Frequently Asked Question

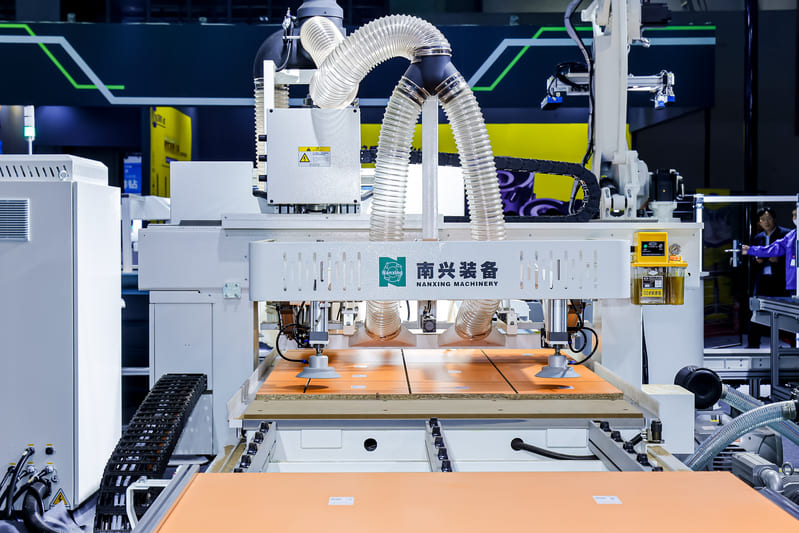

1. Q: How long does it take for my order to be delivered?

A: We pride ourselves on fast delivery. All orders are processed and shipped within 3 business days, ensuring minimal downtime for your equipment.

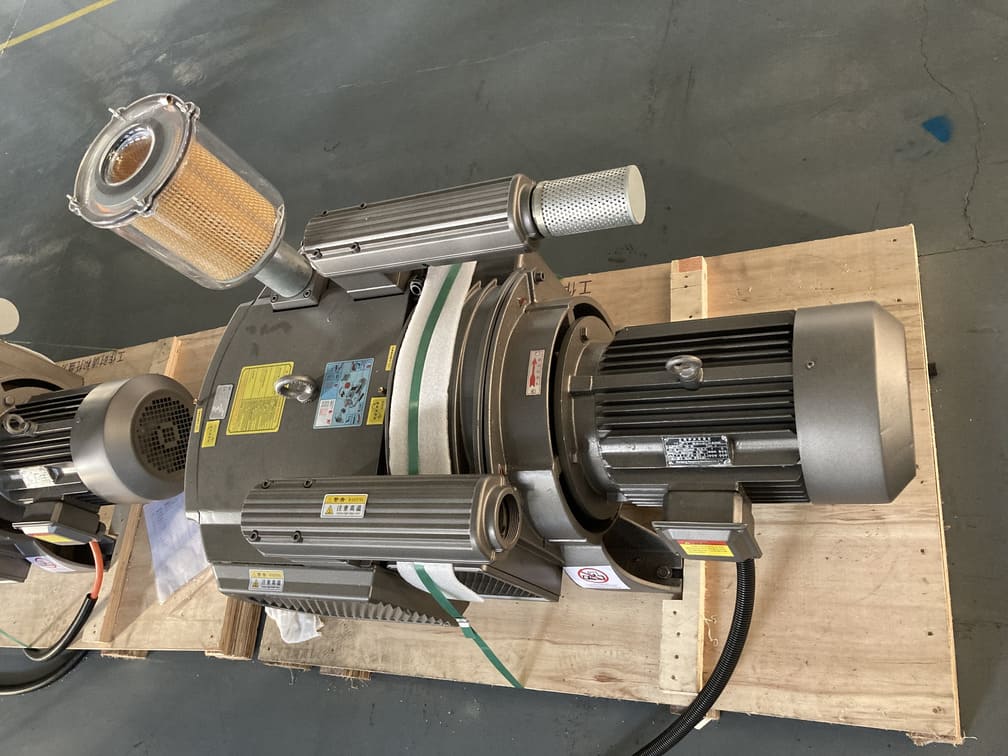

2. Q: What kind of warranty do you offer on carbon vanes?

A: Yes, all of our carbon vanes meet OEM quality standards, ensuring optimal performance and longevity for your vacuum pumps.

