What Causes White Milky Vacuum Pump Oil?

Vacuum pump oil plays a crucial role in ensuring the proper function of vacuum pumps. However, sometimes users may observe a concerning issue: white milky vacuum pump oil. This phenomenon can be alarming, especially when you consider the impact it may have on the longevity and efficiency of your equipment. In this article, we will explore the potential causes behind this problem, how to address it, and ways to prevent it from happening.

Understanding Vacuum Pump Oil

What Is Vacuum Pump Oil?

Vacuum pump oil is a specially formulated lubricant that serves multiple purposes in vacuum systems. It aids in reducing friction, sealing gaps, and maintaining vacuum levels by efficiently removing air molecules. Unlike other types of oil, vacuum pump oil is designed to withstand high temperatures and prevent the formation of sludge or contamination.

- Lubrication: Minimizes wear and tear on moving parts within the pump.

- Sealing: Forms a tight seal that enhances vacuum efficiency.

- Cooling: Helps in dissipating heat generated during pump operation.

The quality of vacuum pump oil directly impacts the performance of a vacuum system. High-quality oil contributes to consistent suction and a longer lifespan of the pump.

Why Does Vacuum Pump Oil Turn Milky?

The change in the oil’s appearance is usually indicative of contamination, most commonly with water or another incompatible substance. This milky discoloration, often described as “emulsification,” can be caused by several factors. Understanding these factors will help you address the problem and prevent further damage.

Causes of White Milky Vacuum Pump Oil

1. Water Contamination

The most common reason for vacuum pump oil turning milky is water contamination. When moisture or water mixes with the oil, it forms a milky emulsion that negatively affects the efficiency of the pump.

How Does Water Enter the System?

- Atmospheric Humidity: When operating in environments with high humidity, moisture can enter the pump through the air intake.

- Condensation: In low-temperature environments, condensation within the pump can lead to water entering the oil.

2. Chemical Contaminants

Chemical contamination can also cause the oil to turn milky. This could result from reactive vapors or gases that mix with the oil during pumping operations. Certain chemicals may form insoluble emulsions or interact with the oil, leading to a milky appearance.

Examples of Chemical Contaminants:

- Acids: If the vacuum pump is used in a lab or chemical facility, residual acids might enter the pump and react with the oil.

- Solvents: Organic solvents may have the same emulsifying effect, especially if they are partially water-soluble.

3. Overheating and Oxidation

Another potential cause of milky vacuum pump oil is overheating. When vacuum pumps run at high temperatures for extended periods, the oil can degrade and react with oxygen, resulting in emulsification and discoloration.

- Oxidation: Exposure to oxygen at elevated temperatures causes the oil to break down and form an emulsion, appearing milky.

- Poor Cooling: Ineffective cooling mechanisms can exacerbate overheating, increasing the rate at which oil oxidizes.

4. Incorrect Oil Use

Using an incompatible type of oil can also lead to issues. If an oil not specifically formulated for vacuum pumps is used, it may react with residual moisture or contaminants within the pump and turn milky.

Tip: Always use vacuum pump oil recommended by the manufacturer to avoid issues related to viscosity and compatibility.

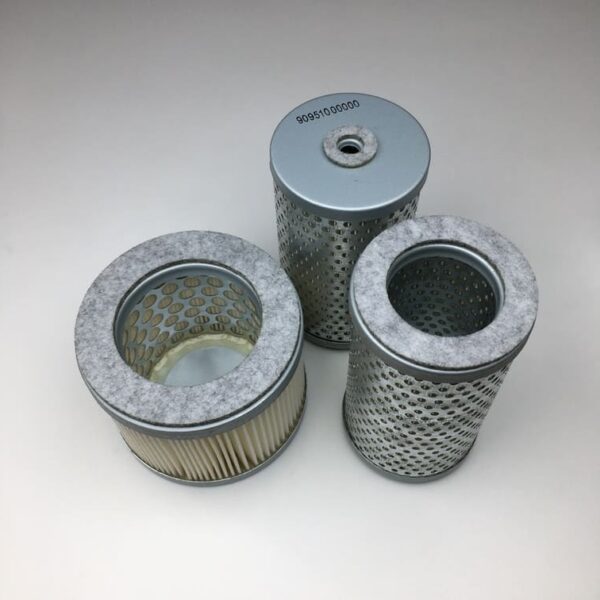

(Becker Air Filter replaces Becker 909540 – an essential component for proper pump maintenance)

(Becker Air Filter replaces Becker 909540 – an essential component for proper pump maintenance)

Impacts of Milky Oil on Vacuum Pump Performance

1. Reduced Lubrication Efficiency

When vacuum pump oil turns milky, its lubrication properties are compromised. The presence of water or chemical contaminants means the oil cannot create a consistent film around moving parts, leading to increased friction.

