Vacuum pumps are essential tools used in various industries, from automotive to industrial applications, and they are particularly crucial for maintaining effective system pressure. However, one common issue that may arise during the use of a vacuum pump is oil getting sucked into the hose. This phenomenon can lead to reduced pump efficiency, contamination of the vacuum system, and even equipment damage. In this article, we will explore why this happens, how to prevent it, and practical maintenance tips to ensure your vacuum pump operates effectively.

Understanding How Vacuum Pumps Work

What is a Vacuum Pump?

A vacuum pump is a mechanical device that removes gas molecules from a sealed volume, thereby creating a vacuum. It is a crucial part of systems where maintaining low pressure is essential, such as in refrigeration, HVAC, automotive brake boosters, and laboratory applications.

The vacuum pump has a few key components:

- Pump Body: Houses the internal parts.

- Oil Reservoir: In oil-lubricated vacuum pumps, oil is used to seal and lubricate the moving components, increasing the vacuum level achievable.

- Hoses: Connect the vacuum pump to the system being evacuated.

The vacuum pump’s efficiency largely depends on its internal components being well-lubricated and free from contamination. Oil-lubricated rotary vane pumps, for instance, rely on oil to ensure the vanes slide smoothly and create a good seal against the pump wall.

Why Is Oil Needed in Vacuum Pumps?

In oil-lubricated vacuum pumps, oil plays an essential role:

- Lubrication: Oil reduces friction between moving parts, which helps to extend the lifespan of the pump.

- Sealing: The oil creates a seal to minimize leaks, helping the pump to maintain a high vacuum.

- Cooling: Oil helps dissipate heat generated by the mechanical parts during operation.

Reasons for Oil Sucking Into the Hose

One of the common issues that users experience is oil being sucked into the vacuum hose. This typically happens due to a combination of factors, which can include improper operation, mechanical failure, or maintenance neglect. Let’s dive into the most common causes:

1. Incorrect Oil Level

Maintaining the correct oil level in a vacuum pump is crucial. If the oil level is too high, it may overflow into the pump’s suction area, eventually leading to oil being sucked into the hose.

- High Oil Level: If too much oil is added to the pump, it can cause splashing, where oil is drawn into the vacuum chamber and ultimately gets sucked into the hose.

- Low Oil Level: An insufficient oil level can also cause problems, such as inadequate lubrication, which may lead to damage or leaks, causing oil to be drawn into areas where it shouldn’t be.

Tip: Always follow the manufacturer’s guidelines on maintaining proper oil levels. Using an oil gauge can be an excellent way to ensure the oil level is optimal.

2. Backstreaming

Backstreaming occurs when oil vapor from the pump gets into the vacuum system. This usually happens in rotary vane pumps when the pressure falls below the pump’s designed operating range, causing oil vapor to move backward through the system and into the hose.

- Inadequate Traps: If your system does not include appropriate traps or filters, oil vapor can easily travel from the pump through the hose, contaminating your vacuum environment.

- Sudden Shutdown: When a vacuum pump is shut down abruptly without venting, it can lead to a pressure equalization issue, which may force oil to be sucked into the hose.

Prevention: Installing an oil mist eliminator or an anti-suckback valve can help mitigate backstreaming issues.

3. Seal Failure

Seal failures in vacuum pumps are another common cause of oil sucking into the hose. Seals ensure that different sections of the pump are effectively separated to maintain proper function.

- Worn Seals: Over time, seals can wear out due to high temperatures, contamination, or simple mechanical wear and tear. Worn seals may allow oil to leak into areas where it can be sucked into the hose.

- Damaged Vanes: In rotary vane pumps, vanes that have sustained damage may create improper gaps or even break, leading to improper vacuum conditions and oil being pulled into the hose.

