What Does the Vacuum Pump Do on a 6.5 Diesel?

The vacuum pump on a 6.5 diesel engine serves an essential function in ensuring that various components of the vehicle operate smoothly. Unlike traditional gas engines, diesel engines do not generate enough natural vacuum to support certain components, making a dedicated vacuum pump necessary. This article delves into the role of the vacuum pump in a 6.5 diesel, its various applications, and what size pump is suitable for particular purposes. Understanding the importance of this component is crucial for maintaining the performance and reliability of your diesel vehicle.

The Role of a Vacuum Pump in Diesel Engines

Diesel engines, such as the 6.5-liter GM diesel, differ fundamentally from gasoline engines in terms of how they manage air intake and exhaust. Diesel engines lack the natural vacuum found in gasoline engines because of the way they control air. In a diesel engine, the throttle plate, which in gasoline engines creates the vacuum when partially closed, is absent. Therefore, a vacuum pump is needed to perform functions that rely on vacuum power.

Vacuum Creation for Power Accessories

The vacuum pump creates a consistent vacuum for powering several critical systems and accessories, including:

- Brake Booster: Most diesel engines, including the 6.5 diesel, rely on vacuum-assisted braking. The vacuum pump supplies the needed vacuum to the brake booster, enhancing the force applied to the brakes and making braking much easier.

- HVAC Controls: The HVAC system in many vehicles requires vacuum to operate blend doors and valves. The vacuum pump provides this vacuum to control the temperature and airflow direction.

- Emission Control Systems: In some cases, vacuum is used to control emission components to ensure the vehicle remains compliant with environmental standards.

Differences Between Gasoline and Diesel Vacuum Requirements

- Gasoline Engines: These engines generate natural vacuum as part of their air intake process. The throttle valve restricts airflow, creating a vacuum that can be utilized by various systems.

- Diesel Engines: Diesel engines do not have a throttle plate and instead control power through fuel injection, which means they do not generate vacuum in the same way, hence the need for a dedicated vacuum pump.

The Importance of the Vacuum Pump in a 6.5 Diesel

A vacuum pump in a 6.5 diesel engine is crucial for driving key systems. Without it, the power-assisted braking system wouldn’t function efficiently, leading to increased braking distances and an overall unsafe driving experience. Additionally, other comfort and performance systems like the HVAC would be severely compromised, affecting the comfort and functionality of the vehicle.

Types of Vacuum Pumps Used in Diesel Engines

1. Mechanical Vacuum Pumps

Mechanical vacuum pumps are typically driven by the engine’s timing gear or camshaft. They use mechanical power from the engine to create the necessary vacuum.

- Advantages: Mechanical pumps are robust and usually require less frequent maintenance compared to their electric counterparts. They are a common choice for older diesel engines, like the 6.5 diesel.

- Disadvantages: Since these pumps are mechanically driven, they add to the engine’s load and may not be as efficient as newer electric models.

2. Electric Vacuum Pumps

Electric vacuum pumps are newer alternatives that run independently of the engine, powered by the electrical system of the vehicle.

- Advantages: Electric pumps can maintain vacuum levels regardless of the engine’s RPM. This results in consistent braking power and performance for accessories.

- Disadvantages: They require electrical power, which can impact battery performance and charging system load.

Common Problems and Solutions for Vacuum Pumps on a 6.5 Diesel

1. Loss of Brake Power Assist

One of the most apparent signs of a failing vacuum pump is a loss of power assist in braking. If the brake pedal becomes hard to press, it could mean that the vacuum pump is not creating enough vacuum to supply the brake booster.

- Solution: Check the vacuum lines for cracks or leaks. If the lines are intact, the vacuum pump itself may need replacement. Routine maintenance and timely inspection can help prevent these issues.

2. Poor HVAC System Performance

A malfunctioning vacuum pump can lead to poor performance of the HVAC system, resulting in inability to change airflow direction or temperature control failure.

- Solution: Inspect the vacuum pump and associated vacuum lines for any wear or damage. In some cases, replacing a faulty vacuum solenoid may also be necessary.

3. Emission System Malfunctions

For vehicles using vacuum-based emission control systems, a failing vacuum pump can lead to increased emissions and possible failure to meet inspection standards.

- Solution: Replace any vacuum hoses or check valves that may be leaking or broken. If the problem persists, inspect the vacuum pump for wear.

How to Choose the Right Vacuum Pump for a 6.5 Diesel

1. Capacity and Requirements

The vacuum pump capacity should be suitable for the requirements of the vehicle. The key factors include:

- Flow Rate: Measured in cubic feet per minute (CFM), the flow rate determines how quickly the pump can create a vacuum. A standard flow rate for a diesel vacuum pump in a vehicle like a 6.5 diesel is typically around 3-6 CFM.

- Vacuum Level: The ability to create a vacuum depth of 20-25 inHg (inches of mercury) is generally sufficient for automotive applications, such as powering brake boosters and HVAC systems.

