What is a Brake Vacuum Pump?

In the world of automotive engineering, a brake vacuum pump is a vital component that significantly impacts the safety and performance of a vehicle. Specifically designed to provide the necessary vacuum pressure to certain systems, the brake vacuum pump plays an important role in boosting braking efficiency, making the driver’s job easier and safer. This article will take a deep dive into the function, importance, and applications of brake vacuum pumps in vehicles, particularly focusing on their usage in systems like brake boosters and power steering. Let’s understand why brake vacuum pumps are crucial, how they work, and how they can enhance your driving experience.

Understanding the Brake Vacuum Pump

A brake vacuum pump is a mechanical or electric device that generates vacuum pressure for various vehicle systems. The primary function of this pump is to create the vacuum necessary to operate the brake booster, which, in turn, assists in braking with minimal pedal effort.

Key Types of Brake Vacuum Pumps:

- Mechanical Vacuum Pumps: These pumps are engine-driven, typically powered by the camshaft or crankshaft. They rely on the engine’s speed to create vacuum pressure.

- Electric Vacuum Pumps: These pumps operate independently of the engine, powered by the vehicle’s electrical system. They are often found in hybrid or electric vehicles where an engine-driven pump is not viable.

The generated vacuum aids several functions, but the main focus is enhancing the performance of the brake booster—a crucial element in providing smooth and effective braking.

The Importance of the Brake Booster

What is a Brake Booster?

The brake booster is a device located between the brake pedal and the master cylinder. Its main job is to multiply the force applied by the driver to the brake pedal, reducing the effort needed to stop the car. Without a brake booster, you would need to apply significantly more force to the pedal, which could be exhausting and even dangerous in emergency situations.

- Brake Booster and Vacuum: The brake booster relies on a consistent vacuum supply to function effectively. This vacuum is generally created by the engine itself in naturally aspirated vehicles. However, turbocharged or diesel engines—and even electric vehicles—often do not generate enough natural vacuum. This is where the brake vacuum pump steps in to provide the necessary pressure.

- Safety and Comfort: With the brake booster receiving adequate vacuum pressure, braking becomes easier, more responsive, and safer. This is particularly critical in heavier vehicles or those that require more precise control during braking, such as trucks or SUVs.

How Brake Vacuum Pumps Support Brake Boosters

Brake vacuum pumps are instrumental in ensuring the brake booster operates correctly, particularly under various conditions where natural vacuum supply may be insufficient. These pumps ensure that, even when the engine is at low RPMs or when driving at high altitudes, the brake booster gets enough vacuum pressure to work effectively.

- Low RPM Scenarios: At low engine speeds, natural vacuum pressure drops. The vacuum pump compensates for this by maintaining consistent pressure, ensuring effective braking regardless of the engine speed.

- Power Steering Support: In some vehicles, the vacuum pump also provides support to the power steering system. It ensures there is adequate hydraulic pressure for smooth and easy maneuvering, making driving a lot more comfortable.

Types of Brake Vacuum Pumps and Their Mechanisms

Mechanical Brake Vacuum Pumps

Mechanical brake vacuum pumps are driven by the engine, usually through a belt or camshaft. They work in synchronization with the engine’s speed, which means the vacuum generated is proportional to how fast the engine is running.

Advantages of Mechanical Pumps:

- Simplicity: Mechanical pumps are relatively simple in design and easy to install.

- Dependability: With fewer electronic components, mechanical pumps tend to be durable and less prone to electronic failures.

Disadvantages:

- Inconsistent Vacuum at Low RPM: Since mechanical pumps are engine-dependent, they may produce less vacuum at lower RPMs, which can be a limitation during idling or slow-speed driving.

- Energy Efficiency: These pumps create additional load on the engine, which can reduce overall fuel efficiency.

Electric Brake Vacuum Pumps

Electric brake vacuum pumps are designed to overcome the limitations of mechanical pumps. Powered by the vehicle’s electrical system, they operate independently of the engine, making them ideal for modern vehicles, especially hybrid and electric cars.

Advantages of Electric Pumps:

- Consistent Vacuum Supply: They provide a consistent vacuum regardless of engine speed, ensuring reliable braking performance at all times.

