What Are Refrigeration Vacuum Pump Stages and What Do They Mean?

When dealing with refrigeration systems, one of the most important components ensuring the system operates efficiently is the vacuum pump. The vacuum pump is a vital tool used to remove air, moisture, and non-condensable gases from the refrigeration system, creating the perfect environment for proper cooling and heat transfer. But when it comes to vacuum pumps, you might hear the term “stages” – specifically single-stage and two-stage pumps. In this article, we will delve into what refrigeration vacuum pump stages mean and how they affect the performance of your refrigeration system.

What is a Refrigeration Vacuum Pump?

Before we dive into the different stages, it is important to understand what a vacuum pump is in the context of refrigeration. A vacuum pump is used in refrigeration to evacuate a system by removing all the air and moisture. This creates a deep vacuum, which helps in keeping the system free of contaminants like moisture, which can potentially harm refrigeration units.

Vacuum pumps in refrigeration work by reducing the pressure inside the system to below atmospheric pressure, allowing for the proper flow and transfer of the refrigerant. They essentially pull all the air and impurities out, ensuring a clean and efficient refrigeration cycle.

Key Components of a refrigeration vacuum pump include:

- Motor: Provides the power needed to drive the pump.

- Oil Reservoir: Maintains lubrication and helps in creating an effective seal.

- Inlet and Outlet Ports: Allow the connection to the system for evacuation.

Vacuum pumps are crucial for the longevity and effectiveness of refrigeration systems, and understanding their operation is key for technicians and enthusiasts alike.

Internal Link: If you need high-quality vanes for your vacuum pump, check out our Carbon Vanes Collection.

Understanding Single-Stage and Two-Stage Vacuum Pumps

Single-Stage Vacuum Pumps

A single-stage vacuum pump has just one set of rotors and vanes, meaning it has one compression cycle. During operation, the pump pulls in air or gas from the system, compresses it, and exhausts it in one continuous process. Here are some characteristics of single-stage pumps:

- Simplicity: The single-stage pump is simpler in design and has fewer moving parts, which makes it reliable and easy to maintain.

- Lower Cost: Due to its straightforward design, single-stage pumps tend to be more affordable compared to their two-stage counterparts.

- Sufficient for Shallow Vacuums: Single-stage pumps can usually reach a vacuum level of 75 microns, which is sufficient for many general-purpose refrigeration systems.

Advantages of Single-Stage Pumps:

- Cost-effective: A great option for basic refrigeration tasks without needing a deep vacuum.

- Low Maintenance: Fewer parts mean fewer chances of something going wrong.

However, single-stage pumps might not be ideal for systems that require deeper vacuums because their design limits their ability to achieve lower pressures.

Two-Stage Vacuum Pumps

A two-stage vacuum pump, as the name implies, consists of two sets of rotors and vanes. Essentially, it pulls air from the system twice, providing better evacuation and deeper vacuum levels. The process involves the first stage compressing the air and passing it to the second stage for further compression, leading to lower ultimate pressures.

- Deeper Vacuum Levels: Two-stage pumps can achieve much lower pressures, typically around 15 microns or less.

- Efficient Moisture Removal: They are ideal for systems that need thorough evacuation, especially when removing moisture and non-condensable gases from the system.

- Higher Pumping Speed: Two-stage pumps can handle a larger volume, making them suitable for commercial and industrial refrigeration systems.

Advantages of Two-Stage Pumps:

- Achieve Deeper Vacuums: Essential for certain refrigeration applications like industrial systems that require a high degree of evacuation.

- Improved Efficiency: More effective at removing moisture and contaminants, which can enhance system reliability.

“Two-stage pumps are preferred for refrigeration systems requiring high performance and thorough evacuation.”

