioning vacuum pump, braking efficiency could significantly decrease, compromising safety.

The presence of a vacuum pump ensures that the brake booster functions properly, providing power assistance to the braking system for a smoother, easier, and more reliable driving experience.

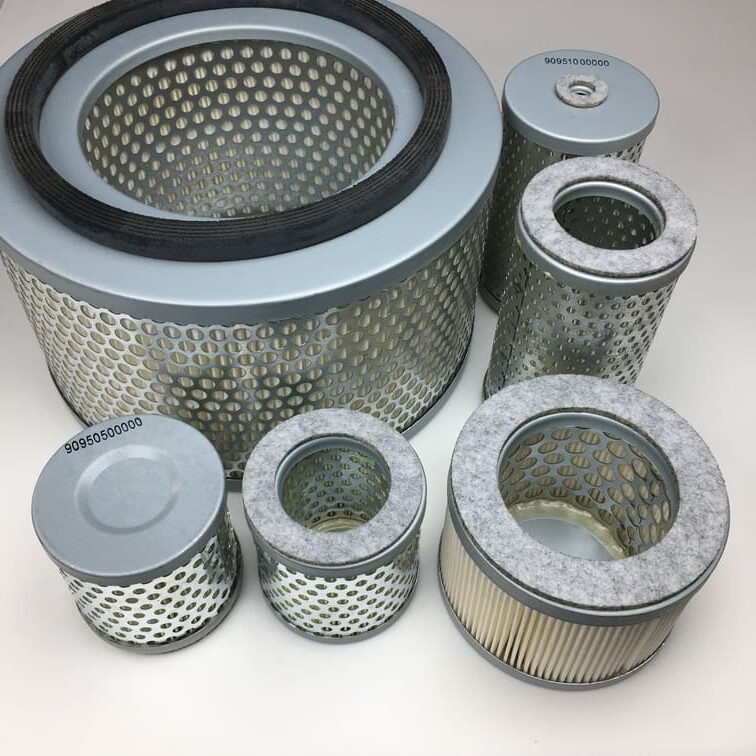

(Brake booster vacuum pump component from Becker)

(Brake booster vacuum pump component from Becker)

2. Emission Control Systems

Another critical function of a vacuum pump is to support emission control systems. Modern diesel engines are equipped with systems designed to reduce emissions and meet stringent environmental standards.

- EGR (Exhaust Gas Recirculation): The EGR system relies on vacuum to redirect a portion of the exhaust gases back into the engine cylinders, which helps to reduce nitrogen oxide emissions.

- Turbocharger Wastegate Control: Many turbocharged diesel engines use vacuum pumps to control the wastegate and adjust boost pressure for optimal performance.

These functions contribute to cleaner exhaust, improved fuel efficiency, and compliance with environmental standards, making the vacuum pump an essential part of the diesel engine’s emission control strategy.

Types of Vacuum Pumps Used in Diesel Engines

Mechanical vs. Electric Vacuum Pumps

Diesel engines can use either mechanical or electric vacuum pumps depending on the design of the vehicle and the required functionality.

| Type | Description | Pros | Cons |

|---|---|---|---|

| Mechanical | Driven by the engine via a belt or gear | Reliable at high RPMs | Inefficient at low RPMs |

| Electric | Operates independently of engine speed | Consistent performance | Requires electrical power |

Mechanical Vacuum Pumps are often driven by the camshaft or other engine components, making them effective while the engine is running at high speeds. However, their performance may vary with engine RPMs. On the other hand, electric vacuum pumps are more versatile as they can operate independently of the engine’s speed, providing a steady vacuum when needed.

Key Differences and Applications

- Heavy-Duty Diesel Engines: These typically use mechanical pumps as they can withstand high loads and are simpler to maintain.

- Modern Diesel Cars: Newer vehicles often use electric pumps due to their efficiency and the ability to operate without being tied to engine speed, making them ideal for city driving with frequent stops.

To explore various vacuum pump options, including different types of Becker Air Filters and pumps, visit our Vacuum Pump Spare Parts page.

How Vacuum Pumps Work in Diesel Engines

The Working Mechanism of a Vacuum Pump

A vacuum pump creates negative pressure by drawing in air and expelling it, reducing the pressure inside a connected chamber. The pump has inlet and outlet ports that allow air to move through the system.

- Rotary Vane Pumps: One of the most common types used in diesel engines is the rotary vane vacuum pump. It has vanes mounted on a rotor that creates a vacuum by trapping air and moving it through the pump body.

- Diaphragm Pumps: Another type is the diaphragm pump, which uses a diaphragm to create a vacuum. This type is less common in automotive applications due to its limited pressure capability.