- Energy Efficiency: These pumps operate on demand, meaning they only consume power when needed, improving overall energy efficiency.

- Compatibility with Modern Technology: Electric pumps are better suited for modern technologies like start-stop systems, which shut off the engine at traffic lights to save fuel.

Disadvantages:

- Complexity: Electric pumps have more components, such as sensors and electronic controls, making them more complex to install and repair.

- Cost: They are typically more expensive than mechanical vacuum pumps due to their advanced technology.

How Brake Vacuum Pumps Affect Driving Safety and Comfort

Enhanced Braking Efficiency

The primary advantage of having a brake vacuum pump is the enhanced braking efficiency it provides. With the correct vacuum pressure available at all times, the brake booster is able to multiply the braking force effectively, resulting in quicker stopping times and increased safety.

- Emergency Braking: During sudden braking scenarios, the vacuum pump ensures that the brake booster receives the pressure it needs to assist the driver effectively, reducing stopping distances.

- Heavy Vehicles: In larger vehicles, the role of a vacuum pump becomes even more important. More mass means more inertia, and having a brake vacuum pump ensures the braking system can handle this effectively.

Improved Power Steering Functionality

In some setups, the vacuum pump also assists in regulating the power steering system. Consistent hydraulic pressure is necessary for power steering to function smoothly, and the vacuum pump’s role in this process ensures that drivers have better control over their vehicles, especially when maneuvering at low speeds or during parking.

- Lower Steering Effort: A functional vacuum pump makes power steering more effective, thereby reducing the amount of effort needed to turn the wheel.

- Precision Handling: By ensuring consistent pressure, the vacuum pump contributes to more precise steering, which is beneficial for performance and safety.

Common Issues with Brake Vacuum Pumps

Signs of a Faulty Brake Vacuum Pump

Over time, brake vacuum pumps can wear out or develop issues that affect their performance. Recognizing the signs of a faulty brake vacuum pump early can prevent dangerous driving conditions.

Common Symptoms of a Faulty Pump:

- Hard Brake Pedal: If the brake pedal becomes harder than usual, it could indicate that the vacuum pump is not providing sufficient pressure to the brake booster.

- Increased Stopping Distance: When the vacuum pump malfunctions, the brake booster does not operate efficiently, leading to longer stopping distances.

- Noisy Pump: A loud, rattling noise from the pump area often signals internal wear or damage. It’s best to have the pump inspected and replaced if necessary.

- Engine Light: Some modern vehicles are equipped with sensors that can detect vacuum pump issues and trigger the check engine light. Pay attention to dashboard warnings.

Maintenance and Replacement Tips

Regular maintenance of the brake vacuum pump is essential to ensure safety and performance:

- Routine Inspections: Check vacuum hoses for leaks or cracks regularly. Damaged hoses can reduce the effectiveness of the vacuum pump.

- Listen for Unusual Noises: Unusual sounds, like rattling or knocking, could indicate wear and should be addressed immediately.

- Replace When Necessary: A failing brake vacuum pump should be replaced without delay, as it directly impacts braking efficiency and safety.

How to Diagnose and Replace a Faulty Brake Vacuum Pump

Diagnosing Brake Vacuum Pump Issues

If you suspect your brake vacuum pump may be faulty, there are a few steps you can take to diagnose the problem:

- Brake Pedal Test: Start the engine and press the brake pedal. If it feels hard, it could indicate a vacuum pump issue.

- Vacuum Gauge Test: Use a vacuum gauge to measure the pressure. A significant drop in vacuum levels indicates that the pump is not operating efficiently.

- Check Engine Codes: Use an OBD-II scanner to check for error codes that may indicate a vacuum system issue.

Replacing the Brake Vacuum Pump

If the brake vacuum pump is confirmed to be faulty, it’s time to replace it. While it is recommended to have this procedure done by a professional mechanic, here’s a general overview:

- Disconnect Battery: Safety first! Disconnect the vehicle’s battery to avoid accidental starts.

- Locate the Pump: Find the vacuum pump, which is typically located near the engine or directly attached to it.

