When it comes to vacuum pumps, Why choose carbon vanes instead of plastic vanes or metal vanes in most vacuum pumps? This is a pressing question for professionals seeking durability, efficiency, and sustainability in today’s industrial landscape. Below, we will explore why carbon vanes are so appealing, and how they compare with other materials often used in vacuum pump systems. Our goal is to present the information in a clear, engaging manner that conveys both technical insight and practical guidance.

1. Understanding Carbon Vanes

Carbon vanes are specialized components produced from carbon-graphite materials. They are commonly found in rotary vane pumps, vacuum pumps, and rotary vane compressors. Unlike plastic or metal vanes, carbon vanes present advantages such as self-lubrication, enhanced durability, and improved energy efficiency. These attributes enable carbon vanes to keep pumps running smoothly even under harsh working conditions.

Key Benefits at a Glance

- Self-lubricating surface that reduces friction and wear

- Prolonged lifespan under high pressures or temperatures

- Reduced maintenance demands thanks to resilient carbon-graphite composition

- Minimal contamination of processed materials

Quote: “Carbon vane technology is shifting industrial practices by promoting better operation with less waste and maintenance.”

2. How Carbon Vanes Compare to Plastic Vanes

Plastic vanes—commonly made from materials like nylon or polyester—tend to be lightweight and relatively cost-effective. However, they might not withstand the same rigorous conditions where carbon vanes excel.

Table: Comparing Carbon Vanes and Plastic Vanes

| Feature | Carbon Vanes | Plastic Vanes |

|---|---|---|

| Durability | Very high due to solid carbon | Moderate, can deform or crack under high stress |

| Self-lubrication | Yes | Limited |

| Heat Tolerance | Excellent, high stability | Lower threshold for damage |

| Potential Maintenance | Lower frequency | Higher frequency if under extreme loads |

Despite the advantages of plastic in simpler applications, it generally lacks the mechanical robustness that carbon offers in intense or sustained tasks. Plastic’s performance can diminish in high-temperature environments or when faced with heavy friction.

3. Evaluating Metal Vanes vs. Carbon Vanes

Metal vanes—whether made of stainless steel, aluminum, or another alloy—are prized for their strength and corrosion resistance. Nonetheless, carbon vanes frequently surpass them in several ways.

Strength and Wear

- Carbon Vane Strength: Carbon’s hardness resists abrasion, prolonging vane life even under tough conditions.

- Metal Vane Strength: Metals, while structurally strong, are heavier and can be prone to surface wear over time.

Weight and Efficiency

- Carbon: Low weight leads to less energy consumption, allowing pumps to operate more efficiently.

- Metal: Heavier weight can influence overall power draw, possibly driving up system costs.

Insight: “While stainless steel vanes offer noteworthy durability, carbon-graphite often proves more cost-effective long-term by reducing downtime and maintenance needs.”

4. Top Advantages of Carbon Vanes in Vacuum Pump Applications

Many vacuum pump designs—particularly rotary vane vacuum pumps—rely on carbon vanes to provide consistent and efficient operations. Let’s examine some of the major advantages:

- Self-Lubrication

Carbon vanes exhibit self-lubricating characteristics, meaning they usually operate smoothly without requiring oil-based lubricants. As a result, wear on the pump’s internal surfaces is reduced, and contamination risk to the pumped fluid or environment is minimized. - Extended Service Life

Carbon vanes handle high pressure and high temperature extremes with minimal mechanical breakdown. This resilience translates to fewer replacement intervals, saving both time and money. - Environmental Sustainability

Thanks to their reliable performance and low friction, carbon vanes help lower energy consumption. Less downtime also implies a reduced carbon footprint since fewer replacements and repairs translate to less resource use overall.

5. Core Industries That Rely on Carbon Vanes

Carbon vanes appear in a wide variety of industries, from food processing to chemical handling. Below are some examples of key sectors that benefit from carbon vane reliability:

- Automotive and Aerospace: Carbon vanes can operate under extreme heat and speed, enabling pumps to sustain performance without excessive wear.

- Chemical and Food Processing: They handle aggressive chemicals or delicate food products with minimal risk of contamination.

- Printing and Spraying: Where consistent flow of liquids is crucial for accuracy, self-lubricating carbon vanes maintain smooth operations.

List: Why Carbon Vanes Excel Here

- Compatible with harsh fluids

- Resist high mechanical loads

- Extended run times with minimal maintenance

6. FAQs: Addressing Common Carbon Vane Questions

1. How do carbon vanes self-lubricate?

Carbon’s graphite structure contains microscopic lubrication properties, which help reduce friction within the pump chamber. This design allows carbon vanes to work reliably without additional lubricants.

