What Oil is Used in a Vacuum Pump?

Selecting the right oil for a vacuum pump is a crucial decision that directly impacts the pump’s efficiency, longevity, and overall performance. Vacuum pump oil acts as a lubricant, a sealant, and a heat transfer medium. However, there are many types of oils, each designed to work under different conditions and in different types of pumps. In this article, we will discuss the different types of vacuum pump oils, what to consider when choosing the right oil, and how to ensure your vacuum pump continues to operate effectively.

Understanding the Role of Vacuum Pump Oil

Vacuum pump oil is specially formulated to serve a few distinct purposes in a vacuum pump. Unlike conventional oils, vacuum pump oil is designed to reduce vapor pressure, maximize thermal stability, and provide lubrication under vacuum conditions. Its main functions are:

- Lubrication: Reduces friction between moving parts in the vacuum pump.

- Sealing: Helps maintain a vacuum by sealing the internal components of the pump.

- Cooling: Helps dissipate heat generated during the pump operation.

Without the right oil, a vacuum pump can experience rapid wear, inefficient operation, and even complete breakdown. Thus, it is essential to choose the correct type of oil based on the specific requirements of your pump.

Internal Link: To keep your vacuum pump running smoothly, be sure to check out our Vacuum Pump Spare Parts Guide.

Types of Vacuum Pump Oil

There are a few main types of vacuum pump oils, each with unique properties that make them suitable for different applications. Let’s take a closer look:

1. Mineral Oil

Mineral oil is one of the most commonly used vacuum pump oils, especially in rotary vane pumps. It is derived from petroleum and goes through several refining processes to remove impurities. Mineral oil is suitable for general-purpose applications and works well in low to medium vacuum conditions.

Advantages:

- Cost-effective.

- Readily available.

- Suitable for most common vacuum pump operations.

Disadvantages:

- Limited thermal stability.

- Tends to break down faster compared to synthetic oils.

2. Synthetic Oil

Synthetic oil, such as polyalphaolefin (PAO) oil or ester oil, is specially formulated to withstand higher temperatures and provide better lubrication under extreme conditions. Synthetic oils are used in applications where thermal stability and resistance to oxidation are crucial. They also perform better in pumps exposed to reactive gases or high operating temperatures.

Advantages:

- Excellent thermal stability.

- Longer service intervals compared to mineral oils.

- Suitable for high vacuum conditions.

Disadvantages:

- More expensive than mineral oil.

- May not be compatible with all types of vacuum pumps.

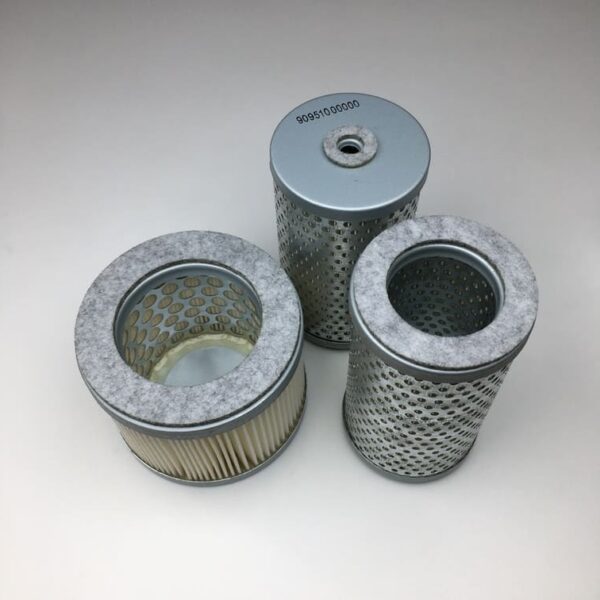

Internal Link: Learn more about oil filters that can extend the life of your vacuum pump’s synthetic oil at Becker Air Filters.

3. Perfluoropolyether (PFPE) Oil

PFPE oil is a specialty oil with exceptional chemical resistance and thermal stability. It is ideal for use in vacuum pumps that operate in highly corrosive or reactive environments. PFPE oils are chemically inert, meaning they can handle exposure to aggressive gases without breaking down or reacting.

Advantages:

- High chemical and thermal stability.