- Disconnect Hoses and Wiring: Carefully disconnect all vacuum hoses and electrical connectors.

- Remove the Old Pump: Unbolt the pump from its mounting bracket and remove it.

- Install the New Pump: Fit the new vacuum pump into place, connect all hoses, wires, and tighten the bolts securely.

- Test the Braking System: Once installed, reconnect the battery and test the brakes to ensure everything is functioning as expected.

Frequently Asked Questions

1. What is the role of a brake vacuum pump in my vehicle?

The brake vacuum pump generates vacuum pressure for the brake booster, which helps reduce the effort needed to apply the brakes. It ensures that braking is responsive and efficient.

2. How do I know if my brake vacuum pump is failing?

Symptoms of a failing brake vacuum pump include a hard brake pedal, increased stopping distance, unusual noises, or a dashboard warning light. Regular inspections can help catch these issues early.

3. Are electric brake vacuum pumps better than mechanical ones?

Electric pumps offer more consistent vacuum pressure and energy efficiency, particularly in hybrid or start-stop vehicles, whereas mechanical pumps are simpler but depend on engine speed.

4. Can I drive with a faulty brake vacuum pump?

It is unsafe to drive with a faulty brake vacuum pump as it affects brake booster efficiency. This leads to harder braking and increased stopping distance, putting you at risk.

5. How often should a brake vacuum pump be replaced?

A brake vacuum pump doesn’t have a specific replacement schedule but should be replaced as soon as signs of failure are noticed to maintain safety and performance.

Conclusion

A brake vacuum pump is an essential component of modern automotive braking systems, ensuring that brake boosters receive the necessary vacuum pressure to function effectively. Whether driven mechanically by the engine or electrically powered, these pumps enhance the safety, performance, and comfort of driving. Regular maintenance, early detection of faults, and prompt replacement are key to keeping your vehicle’s braking system in top condition. Properly functioning brake vacuum pumps not only make driving easier but also significantly reduce the risks associated with emergency braking.

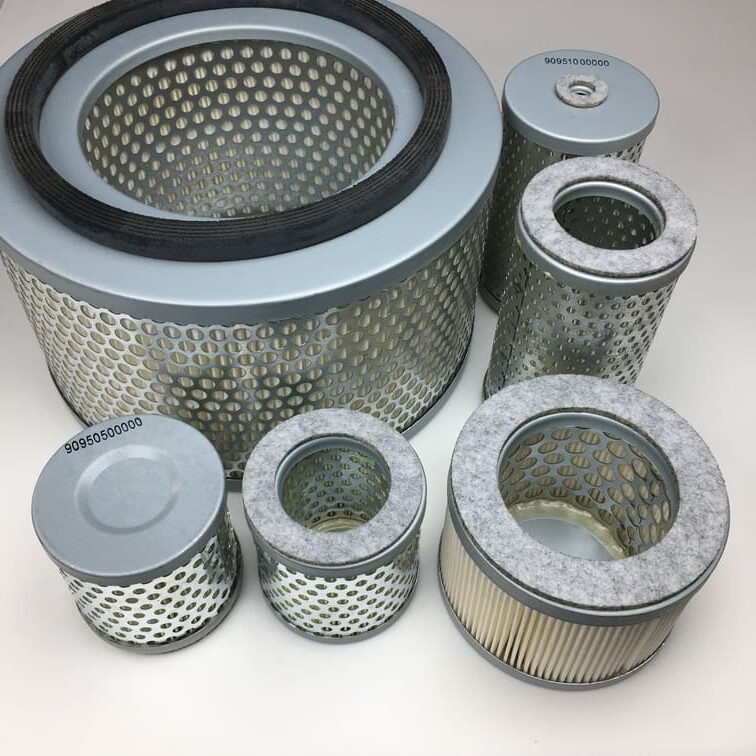

If you are looking for high-quality brake vacuum pump parts or other vacuum pump components, check out 90138800005 | WN 124-220 Original Becker Set of 5 Vanes or Becker Air Filter replaces Becker 909540 for reliable options that will keep your system running smoothly. Investing in original, quality components is a sure way to enhance safety and longevity for your vehicle’s braking system.