Single-Stage vs. Two-Stage: Key Differences

| Feature | Single-Stage Pump | Two-Stage Pump |

|---|---|---|

| Vacuum Depth | 75 microns | 15 microns or lower |

| Cost | Lower | Higher |

| Design Complexity | Simple | More complex with two compression stages |

| Applications | General refrigeration systems | Industrial, large, and deep vacuum applications |

| Moisture Removal | Less effective | Highly effective |

Single-stage pumps are great for simpler tasks, while two-stage pumps are essential when you require high levels of vacuum for specialized refrigeration processes. They provide enhanced capabilities at a higher cost and complexity, making them better suited for industrial applications or those demanding a deep vacuum.

Why Does Stage Matter in Refrigeration Vacuum Pumps?

The stage of a vacuum pump plays a significant role in the vacuum depth that can be achieved. The depth of vacuum directly affects the efficiency of a refrigeration system. Here’s why the number of stages matters:

- Moisture Removal: Moisture inside a refrigeration system can cause several issues, including corrosion, freezing, and reduced system efficiency. Two-stage pumps are much better at removing moisture due to their capability to achieve a deeper vacuum.

- Non-Condensable Gases: Non-condensable gases are detrimental to refrigeration systems as they take up space that should be occupied by refrigerant, thus reducing cooling efficiency. Two-stage pumps are more efficient at removing these gases.

- System Size: For smaller refrigeration systems, a single-stage pump is usually sufficient, while larger systems or those requiring a more meticulous evacuation process benefit from a two-stage pump.

The choice between single-stage and two-stage pumps should always consider the application requirements of the refrigeration system in question.

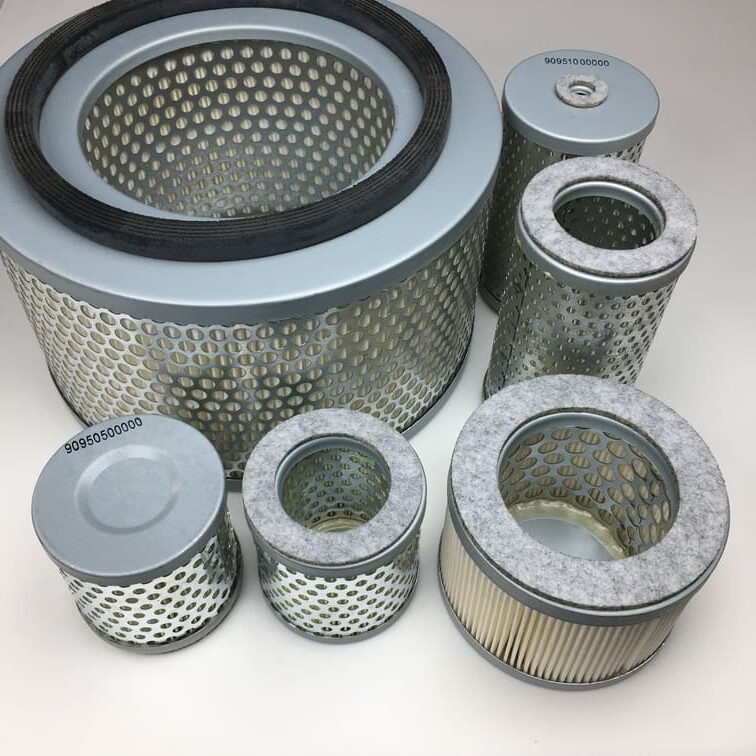

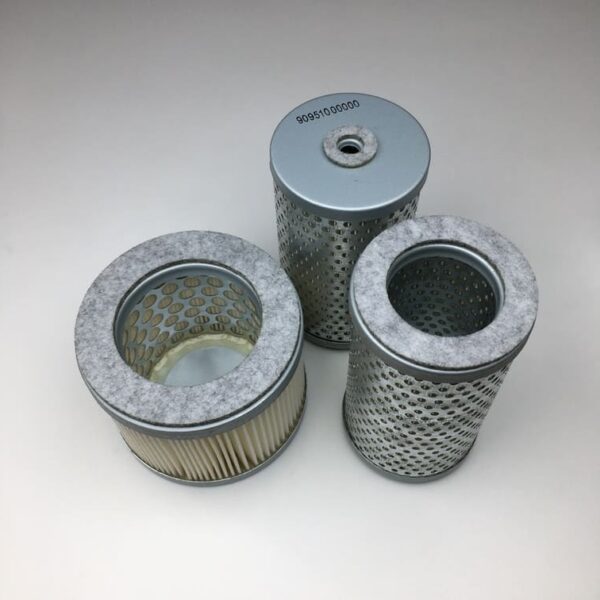

Internal Link: Find quality air filters to keep your refrigeration system efficient at our Becker Air Filters.

