What Are the Uses of Carbon Vanes?

Carbon vanes are essential components in various industrial applications, particularly in the realm of vacuum technology. Their unique properties make them ideal for use in vacuum pumps and compressors. But what are the uses of carbon vanes specifically? This article will explore the diverse applications of carbon vanes, providing a comprehensive overview of their function, benefits, and why they are a preferred choice in numerous industries. We’ll examine how these seemingly simple parts play a critical role in complex systems and why their specific characteristics make them indispensable in certain applications.

Understanding Carbon Vanes and Their Properties

Carbon vanes are primarily used in rotary vane vacuum pumps and compressors. These vanes are made from carbon graphite, a material known for its exceptional self-lubricating properties, high-temperature resistance, and mechanical strength. In a vane pump, these carbon vanes are fitted into slots within a rotor. As the rotor spins, the vanes slide in and out, maintaining contact with the pump housing. This creates a seal and forms chambers that change in volume, enabling the pump to move air or gas, thus generating a vacuum. The ability of carbon graphite to withstand wear and tear while operating under varied pressure and temperature conditions makes it an ideal material for vanes. Carbon vanes offer a reliable solution.

The Role of Carbon Vanes in Vacuum Pumps

In vacuum pumps, carbon vanes are crucial for creating and maintaining a vacuum. They do this by forming a seal between the rotating rotor and the stationary housing of the pump. As the rotor spins, the vanes slide outwards due to centrifugal force, pressing against the pump housing to create sealed chambers. These chambers trap and move air or gas from the inlet to the outlet, effectively generating a vacuum. This is why carbon vanes are a common sight in vacuum pumps. The efficiency of a vacuum pump heavily relies on the integrity and performance of its vanes. Carbon vane vacuum technology is crucial in many industries. The quality of these carbon graphite vanes directly impacts the pump’s performance and lifespan. For example, using high-quality vanes like the 90133000007 | WN 124-034 Original Becker Set of 7 Vanes can significantly improve pump efficiency.

Key Applications of Carbon Vanes in Various Industries

Carbon vanes are utilized across a broad spectrum of industries due to their unique properties. Here are some key applications:

- Printing and Packaging: Vacuum pumps with carbon vanes are extensively used in printing presses and packaging machinery to handle paper, create suction for feeding and stacking, and ensure precise alignment of materials.

- Food Processing: Carbon vane vacuum pumps play a vital role in food packaging, vacuum sealing, and degassing liquids, helping maintain product freshness and extend shelf life.

- Medical and Laboratory Equipment: Vane pumps are employed in medical devices such as aspirators, suction units, and laboratory equipment requiring controlled vacuum environments.

- Woodworking: Vacuum pumps with carbon vanes are used in CNC routers and vacuum presses for clamping, veneering, and forming wood components.

- Plastics Manufacturing: These pumps are essential in processes like vacuum forming, thermoforming, and degassing of plastics.

- Chemical and Pharmaceutical: Carbon vane pumps handle corrosive or sensitive gases and vapors in chemical processing and pharmaceutical manufacturing.

- Environmental Technology: They are used in soil remediation, groundwater sampling, and other environmental applications requiring reliable vacuum generation.

These are just a few examples of the many versatile applications of carbon vanes in various sectors.

Advantages of Using Carbon Graphite Vanes

The use of carbon graphite vanes offers several advantages:

- Self-Lubricating: Carbon graphite is inherently self-lubricating, reducing friction and wear, and eliminating the need for oil in oil-less or dry-running pumps.

- High-Temperature Resistance: Carbon graphite can withstand high operating temperatures without losing its structural integrity.

- Chemical Resistance: Carbon vanes are resistant to a wide range of chemicals, making them suitable for use in corrosive environments.

- Dimensional Stability: Carbon graphite maintains its shape and size under varying temperatures and pressures, ensuring consistent pump performance.

- Durability: Carbon vanes are durable and long-lasting, contributing to the overall reliability of the pump.

These properties make carbon graphite vanes an excellent choice for demanding applications.

Comparing Carbon Vanes with Other Vane Materials

While carbon vanes are prevalent, other materials like cast iron, steel, and composites are also used for pump vanes. However, carbon graphite offers a unique combination of properties that make it superior in many applications:

| Property | Carbon Graphite Vanes | Metal Vanes | Plastic/Composite Vanes |

|---|---|---|---|

| Self-Lubricating | Yes | No (require oil lubrication) | Some, but not as effective as carbon |

| Temperature Resistance | High | High, but can be affected by oil breakdown at high temperatures | Limited temperature range |

| Chemical Resistance | Excellent | Dependent on the specific metal | Varies depending on the material |

| Wear Resistance | Good | Good, but can cause more wear on the pump housing | Can be lower than carbon or metal, especially at high speeds |

| Cost | Moderate to High | Moderate | Low to Moderate |

Carbon graphite strikes a balance between performance, durability, and cost-effectiveness.

Maintenance and Replacement of Carbon Vanes

Proper maintenance is crucial for maximizing the lifespan of carbon vanes and ensuring optimal pump performance. Regular inspection of vane thickness and surface condition is essential. Vanes should be replaced when they reach the minimum thickness specified by the manufacturer or when signs of excessive wear or damage are observed. Using genuine replacement parts, such as the 90132500005 | WN 124-250 Original Becker Set of 5 Vanes, ensures compatibility and performance.

