What Material is Used for Rotary Vanes in Pumps and Compressors?

Understanding the Role of Vanes in Rotary Vane Pumps

Rotary vane pumps are a type of positive displacement pump. They work by using a rotor with several slots fitted with vanes that slide in and out. The rotor is offset within a cylindrical housing. As the rotor turns, the vanes maintain contact with the housing wall, creating chambers that vary in size. This action draws fluid or gas into the pump at the inlet and forces it out at the outlet, generating a consistent flow. The vanes play a critical role in this process, as they must maintain a tight seal against the housing to ensure efficient operation and prevent backflow. A rotary vane pump is a marvel of engineering.

Vane pumps are known for their simple design, reliability, and ability to handle a range of fluids and gases. They can generate moderate to high vacuum levels, making them suitable for applications such as vacuum packaging, degassing, and laboratory processes. In addition to vacuum applications, vane pumps are also used to compress gases, finding use in refrigeration, air conditioning, and pneumatic systems. When selecting a rotary vane pump, it’s essential to consider the specific requirements of your application.

The efficiency and longevity of a rotary vane pump depend heavily on the performance of its vanes. Factors such as vane wear, friction, and sealing effectiveness directly impact the pump’s ability to maintain a consistent flow and achieve the desired pressure or vacuum level. Therefore, the choice of vane material is a critical consideration in pump design and operation.

Why Material Selection Matters for Rotary Vanes

The material used for rotary vanes significantly impacts the performance, durability, and maintenance requirements of the pump. Choosing the right vane material is crucial for several reasons:

- Wear Resistance: Vanes are constantly sliding against the pump housing, creating friction and wear. A wear-resistant material ensures that the vanes maintain their shape and sealing effectiveness over time, extending the pump’s lifespan and reducing the need for frequent replacements.

- Friction: The friction between the vanes and the housing affects the pump’s efficiency. Low-friction materials minimize energy loss and heat generation, resulting in smoother operation and reduced power consumption.

- Temperature Resistance: Rotary vane pumps can generate heat during operation, especially at high temperatures. Vane materials must be able to withstand these temperatures without degrading, warping, or losing their mechanical properties. High-temperature applications demand careful material selection.

- Chemical Compatibility: Depending on the application, the pump may handle various fluids or gases, some of which can be corrosive or reactive. The vane material must be compatible with these substances to prevent chemical attacks, swelling, or degradation.

- Lubrication: Some vane materials are self-lubricating, meaning they can reduce friction without external lubricants like oil. This is particularly important in dry-running pumps, where oil contamination is unacceptable.

Selecting a vane material is critical to the overall performance of the rotary vane pump.