2. Are carbon vanes costlier than plastic or metal vanes?

Initial costs might be higher. However, carbon vanes last longer and require fewer replacements, often leading to lower overall expenses.

3. Do carbon vanes handle chemicals well?

Yes. Carbon vanes have excellent chemical compatibility, making them ideal for food processing, chemical, or pharmaceutical uses.

4. Can I install carbon vanes in my existing vacuum pump?

In many cases, yes. Retrofitting carbon vanes can be straightforward, though you should always review manufacturers’ guidelines or consult a trusted supplier to ensure compatibility.

5. Do carbon vanes resist high temperatures and pressure?

Absolutely. Carbon’s thermal stability and inherent strength reduce damage under high-heat and high-pressure environments, prolonging the vane’s life.

7. Carbon Vanes in Specialized Vacuum Pump Parts

For those seeking high-grade vacuum pump parts, we recommend exploring reliable carbon vanes from specialized suppliers. Below are a few relevant resources featuring vacuumpumppart.com internal links with semantically relevant anchor text:

- 90138800005 | WN 124-220 Original Becker Set of 5 Vanes

- 90137301010 | WN 124-205 Original Becker Set of 10 Vanes

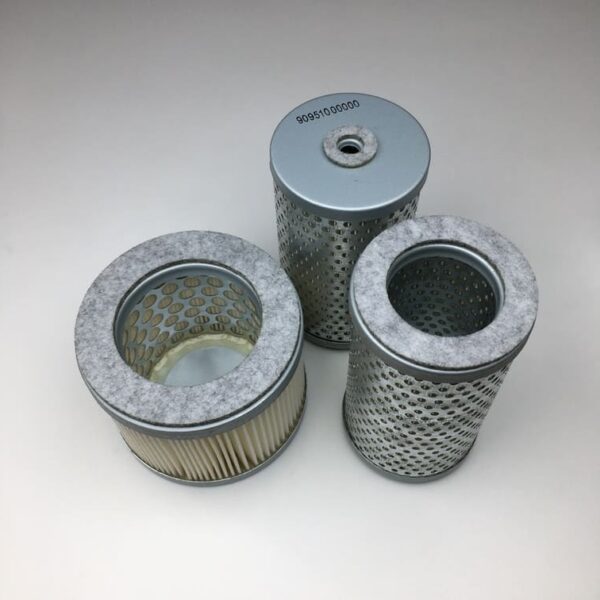

- Becker Air Filter replaces Becker 909540

When searching for carbon vanes or complementary vacuum pump parts, verifying product compatibility and exact dimensions ensures a seamless integration into your existing system.

8. Practical Comparisons: Carbon vs. Plastic vs. Metal

While carbon vanes often outperform plastic or metal in demanding vacuum pump conditions, it’s important to identify any potential exceptions. Situations requiring only low-intensity operation might suffice with plastic, whereas extremely specialized settings might rely on certain metal alloys. However, for a broad range of industrial uses, carbon remains the prime choice, merging strong mechanical features with cost-saving durability.

Table: Quick Overview of Material Attributes

| Attribute | Carbon Vane | Plastic Vane | Metal Vane |

|---|---|---|---|

| Wear Resistance | Excellent | Moderate to Good | Good but depends on alloy |

| Friction | Very Low (self-lubricating) | Higher, needs lubrication | Medium, possible galling |

| Thermal Stability | High | Limited in extremes | Depends on metal type |

| Environmental | Often more eco-friendly | Might degrade or warp | Can corrode or oxidize |

Note: Real-world applications highlight how carbon vanes frequently outlive and outperform their plastic or metal counterparts in vacuum pump roles.

Conclusion

Why choose carbon vanes instead of plastic vanes or metal vanes in most vacuum pumps? The answer lies in exceptional durability, self-lubrication, and high efficiency delivered by carbon’s unique properties. By adopting carbon vanes, operators gain not only reliable performance but also minimized replacement intervals—translating into less downtime and lower overall costs.

Key Takeaways

- Carbon vanes have solid carbon-graphite composition for impressive wear resistance.

- Self-lubrication streamlines operations and curbs contamination.

- Comparatively lightweight materials boost energy efficiency in vacuum pumps.

- Industries ranging from chemical to food processing rely on carbon vanes to manage high-stress or high-heat conditions.

- Plastic or metal alternatives may cost less initially but often lack the longevity that carbon provides.

We trust this overview clarifies the value that carbon vanes bring to vacuum pumps. If you need well-built, reliable solutions or want to explore carbon vane upgrades for existing systems, feel free to reach out—we’re here to help you achieve optimal performance in your applications.