- Compatible with a wide range of gases and chemicals.

- Long oil change intervals.

Disadvantages:

- Expensive.

- Requires specific pump maintenance procedures.

4. Diffusion Pump Oil

Diffusion pump oil is specifically designed for diffusion pumps and is formulated to have very low vapor pressure. This oil is used for achieving ultra-high vacuum levels and can withstand high temperatures without breaking down. Commonly used types of diffusion pump oils are silicone-based and ester-based.

Advantages:

- Suitable for ultra-high vacuum levels.

- Resistant to thermal decomposition.

- Low vapor pressure.

Disadvantages:

- Can be expensive.

- Requires careful handling due to high temperatures.

Internal Link: Discover our full range of 90137301010 Becker Vacuum Vanes for maintaining your vacuum pump system effectively.

How to Choose the Right Vacuum Pump Oil

Selecting the correct vacuum pump oil depends on several factors, including the type of pump, the operating conditions, and the specific application. Here are some important points to consider:

1. Pump Type

The type of vacuum pump you are using largely determines the type of oil you need. Rotary vane pumps typically require mineral or synthetic oils, while diffusion pumps need specialized diffusion oils. Always consult your pump’s manufacturer recommendations to ensure compatibility.

2. Operating Temperature and Pressure

Operating conditions such as temperature and pressure significantly affect the choice of oil. If your pump operates at high temperatures or requires a deep vacuum, synthetic oils or PFPE oils are generally better options. For pumps working at standard conditions, mineral oil may suffice.

3. Chemical Compatibility

Consider the type of gases your pump will be exposed to. Reactive gases may require the use of chemically inert oils, such as PFPE oil, to prevent oil degradation and protect the pump. For general applications, mineral oil may be sufficient.

Quick Tip: Always check for elastomer compatibility when switching to a different oil type to avoid damaging seals and gaskets.

4. Maintenance Requirements

Some oils require more frequent changes and maintenance than others. Mineral oils tend to require more frequent changes due to their limited stability, while synthetic and PFPE oils have longer service intervals. The cost of oil changes should be factored into your decision, as frequent changes can lead to increased maintenance costs.

| Oil Type | Suitable Applications | Change Interval | Cost |

|---|---|---|---|

| Mineral Oil | General use, low to medium vacuum | Short | Affordable |

| Synthetic Oil | High temperature, high vacuum | Moderate | Moderate to high |

| PFPE Oil | Reactive environments | Long | High |

| Diffusion Pump Oil | Ultra-high vacuum | Long | High |

How to Change Vacuum Pump Oil

Regular oil changes are crucial for maintaining vacuum pump performance. Here’s a simple step-by-step guide to help you through the process:

1. Turn Off the Pump

Before changing the oil, ensure that the pump is turned off and cooled down to avoid burns.

2. Drain the Old Oil

Locate the drain plug on the pump and place a suitable container beneath it. Remove the plug and allow the oil to drain completely. This may take several minutes, depending on the pump’s design and oil viscosity.

3. Inspect for Contaminants

Once the oil is drained, inspect it for contaminants such as metal shavings or discoloration. These can indicate wear or other issues within the pump.

4. Refill with New Oil

Replace the drain plug and slowly refill the pump with the appropriate vacuum oil. Use a funnel to prevent spills, and check the oil level indicator to ensure proper filling.

5. Dispose of the Old Oil Properly

Used vacuum pump oil should be disposed of according to local regulations, as it may contain contaminants that are harmful to the environment.

Common Misconceptions About Vacuum Pump Oils

1. “Any Oil Can Be Used in a Vacuum Pump”

Not all oils are created equal. Using an oil that is not formulated for vacuum pumps can result in poor performance, increased wear, and pump damage. Always use oils specifically designed for vacuum pump applications.

2. “Synthetic Oil Is Always Better”

While synthetic oil offers superior thermal stability and longer service intervals, it is not always necessary for every application. Mineral oil can perform just as well in less demanding conditions.

3. “Changing Oil Frequently Is Not Important”

Regular oil changes are crucial for maintaining pump efficiency and longevity. Failure to change the oil can lead to reduced performance, increased wear on internal components, and potential pump failure. Proper maintenance ensures that the pump operates efficiently and lasts longer.