How to Choose Between Single-Stage and Two-Stage Vacuum Pumps

Application Requirements

Consider the type of application. If you are working on commercial or industrial refrigeration systems, the depth of vacuum required will likely be greater, necessitating a two-stage pump.

- Household Refrigeration Systems: A single-stage pump is usually enough as the vacuum requirements are not as stringent.

- Commercial Refrigeration and HVAC: For larger, commercial-grade systems, a two-stage vacuum pump is recommended.

Desired Vacuum Levels

If your system requires a deep vacuum, then it is necessary to choose a two-stage pump. Single-stage pumps cannot provide the deep levels of vacuum needed for some refrigeration processes, which could lead to problems such as inefficient cooling or the build-up of moisture.

Budget Constraints

Two-stage pumps, while more effective, are also more costly. A single-stage pump can be an adequate solution for those on a tight budget who do not need to achieve a deep vacuum.

- Maintenance Costs: Two-stage pumps may also require more maintenance due to their complexity, so consider these costs when making a decision.

The Role of Gas Ballast Valve in Vacuum Pumps

Many vacuum pumps come equipped with a gas ballast valve, which plays a crucial role in the removal of moisture during the evacuation process. This valve allows a controlled amount of air into the pump during compression, which helps prevent water vapor from condensing within the pump oil, thereby maintaining pump efficiency.

Benefits of Using Gas Ballast

- Reduced Oil Contamination: Prevents moisture from contaminating the pump oil, extending its lifespan.

- Improved Performance: Ensures that the pump can maintain efficient operation even when there is a higher moisture content in the system.

For vacuum pumps used in refrigeration, especially two-stage systems, the gas ballast valve becomes an essential feature that supports extended usage and maintains optimal performance.

FAQs

1. What is the difference between single-stage and two-stage vacuum pumps?

The primary difference lies in their ability to achieve vacuum levels. Single-stage pumps use one compression cycle, while two-stage pumps compress air twice, allowing them to achieve much deeper vacuums.

2. Which vacuum pump should I use for my refrigeration system?

For most household refrigeration systems, a single-stage pump is sufficient. For commercial or industrial refrigeration systems requiring a deep vacuum, a two-stage pump is recommended.

3. How does a gas ballast valve benefit a vacuum pump?

A gas ballast valve helps to prevent moisture from condensing within the pump oil, which keeps the oil clean and maintains the efficiency of the pump.

4. Why is achieving a deep vacuum important in refrigeration systems?

A deep vacuum is crucial for removing moisture and non-condensable gases from the system. These contaminants can reduce the efficiency and reliability of the refrigeration cycle.

5. Are two-stage vacuum pumps worth the extra cost?

Yes, if your application requires a deep vacuum or if you are working with large commercial systems, the additional cost of a two-stage pump is justified by its increased efficiency and effectiveness.

Conclusion

Understanding the difference between single-stage and two-stage vacuum pumps is vital when working with refrigeration systems. Choosing the correct pump can significantly impact the system’s efficiency, reliability, and lifespan. Single-stage pumps are suitable for basic refrigeration needs, while two-stage pumps are ideal for more demanding applications requiring deep vacuum levels. When in doubt, always consider the type of system you are servicing, your budget, and the level of vacuum required. Investing in the right vacuum pump ensures your refrigeration system remains free of contaminants, thus maximizing its cooling efficiency and overall performance.

For a wide range of vacuum pump parts and accessories, visit vacuumpumppart.com. Our collection includes everything from carbon vanes to filters that keep your vacuum system running at peak performance.