Which Vacuum Pump is Best: A Comprehensive Guide

When it comes to choosing the best vacuum pump, the options can be overwhelming. Whether you need one for your industrial needs, automotive repairs, or scientific purposes, selecting the right pump makes all the difference in efficiency, cost-effectiveness, and application. In this article, we will explore the most common types of vacuum pumps, their applications, and how to determine the best fit for your specific needs.

What is a Vacuum Pump and Why Do You Need One?

A vacuum pump is a device that removes air and gases from a sealed system, creating a vacuum. The pump’s primary function is to reduce the pressure inside the chamber or system to an absolute minimum, which is essential in many applications, including manufacturing, automotive, and even healthcare.

Common Applications of a Vacuum Pump

- Automotive Uses: Vacuum pumps are crucial for brake systems, creating the necessary pressure for brake boosters.

- HVAC and Refrigeration: They are often used to evacuate air from systems to ensure proper refrigerant filling.

- Laboratory and Research: Vacuum pumps create controlled environments for conducting experiments in a low-pressure environment.

- Manufacturing and Packaging: They are used for vacuum forming, molding, and packaging processes to ensure quality and preserve items longer.

If you’re looking for reliable parts to maintain your pump, check out the Becker Air Filter replacements to ensure longevity.

Types of Vacuum Pumps

1. Rotary Vane Vacuum Pumps

Rotary vane pumps are some of the most common and versatile pumps available today. They use rotating vanes to trap air and force it out of the system, making them ideal for both low- and medium-vacuum applications. They are often employed in automotive and HVAC tasks due to their reliability and efficient performance.

Pros of Rotary Vane Pumps

- Cost-Effective: They are usually less expensive than other types of pumps.

- Efficient: Known for maintaining a steady vacuum pressure.

- Durable: Designed for long-term use when properly maintained.

Becker Air Filter replacements for rotary vane pumps help ensure optimal operation.

Cons of Rotary Vane Pumps

- Oil Maintenance: They need frequent oil changes to maintain efficiency.

- Heat Generation: These pumps can generate significant heat during prolonged operation, making cooling an essential consideration.

2. Dry Vacuum Pumps

Dry vacuum pumps operate without using any oil or lubrication, making them highly desirable in applications where contamination could be an issue. They are often used in pharmaceutical and food packaging industries where product contamination needs to be minimized.

Pros of Dry Vacuum Pumps

- Contamination-Free: No oil or lubricant means no risk of contaminating sensitive processes.

- Low Maintenance: Requires less frequent maintenance as there is no oil to replace.

- Eco-Friendly: With no need for oil disposal, they are an environmentally friendly choice.

Cons of Dry Vacuum Pumps

- Cost: Generally more expensive upfront compared to other types.

- Noise: They can be noisier due to the absence of lubrication, which also serves as a sound dampener.

For more specialized applications, browse Rietschle replacement parts for your dry vacuum pump.

| Pump Type | Application | Maintenance Requirement |

|---|---|---|

| Rotary Vane | HVAC, Automotive | Frequent oil changes |

| Dry Vacuum | Food, Pharmaceuticals | Low, no oil changes |

3. Diaphragm Vacuum Pumps

Diaphragm pumps utilize a flexible diaphragm to move air in and out of a chamber, generating a vacuum. These pumps are typically used in laboratories where small volumes of gas need to be pumped out of a system, such as gas chromatography or aspiration applications.

Pros of Diaphragm Pumps

- Chemical Resistance: These pumps are often made of materials that resist chemical corrosion, making them ideal for laboratory use.

- Low Noise Levels: They are generally quiet, providing a suitable option for indoor environments.

Cons of Diaphragm Pumps

- Limited Capacity: They are not suitable for creating high vacuums and work best with smaller systems.

- Speed: They may take longer to evacuate air compared to rotary vane pumps.

Factors to Consider When Choosing a Vacuum Pump

1. Application Needs

The intended use of your vacuum pump will significantly dictate which type is best for you. If you need a pump for your automotive shop, a rotary vane pump might be ideal. For chemical labs, a diaphragm pump would be a better option due to its chemical resistance.

2. Maintenance Requirements

Different types of pumps have varying maintenance requirements. If you want a low-maintenance option, a dry vacuum pump might be ideal. However, if the initial cost is an issue, you may opt for a rotary vane pump, understanding that it will require regular oil changes.

Tip: Always consider the maintenance cost as part of your budget for buying a vacuum pump. Overlooking this could lead to unexpected expenses down the line.

3. Budget Considerations

Cost is a significant factor, and not just the upfront cost. Dry vacuum pumps, for instance, have higher initial costs but may save you on maintenance expenses over time. On the other hand, rotary vane pumps are budget-friendly upfront but require consistent maintenance.