Key Components of a Vacuum Pump

- Rotor and Vanes: The rotor spins inside the pump, and the vanes extend to create chambers of varying sizes, which helps in air displacement.

- Inlet and Outlet: Air enters through the inlet, and then the low-pressure air is expelled through the outlet.

- Drive Mechanism: The drive mechanism is either connected to the engine (mechanical) or powered electrically.

To learn more about specific types of vacuum pumps, including rotary vane vacuum pumps, you can visit our Becker Set of Vacuum Vanes product page.

(Becker rotary vane vacuum pump vanes)

(Becker rotary vane vacuum pump vanes)

Maintenance Tips for Diesel Vacuum Pumps

Routine Checks and Inspections

Regular maintenance of a vacuum pump is crucial to ensure optimal performance. This involves routine checks and inspections to identify potential issues before they escalate.

- Check for Leaks: Inspect all hoses and connections for signs of leaks. Even a small leak can significantly affect the system’s performance.

- Listen for Unusual Sounds: Unusual noises could indicate worn vanes or other internal damage.

- Replace Filters Regularly: Keep the air filters clean and replace them as necessary to prevent contamination of the vacuum system.

To find reliable replacement filters, consider checking out our Becker Air Filter replacements.

Common Issues with Vacuum Pumps

Vacuum pumps can encounter issues such as oil contamination, worn vanes, and leaks. Addressing these issues promptly ensures the longevity of the pump and maintains the engine’s overall performance.

- Oil Contamination: Since some vacuum pumps use oil for lubrication, it is essential to change the oil at recommended intervals to avoid contamination.

- Worn Vanes: Vanes wear out over time and must be replaced to maintain the pump’s effectiveness. Symptoms of worn vanes include decreased braking efficiency and increased braking effort.

Replacement and Repair

- Vane Replacement: If the vanes are worn, they need to be replaced. Replacement vanes are available in different sets, like the Becker Set of 7 Vanes which you can check out here.

- Professional Repair: While some minor maintenance tasks can be done by the vehicle owner, it’s often advisable to seek professional repair for more complex issues, such as internal damage or complete pump failure.

Safety and Efficiency of Vacuum Pumps in Diesel Engines

Enhancing Brake Performance

A well-maintained vacuum pump ensures consistent brake performance. By providing the necessary pressure to the brake booster, the vacuum pump allows for a safer and more comfortable driving experience, especially in situations requiring quick stops or emergency braking.

- Reduced Brake Effort: The power assistance provided by the brake booster reduces the amount of physical force the driver needs to apply to the brake pedal.

- Safety: With proper functioning, the vacuum pump ensures the reliability of the braking system, preventing brake fade and enhancing overall safety.

Contribution to Environmental Efficiency

Vacuum pumps are instrumental in reducing diesel emissions. By supporting components like the EGR valve, they help control the amount of exhaust gases that are recirculated, which directly impacts the engine’s efficiency and emission levels.

- Lower Emissions: Proper vacuum pump operation helps in maintaining low emission levels, keeping the vehicle compliant with environmental regulations.

- Fuel Efficiency: Through optimal performance of the EGR system, a well-functioning vacuum pump can also contribute to improved fuel efficiency.

Frequently Asked Questions

1. What happens if a vacuum pump fails in a diesel engine?

If a vacuum pump fails, several systems in the vehicle may stop functioning properly, including the brake booster. This could make braking more difficult and affect overall safety.

2. How can I tell if my vacuum pump is malfunctioning?

Signs of a failing vacuum pump include increased braking effort, hissing noises, and reduced engine performance due to the failure of the emission control systems.

3. Can I replace a vacuum pump myself?

While it is possible to replace a vacuum pump yourself, it is often recommended to have it done by a professional, especially if you’re not familiar with automotive systems.

4. Are all vacuum pumps the same for diesel engines?

Not all vacuum pumps are the same for diesel engines. Different engine models may require different specifications, types, or designs of vacuum pumps to ensure optimal performance and compatibility.

Conclusion

In conclusion, vacuum pumps play a vital role in diesel engine performance, particularly in terms of brake assistance and emission control. Understanding the mechanics and importance of these pumps helps ensure that the engine remains reliable and efficient. Replacing or maintaining the vacuum pump is a key aspect of diesel engine care that should not be overlooked. Regular inspections and proper maintenance can lead to safer driving, improved fuel efficiency, and compliance with environmental standards. Keeping your vacuum pump in excellent condition will ultimately enhance both your driving experience and vehicle safety.

For any vacuum pump needs or to find suitable replacement parts, explore our extensive range of Vacuum Pump Spare Parts.