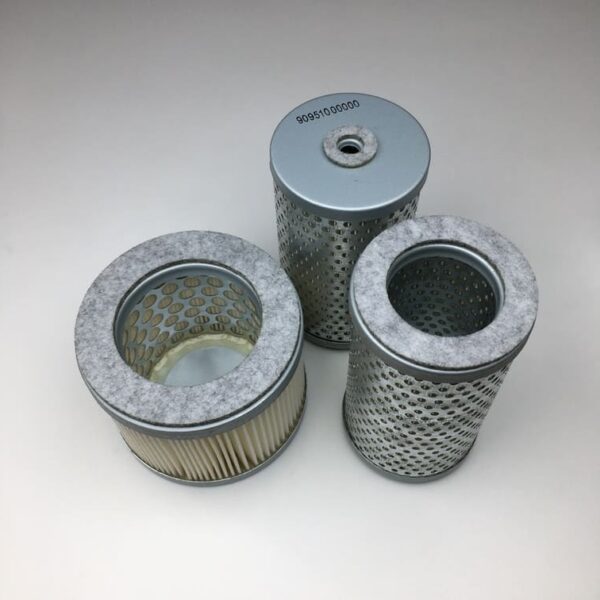

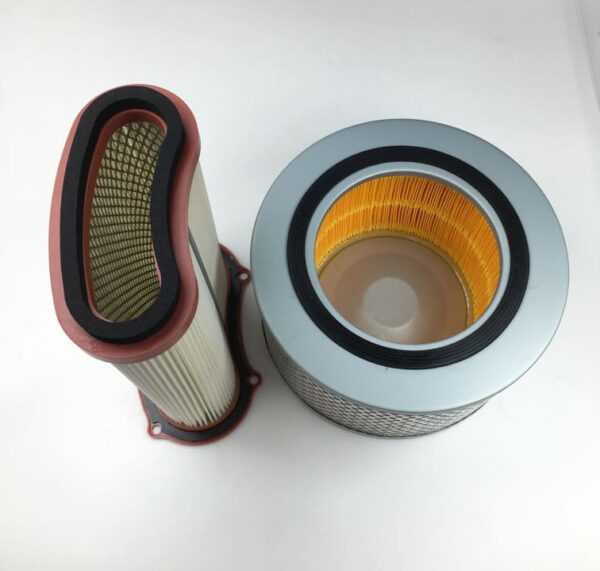

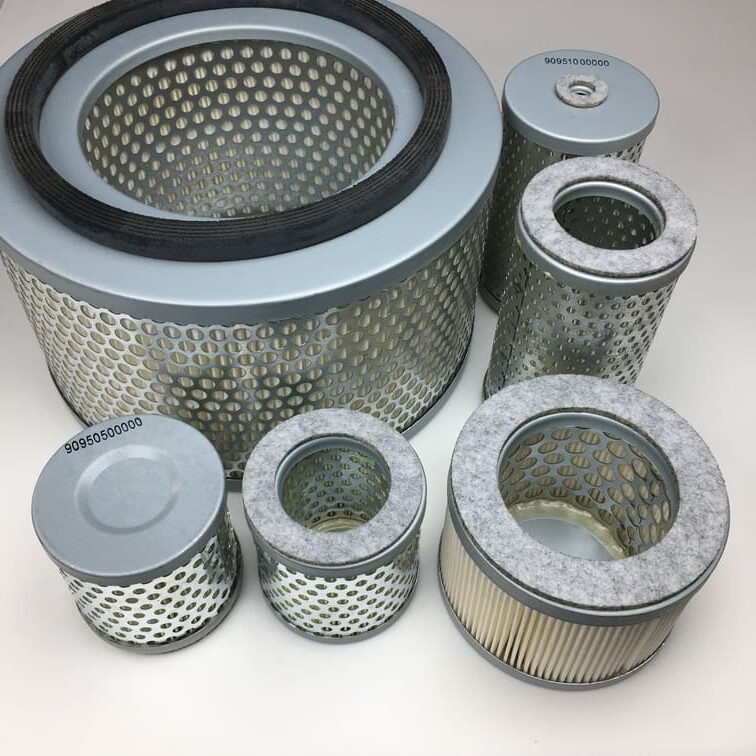

Common Materials Used for Rotary Vanes

Several materials are commonly used for rotary vanes, each with its unique properties and suitability for different applications. Let’s explore some of the most prevalent options:

Carbon Graphite

Carbon graphite is a popular choice for vanes in many rotary vane pumps, especially in dry-running or oil-less designs. Graphite vanes offer several advantages:

- Self-lubricating: Graphite is inherently self-lubricating, meaning it reduces friction without the need for external lubricants. This property makes carbon vanes ideal for applications where oil contamination is a concern, such as in food processing or medical equipment.

- Wear-resistant: Carbon graphite exhibits excellent wear resistance, allowing it to withstand the constant sliding and contact with the pump housing without excessive wear. This contributes to the longevity and reliability of the pump.

- High-temperature capabilities: Carbon can withstand high temperatures without losing its structural integrity or lubricating properties. This makes it suitable for applications involving hot gases or high-temperature environments. In general, carbon graphite offers great temperature capabilities.