2. Durability and Maintenance Needs

The pump should be durable enough to withstand the engine’s heat and vibration. Mechanical pumps generally have fewer moving parts but still require periodic lubrication and maintenance to stay efficient.

- Material Considerations: Look for pumps made from heat-resistant metals or composites. The carbon vanes inside a mechanical pump are particularly prone to wear, so replacements are essential for long-term durability.

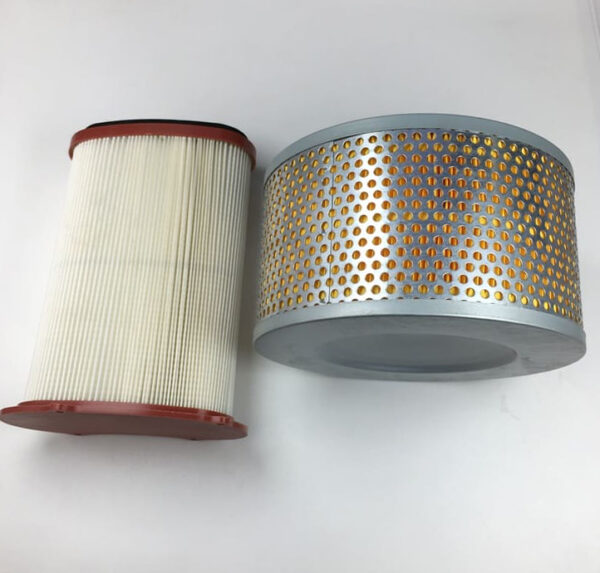

For more information about Becker air filters that may be used alongside vacuum pumps for effective filtration, visit Becker Air Filter Products.

3. Replacement Considerations

If your 6.5 diesel vacuum pump fails, finding a replacement that fits the same mounting points and offers similar performance is crucial.

- Original Equipment Manufacturer (OEM) pumps are usually recommended as replacements for reliability and compatibility.

- If you opt for aftermarket options, ensure that they match the specifications, such as pressure and flow rates, to maintain system efficiency.

Vacuum Pump Maintenance for a 6.5 Diesel

To keep the vacuum pump on your 6.5 diesel functioning optimally, regular maintenance is key.

- Inspect Vacuum Lines: The vacuum lines are prone to cracking due to age and heat. Regular inspection can prevent vacuum loss.

- Listen for Unusual Noises: A worn pump will often make strange rattling or clunking noises, indicating that it may be time for a replacement.

- Oil Maintenance: If your vehicle uses an oil-sealed pump, regular oil changes are necessary to keep it lubricated and functioning well.

Explore more vacuum pump maintenance tools and spare parts at Vacuum Pump Parts for guidance and essential components.

How the Vacuum Pump Improves Diesel Performance

The vacuum pump significantly impacts overall vehicle performance, specifically focusing on safety and comfort features.

- Braking System: By powering the brake booster, the vacuum pump ensures that stopping the vehicle requires less effort, improving driving safety.

- HVAC Efficiency: Effective vacuum supply to HVAC controls leads to consistent cabin comfort, a key aspect in any driving experience.

- Emission Control: Proper functioning of emission control systems due to vacuum supply helps the vehicle stay compliant with emission regulations, reducing environmental impact.

FAQs

1. Why does a 6.5 diesel need a vacuum pump?

A 6.5 diesel needs a vacuum pump because diesel engines do not naturally produce vacuum pressure needed for systems like the brake booster and HVAC controls.

2. What are signs of a failing vacuum pump?

Signs of a failing vacuum pump include a hard brake pedal, poor HVAC performance, and increased emissions. You may also hear unusual noises coming from the pump.

3. Can I use an electric vacuum pump on a 6.5 diesel?

Yes, an electric vacuum pump can be used on a 6.5 diesel, especially for consistent vacuum at lower RPMs. However, this may require modifications to the electrical system.

4. How often should I replace the vacuum pump on my 6.5 diesel?

There is no fixed schedule, but vacuum pumps generally last 5-7 years or more depending on usage. Regular inspections can help determine when a replacement is needed.

5. What size vacuum pump is best for a 6.5 diesel?

A pump with a capacity of 3-6 CFM and the ability to reach a vacuum level of 20-25 inHg is typically sufficient for a 6.5 diesel.

Conclusion

The vacuum pump on a 6.5 diesel engine is an indispensable component, playing a vital role in powering the brake booster, HVAC, and emissions systems. Without it, the overall safety and comfort of the vehicle would be severely compromised. Understanding how to choose, maintain, and recognize issues with the vacuum pump ensures that your diesel engine continues to run smoothly, offering safety and reliability.

Whether you are replacing a faulty pump or simply ensuring that the existing one is in optimal condition, knowing its role and requirements can prevent significant future issues. If you’re looking for high-quality vacuum pump parts and maintenance tools, consider visiting Vacuum Pump Spare Parts. Having the right tools and parts ensures your vehicle’s systems work efficiently, keeping you and your passengers safe on the road.