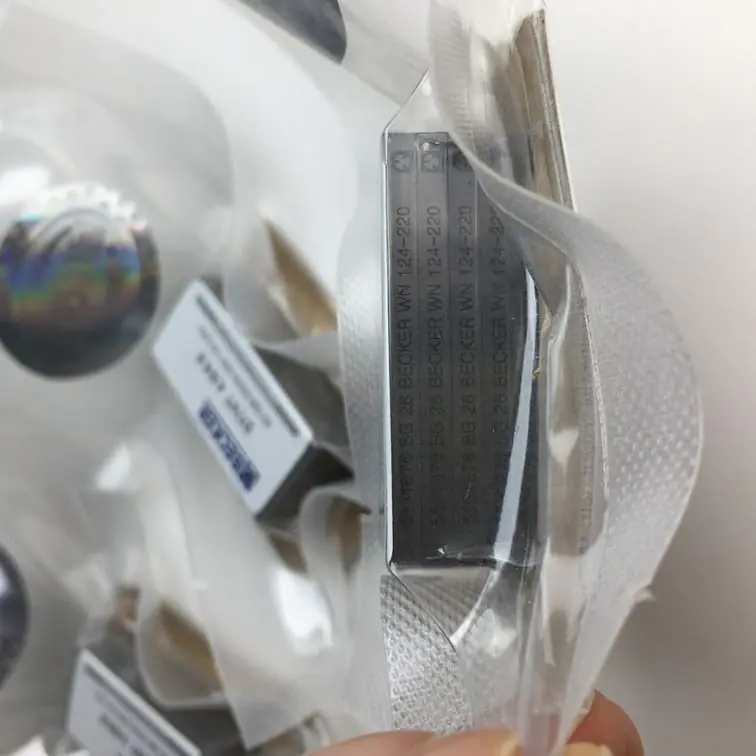

Maintenance Tip: Regularly check and replace worn-out seals and vanes. Consider using high-quality vanes like the 90138800005 | WN 124-220 Original Becker Set of 5 Vanes.

4. Operating Under Incorrect Pressure

Vacuum pumps are designed to work under specific pressure ranges. Operating outside these parameters can create an imbalance, which might cause oil to be sucked into the hose.

- Too Low a Pressure: Operating the pump at too low a pressure can increase the likelihood of oil backstreaming into the hose.

- Fluctuating Pressure: Significant pressure fluctuations may also cause oil to move erratically inside the pump, increasing the risk of oil contamination.

Solution: Maintain stable operating conditions and ensure that the pump is operating within its recommended pressure range. Installing pressure control mechanisms can help stabilize the system.

5. Improper Hose Positioning

The position of the hose can also be a contributing factor to oil being sucked in. If the vacuum hose is positioned incorrectly, gravity or suction force may cause oil to flow into the hose.

- Incorrect Angle: Hoses that are positioned below the level of the pump oil reservoir can allow oil to easily flow towards the vacuum side during operation or shutdown.

- Blocked or Restricted Hoses: Hoses that have blockages may create extra pressure that could lead to oil being forced up into the vacuum line.

Tip: Always place the vacuum hose above the oil reservoir level and ensure that it has no restrictions to prevent the backflow of oil.

Preventive Measures to Avoid Oil Sucking into the Hose

Use an Anti-Suckback Valve

An anti-suckback valve is a crucial component that prevents oil from flowing backward into the vacuum system when the pump is stopped. This valve blocks the passage of oil into the vacuum hose when the pump is turned off.

- Automatic Valves: Many modern vacuum pumps are fitted with anti-suckback valves that activate automatically when the pump is shut down.

- Retrofit Option: For older pumps, consider retrofitting an anti-suckback valve to help prevent oil contamination in the vacuum line.

Proper Oil Selection

Choosing the right oil is critical for vacuum pump performance and helps minimize the risk of oil contamination in the system.

- Low Vapor Pressure Oil: Use oil with low vapor pressure to reduce the chance of backstreaming. Products like triple-distilled pump oil are formulated to minimize vaporization.

- Change Oil Regularly: Changing the oil at recommended intervals ensures that contaminants are removed and the pump continues to function efficiently.

Consider using high-quality vacuum oils available from reputable suppliers such as Vacuum Pump Spare Parts for dependable performance.

Ensure Regular Maintenance

Routine maintenance is key to preventing oil-related issues in vacuum pumps. Maintenance tasks include:

- Checking Seals and Valves: Regularly inspect seals and replace any that are worn or damaged.

- Oil Level Monitoring: Always keep the oil level within the manufacturer’s specifications. Adding or draining oil should be done while the pump is off and at ambient temperature.

- Cleaning Hoses: Clean or replace hoses periodically to prevent any build-up that may cause blockages or unwanted pressure.

FAQs

1. What causes oil to get sucked into the vacuum hose of a pump?

Oil gets sucked into the vacuum hose due to issues like incorrect oil levels, seal failures, backstreaming, improper hose positioning, or operating under incorrect pressure. Maintaining proper oil levels and using an anti-suckback valve can help prevent this issue.

2. How can I prevent oil from being sucked into my vacuum pump hose?

To prevent oil from being sucked into your vacuum pump hose, use an anti-suckback valve, ensure proper oil levels, and keep hoses positioned above the oil reservoir level. Regular maintenance is also crucial.

3. Why is the oil level important in a vacuum pump?

Maintaining the proper oil level is important because it ensures adequate lubrication, proper sealing, and prevents overflow, which can lead to oil contamination in the vacuum system.

4. What is backstreaming in vacuum pumps?

Backstreaming occurs when oil vapor moves from the pump back into the vacuum system. This can contaminate the vacuum chamber and hoses, often happening when the pump operates below its ideal pressure range.

5. Should I replace my vacuum pump oil frequently?

Yes, vacuum pump oil should be replaced at regular intervals as specified by the manufacturer. Fresh oil ensures optimal performance and reduces the risk of contamination.

Conclusion

Oil being sucked into the vacuum hose is a common issue that can significantly impact the efficiency of a vacuum pump system. This problem typically results from improper maintenance, incorrect operating conditions, or mechanical issues such as worn seals and improper oil levels. By understanding the potential causes and adopting preventive measures such as using an anti-suckback valve, maintaining correct oil levels, and regularly inspecting seals, you can effectively prevent oil from contaminating your vacuum system.

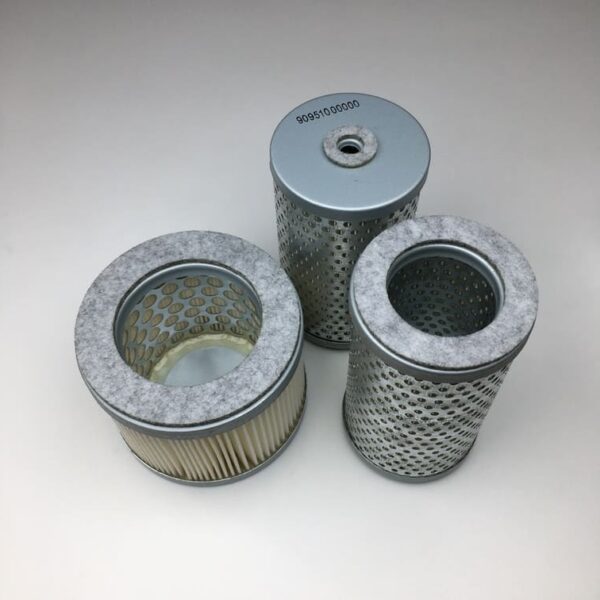

For high-quality vacuum pump parts and maintenance tools, explore products like Becker Air Filter replaces Becker 909540 to ensure your vacuum system continues to function efficiently and reliably.

Maintaining your vacuum pump properly will ensure optimal performance and help avoid costly repairs, making sure that your vacuum systems continue to function at their best.