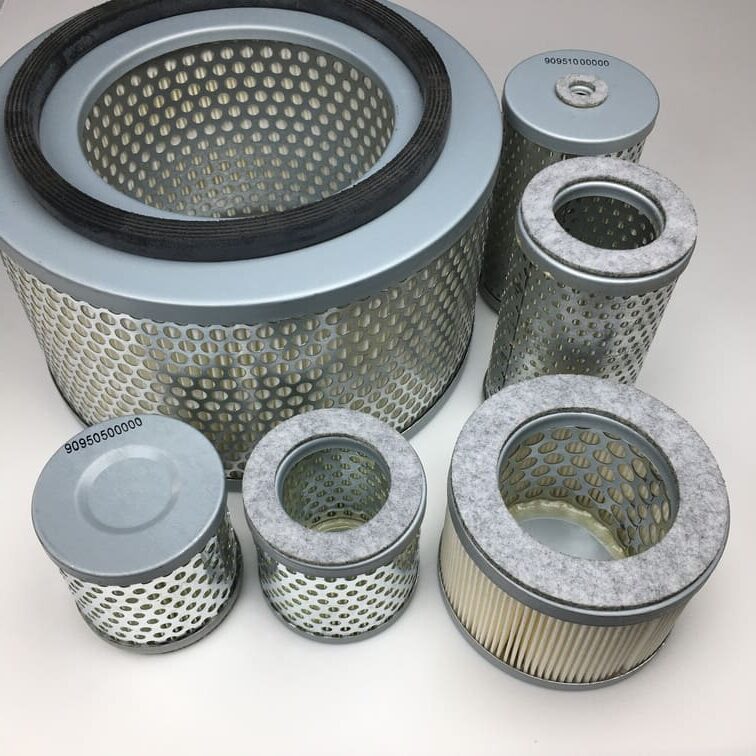

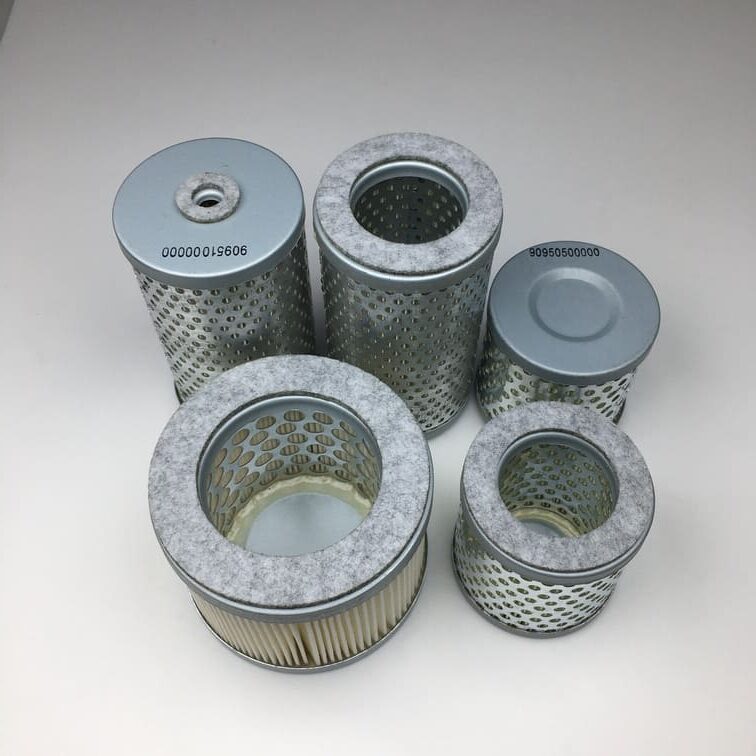

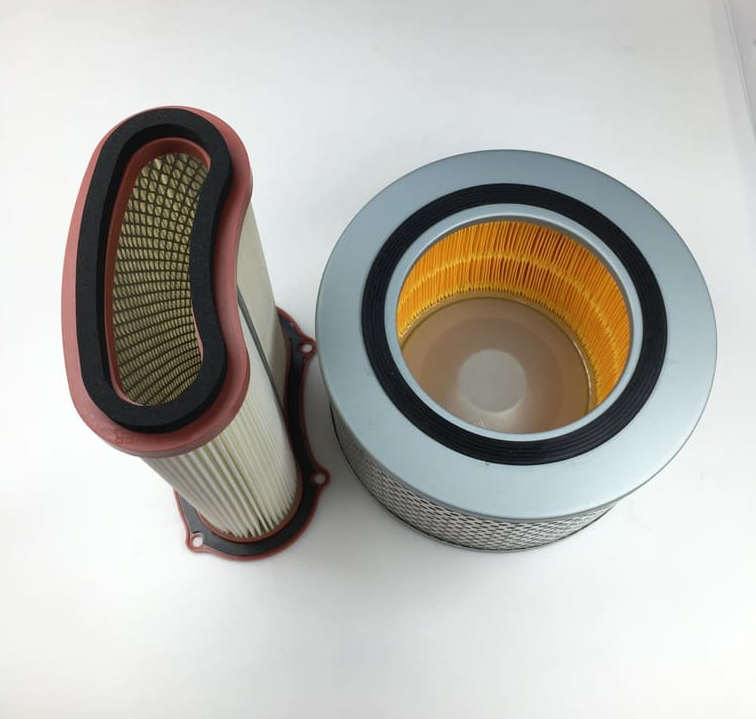

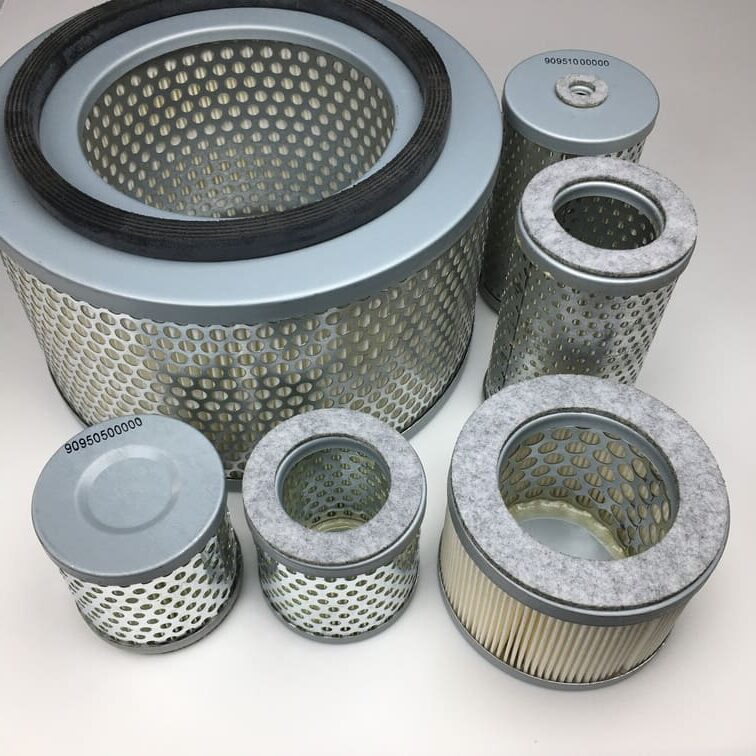

3. Q: How often should the filter be replaced?

A: There is no exact replacement time for the filter. Above all, it depends on the working conditions.