- Chemical inertness: Carbon graphite is chemically inert, meaning it does not react with most chemicals. This property makes it suitable for use with a wide range of fluids and gases, including corrosive substances.

Carbon vanes are typically made from a composite material consisting of carbon fibers and a graphite matrix. This combination provides strength, stiffness, and excellent self-lubricating properties. The materials we use are commonly carbon graphite and graphite parts.

Metal Vanes

Metal vanes, made from materials such as cast iron, steel, or bronze, are used in some rotary vane pumps, particularly in oil-lubricated designs. Metal vanes offer high strength and durability, making them suitable for heavy-duty applications. They can withstand high pressures and are less prone to breakage than some other materials.

However, metal vanes require lubrication to reduce friction and wear. This is typically achieved by using an oil-sealed pump design, where the oil provides lubrication and sealing between the vanes and the housing. The amount of oil required depends on the size of the pump and its operating conditions.

Plastic Vanes

Plastic vanes, made from engineering polymers like PEEK (polyether ether ketone) or other high-performance plastics, are used in some rotary vane pumps and compressors. Plastic vanes offer several advantages:

- Lightweight: Plastics are generally lighter than metals, which can be beneficial in applications where weight is a concern.

- Corrosion resistance: Many engineering plastics are highly resistant to corrosion, making them suitable for use with corrosive fluids or gases.

- Self-lubricating: Some plastics, like PEEK, have inherent self-lubricating properties, reducing the need for external lubricants.

- Noise reduction: Plastic vanes can help reduce noise levels compared to metal vanes.

However, plastic vanes may have limitations in terms of temperature and pressure resistance compared to metal or carbon vanes. They may also be more susceptible to wear in abrasive environments. The choice between plastic vanes and other materials depends on the specific requirements of the application.

Factors to Consider When Selecting Vane Material

Choosing the right vane material for your rotary vane pump or compressor involves carefully evaluating several factors:

- Operating Temperature: Consider the expected operating temperature range of your application. Carbon graphite and some metals can handle high temperatures, while certain plastics may have lower temperature limits.

- Pressure or Vacuum Level: The required pressure or vacuum level will influence the choice of vane material. High-pressure applications may require stronger materials like metal, while high-vacuum applications often benefit from the sealing properties of carbon graphite.

- Fluid or Gas Compatibility: Ensure that the vane material is compatible with the fluids or gases being handled. Consider factors such as corrosiveness, reactivity, and viscosity.

- Lubrication: Determine whether your application requires a dry-running or oil-lubricated pump. Self-lubricating materials like carbon graphite are ideal for dry-running pumps, while oil-lubricated pumps may use metal or plastic vanes.

- Maintenance Requirements: Consider the maintenance needs associated with each vane material. Carbon vanes may require less frequent replacement than some plastics, while metal vanes in oil-lubricated pumps require regular oil changes.

- Cost: Balance the upfront cost of the vanes with their expected lifespan and maintenance requirements. Carbon vanes may have a higher initial cost than some plastics but may offer long-term cost savings due to their durability.

- Noise Level: If noise is a concern, consider materials that can help reduce noise, such as some plastics or specially designed carbon composites.

- Wear Resistance: For applications with abrasive particles or high wear potential, choose a vane material with excellent wear resistance, such as carbon graphite or hardened metals.

Manufacturing Process of Carbon Vanes

The manufacturing process of carbon vanes involves several key steps to ensure high quality and performance:

- Material Selection: High-purity graphite and carbon powders are carefully selected based on the desired properties of the final product.

- Mixing: The powders and binders, such as coal tar pitch, are mixed to create a homogeneous blend.

- Molding: The mixture is then molded under high temperature and pressure into the desired vane shape.

- Baking: The molded parts are baked in a furnace to remove volatile components and solidify the structure.

- Graphitization: The parts undergo a high-temperature graphitization process, which enhances their self-lubricating properties, thermal conductivity, and wear resistance.