4. Environmental Concerns

Dry vacuum pumps are often considered more eco-friendly because they do not use oil, reducing both emissions and waste disposal needs. If your work environment has strict environmental regulations, you might want to choose a pump accordingly.

For reliable filters to support any of these systems, check out the Becker Air Filter 84040110, which works seamlessly with many vacuum pump systems.

How to Maintain Your Vacuum Pump Effectively

1. Regular Oil Changes

For oil-sealed pumps like rotary vane pumps, regularly changing the oil is crucial. Contaminated oil can significantly reduce the pump’s efficiency and may lead to premature wear and tear. Use high-quality vacuum pump oil for the best results.

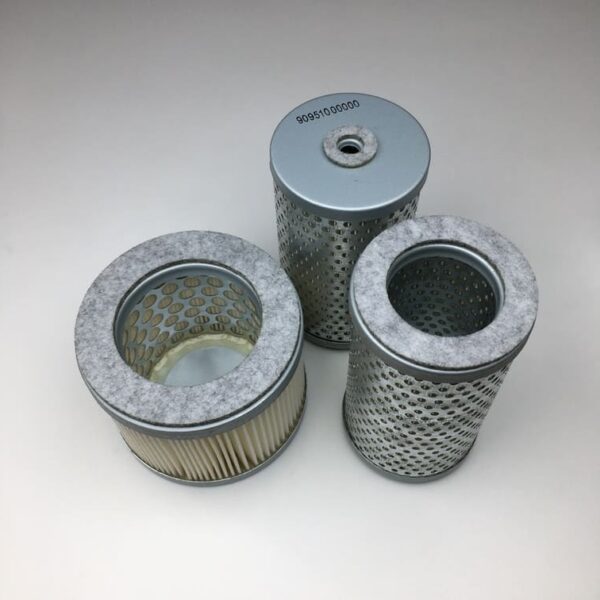

2. Inspect and Replace Filters

Dirty filters can decrease the efficiency of the pump, causing it to work harder and reducing its lifespan. Make sure to replace filters regularly with high-quality options, such as the Mann-Filter replacements to maintain optimal performance.

High-quality filters ensure optimal pump performance.

3. Check for Leaks

Leaks in the system can prevent the pump from achieving the required vacuum pressure. Inspect the pump, hoses, and connections frequently for any sign of leakage, and replace or repair as necessary.

4. Monitor Performance

Vacuum pumps should be monitored to ensure that they are performing correctly. This includes checking the pressure levels, noise, and temperature. Any anomalies could indicate a problem that requires immediate attention.

Pros and Cons of Different Vacuum Pump Types: Summary

| Pump Type | Pros | Cons |

|---|---|---|

| Rotary Vane | Cost-effective, Durable | Oil maintenance, Heat generation |

| Dry Vacuum | Contamination-free, Low maintenance | Expensive, Noisy |

| Diaphragm | Chemical-resistant, Quiet | Limited capacity, Slower |

FAQs About Choosing the Best Vacuum Pump

1. What is the best vacuum pump for an automotive shop?

For automotive uses, such as brake systems or AC repairs, rotary vane vacuum pumps are usually the best due to their efficiency and reliability.

2. Can I use a dry vacuum pump for all applications?

No, dry vacuum pumps are ideal for contamination-free environments but may not generate high levels of vacuum needed in certain industrial processes.

3. How often should I change the oil in a rotary vane vacuum pump?

The oil should be changed after every major use or at least every 500-1000 hours of operation. Regular checks are essential to ensure oil cleanliness.

4. Which vacuum pump type is the most energy-efficient?

Generally, diaphragm pumps are more energy-efficient due to their smaller capacity and specific application usage, but it depends on the scale and purpose of the application.

5. Can a vacuum pump be used for both air and liquids?

Yes, some pumps, like diaphragm pumps, can handle both air and certain types of liquids. However, be sure to check the manufacturer’s recommendations.

Conclusion

Choosing the best vacuum pump involves understanding your unique requirements, budget, and the specific application of the pump. Rotary vane, dry, and diaphragm pumps all have their unique strengths, and your choice should be based on the intended usage and required features.

Ensure regular maintenance, such as oil changes, filter replacements, and monitoring for leaks, to keep your vacuum pump in optimal condition. A well-maintained vacuum pump can enhance efficiency, reduce costs, and prolong the life of your equipment, saving you money in the long run.

For all your vacuum pump needs, from filters to replacement parts, visit Vacuum Pump Parts for requirements of high quality vacuum pump parts.