- Friction-Related Damage: Increased friction results in faster wear and tear, reducing the pump’s lifespan.

- Increased Maintenance: More frequent replacement of parts may be required due to inadequate lubrication.

2. Loss of Vacuum Integrity

Vacuum pump oil is essential for maintaining a tight seal. Milky oil often lacks the viscosity required to form an effective seal, which leads to poor vacuum performance and a reduction in the system’s ability to reach optimal pressure.

- Leakage: The improper sealing could result in air leaks, making it challenging for the pump to maintain a consistent vacuum level.

3. Corrosion and Chemical Damage

Contaminated oil can cause internal corrosion. If acids or other chemicals are present, they can damage metal components, leading to irreversible damage and costly repairs.

Quick Insight: A regular check for milky oil can help prevent long-term damage to your vacuum pump and extend its operational lifespan.

How to Address White Milky Vacuum Pump Oil

1. Regular Monitoring and Maintenance

Routine checks of vacuum pump oil can help identify issues early before significant damage occurs. Regular inspection helps you determine when to replace the oil or whether additional preventive measures are needed.

- Daily Oil Check: Check the oil for any color changes, particularly a milky or cloudy appearance.

- Scheduled Oil Change: Replace vacuum pump oil according to manufacturer recommendations or more frequently if contamination is detected.

2. Oil Changes with Quality Replacement Products

If the oil has turned milky, an oil change is crucial. Be sure to drain the contaminated oil completely before adding new oil.

- Flush the System: When changing oil, flush the pump to remove all residual contamination.

- Use Proper Oil: Ensure that you use high-quality oil specifically formulated for your vacuum pump model. For details on proper replacement products, check out Vacuum Pump Spare Parts.

3. Install an Air Filter or Gas Ballast

To minimize moisture contamination, install an air filter or use a gas ballast valve. These components help reduce moisture build-up by allowing some water vapor to vent before it condenses and contaminates the oil.

- Gas Ballast Valve: This feature helps in expelling water vapor during operation, significantly reducing moisture ingress into the oil.

(Becker Set of 5 Vanes – critical for maintaining effective vacuum pump operation)

(Becker Set of 5 Vanes – critical for maintaining effective vacuum pump operation)

Preventing Milky Oil: Best Practices

1. Control Operating Environment

Operating a vacuum pump in a controlled environment can significantly reduce the chances of contamination.

- Temperature and Humidity: Keep humidity levels as low as possible, and avoid drastic temperature changes that can cause condensation.

- Prevent Direct Exposure: If possible, position the pump in an area where exposure to contaminants like water or chemicals is minimized.

2. Proper Handling and Storage of Vacuum Oil

Always store vacuum pump oil in a sealed container in a cool and dry environment. Exposure to open air can lead to moisture absorption before the oil is even used.

3. Use the Gas Ballast Correctly

If your vacuum pump is equipped with a gas ballast valve, use it properly. When operating in environments prone to moisture, opening the gas ballast periodically can help eliminate vapor and maintain the quality of the oil.

Key Point: Understanding the purpose and correct use of the gas ballast can make a significant difference in preventing water contamination.

Frequently Asked Questions

1. Why does my vacuum pump oil look milky?

Milky vacuum pump oil typically indicates water or chemical contamination. This can happen due to condensation, high atmospheric humidity, or exposure to incompatible substances.

2. How often should I change the oil in my vacuum pump?

The frequency of oil changes depends on your usage and the environment. In general, manufacturers recommend oil changes after every 300 hours of operation or sooner if contamination is evident.

3. Is milky vacuum pump oil harmful to the pump?

Yes, milky oil compromises the pump’s performance by reducing lubrication, sealing efficiency, and causing potential corrosion.

4. Can I use any oil in my vacuum pump?

No, only specific vacuum pump oils should be used. Using incorrect oil may lead to compatibility issues, inadequate lubrication, and eventually, pump failure.

5. What role does the gas ballast valve play in preventing milky oil?

The gas ballast valve allows moisture to vent from the vacuum chamber before it condenses into the oil, thus helping prevent milky oil.

Conclusion

White milky vacuum pump oil is a clear indicator that something has gone wrong, usually involving contamination from moisture or other chemicals. Such contamination impacts the performance of your pump, leading to reduced lubrication, poor sealing, and potential corrosion. By understanding the causes, impacts, and solutions, you can prevent costly damages and keep your vacuum pump operating efficiently.