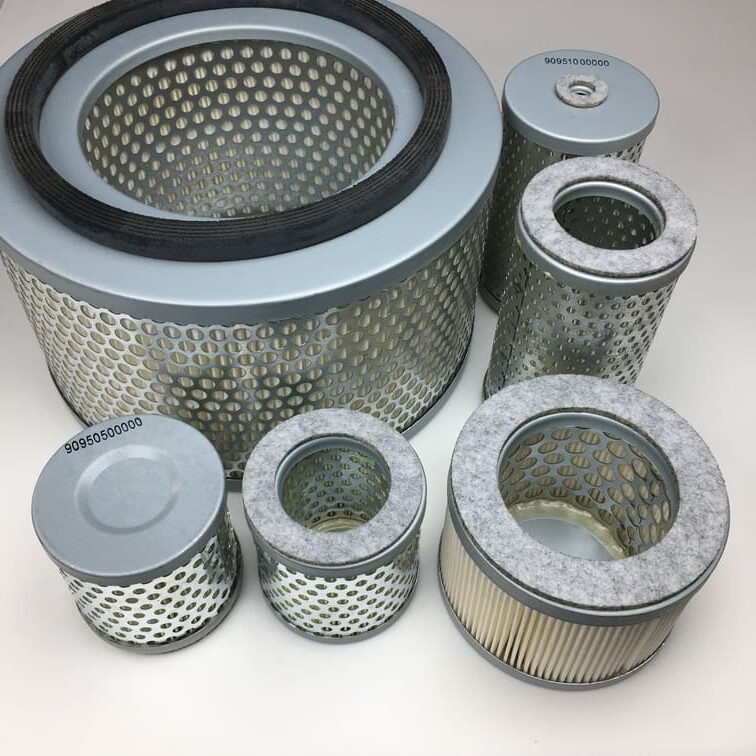

It’s also important to keep the pump clean and free of debris that could accelerate vane wear. Proper filter maintenance, like using a quality Becker Air Filter replaces Becker 909540, can help prevent contaminants from entering the pump.

Innovations in Carbon Vane Technology

The field of carbon vane technology continues to advance. Researchers and manufacturers are constantly exploring new formulations and manufacturing techniques to improve vane performance further. Some areas of innovation include:

- Advanced Carbon Composites: Development of new carbon composite materials with enhanced strength, wear resistance, and thermal properties.

- Nanotechnology: Incorporating nanomaterials into carbon matrices to improve lubrication and reduce friction.

- Surface Treatments: Applying specialized coatings to vanes to enhance their performance in specific environments.

- Optimized Vane Designs: Using computer modeling and simulation to develop more efficient vane geometries.

These innovations aim to extend vane life, improve pump efficiency, and expand the range of applications for carbon vane vacuum pumps. The technology behind these components is constantly evolving. Another example of a high-quality replacement part is the 90132400007 | WN 124-249 Original Becker Set of 7 Vanes.

FAQs

1. How long do carbon vanes typically last?

The lifespan of a carbon vane depends on several factors, including operating conditions, pump design, maintenance practices, and the quality of the vane material. Under normal operating conditions, carbon vanes can last anywhere from several thousand to tens of thousands of hours.

2. Can carbon vanes be used in oil-lubricated pumps?

Yes, carbon vanes can be used in oil-lubricated pumps. However, they are most commonly associated with oil-less or dry-running pumps due to their self-lubricating properties.

3. What are the signs that carbon vanes need to be replaced?

Signs of worn carbon vanes include a decrease in vacuum performance, increased noise or vibration, and visible wear or damage to the vanes themselves.

4. Are carbon vanes expensive?

The cost of carbon vanes varies depending on the size, material, and manufacturer. While they may be more expensive than some other vane materials, their long lifespan and performance benefits often make them a cost-effective choice in the long run.

5. Can I replace the vanes in my vacuum pump myself?

Replacing vanes in a vacuum pump is a task that can often be performed by users with some mechanical aptitude. However, it’s essential to follow the manufacturer’s instructions carefully and use the correct replacement parts.

6. How does the use of carbon vanes contribute to environmental protection?

Carbon vanes contribute to environmental protection by enabling the use of oil-less vacuum pumps, which eliminate the risk of oil contamination and reduce the need for oil disposal. This is particularly important in environmentally sensitive applications.

Conclusion

What are the uses of carbon vanes? They are diverse and essential, spanning a multitude of industries and applications. Carbon vanes are integral components in vacuum pumps and compressors, providing a reliable, efficient, and often oil-free solution for generating vacuum and moving gases. Their unique properties, including self-lubrication, high-temperature resistance, and chemical inertness, make them ideal for demanding environments. As technology continues to advance, we can expect further innovations in carbon vane materials and designs, expanding their capabilities and solidifying their role in modern industrial processes. The versatile applications of carbon vanes are a testament to their importance in various sectors. By understanding the function and benefits of carbon vanes, engineers and technicians can make informed decisions about pump selection, maintenance, and optimization, ensuring the continued success of their operations. This knowledge not only enhances operational efficiency but also promotes a deeper appreciation for the intricate engineering that powers our industrial world. The carbon vane is a small but mighty component in the world of vacuum pumps. If you’re working with a pump that uses a vane, it’s likely a carbon vane.