- Machining: The vanes are precision-machined to their final dimensions and tolerances.

- Impregnation: In some cases, the vanes may be impregnated with resins or metals to further enhance their properties, such as strength or sealing capabilities.

This meticulous process ensures that the carbon vanes meet the stringent requirements for use in demanding rotary vane pump applications.

Applications of Rotary Vane Pumps and Compressors

Rotary vane pumps are used in various industries and applications, including:

- Vacuum Packaging: Creating a vacuum to extend the shelf life of food products.

- Semiconductor Manufacturing: Providing a controlled vacuum environment for various processes.

- Refrigeration and Air Conditioning: Evacuating air and moisture from systems before charging with refrigerant.

- Medical Devices: Powering suction units, wound therapy systems, and other medical equipment.

- Printing: Holding paper in place and transferring ink in printing presses.

- Automotive: Providing vacuum for brake boosters and emission control systems.

- Laboratory: Used in filtration, distillation, degassing, and other laboratory processes.

- Woodworking: Holding workpieces in place on CNC routers and other machinery.

Rotary vane compressors are used in various applications as well, including HVAC systems, industrial gas compression, and pneumatic tools. They are also suitable for applications that require consistent flow.

Maintenance and Troubleshooting of Rotary Vane Pumps

Proper maintenance is essential to ensure the longevity and performance of rotary vane pumps. Regular oil changes (for oil-sealed pumps), filter replacements, and vane inspections are crucial.

Common issues with rotary vane pumps include:

- Reduced vacuum or pressure

- Noisy operation

- Overheating

- Oil leaks (for oil-sealed pumps)

Troubleshooting these problems often involves checking for worn vanes, leaks, clogged filters, or low oil levels. Regular maintenance can prevent many of these issues and keep your pump running smoothly.

FAQs

1. What are the advantages of using carbon vanes in a rotary vane pump?

Carbon vanes offer several advantages, including self-lubrication, excellent wear resistance, high-temperature capabilities, and chemical inertness. They are particularly well-suited for dry-running pumps where oil contamination must be avoided.

2. How often should I replace the vanes in my rotary vane pump?

The frequency of vane replacement depends on factors such as the operating conditions, the vane material, and the type of fluid or gas being handled. Regular inspections can help determine when vane replacement is necessary.

3. Can I use a dry-running rotary vane pump for all applications?

Dry-running pumps are ideal for applications where oil contamination is a concern. However, they may not be suitable for all applications, especially those involving very high pressures or certain types of gases. Consult with a pump expert to determine the best type of pump for your needs.

4. What is the difference between a single-stage and a two-stage rotary vane pump?

A single-stage pump has one rotor and set of vanes, while a two-stage pump has two rotors and sets of vanes arranged in series. Two-stage pumps can achieve deeper vacuum levels than single-stage pumps.

5. How do I know if my rotary vane pump needs maintenance?

Signs that your pump may need maintenance include reduced performance (lower vacuum or pressure), increased noise, overheating, or oil leaks (for oil-sealed pumps). Regular inspections can help identify potential issues before they become major problems.

6. What type of oil should I use in my oil-sealed rotary vane pump?

It’s essential to use the type of oil recommended by the pump manufacturer. Using the wrong oil can lead to performance issues, premature wear, or damage to the pump.

Conclusion

The choice of material for rotary vanes is a critical factor in the performance, efficiency, and longevity of rotary vane pumps and compressors. Carbon graphite is a popular choice due to its unique combination of properties, including self-lubrication, wear resistance, high-temperature capabilities, and chemical inertness. However, other materials like metals and plastics may be more suitable for applications depending on specific requirements. By carefully considering factors such as operating conditions, fluid or gas compatibility, and maintenance needs, you can select the right vane material and ensure optimal performance from your rotary vane pump. Remember, a well-maintained pump with the right components will provide reliable service and contribute to the success of your operations. Hopefully, this has given you a better understanding of what material is used for rotary vanes.

Know More About Us: