Is Refrigerant Recovery Pump Good for Evacuation at Vacuum Standing Test?

In the realm of HVAC and refrigeration, the evacuation process is crucial for ensuring optimal performance. It involves removing all contaminants, moisture, and air from the system before adding the refrigerant. One question that often arises is whether a refrigerant recovery pump can effectively perform an evacuation at vacuum standing test. In this comprehensive guide, we’ll delve into the use of refrigerant recovery pumps, their role in vacuum tests, and how to properly evaluate their suitability.

Understanding these processes will help you determine if a refrigerant recovery pump is suitable for the job, or whether you need to opt for a more dedicated vacuum pump.

What is a Refrigerant Recovery Pump?

Definition and Purpose

A refrigerant recovery pump is a device used to remove refrigerant from HVAC systems and store it in a recovery tank. This process is essential for maintenance, system decommissioning, and retrofitting. The purpose of a recovery pump is to prevent refrigerants from leaking into the atmosphere, which could cause environmental damage.

- Recovery Mode: Extracts refrigerant from the system.

- Purging Mode: Releases air and non-condensable gases.

| Component | Function |

|---|---|

| Compressor | Compresses refrigerant vapors |

| Condenser | Cools down refrigerant |

| Recovery Tank | Stores refrigerant safely |

Can It Perform an Evacuation?

While refrigerant recovery pumps are effective at removing refrigerant, they are not designed for evacuating the entire system of air and moisture. The vacuum required for complete evacuation is much deeper than what a recovery pump can achieve. Typically, a recovery pump can only pull down to around 500-1000 microns, which is insufficient for the thorough evacuation necessary in HVAC systems.

Important Note: A refrigerant recovery pump is not the ideal choice for performing vacuum standing tests or complete system evacuation.

What is a Vacuum Standing Test?

Definition and Importance

A vacuum standing test is used to determine if an HVAC system is completely free of leaks before charging it with refrigerant. During this test, the system is evacuated to a specific vacuum level, and the pressure is monitored for a set period.

- Purpose: To ensure that no leaks are present and that all moisture has been removed.

- Ideal Vacuum Level: Typically between 200-500 microns.

The standing test helps in identifying leaks or the presence of moisture, which can lead to issues such as reduced efficiency, compressor failure, or corrosion.

Procedure for Conducting a Vacuum Standing Test

- Connect a Vacuum Pump: Attach a high-quality vacuum pump to the system’s service ports.

- Pull a Deep Vacuum: Allow the pump to evacuate the system until a target vacuum level of 500 microns or lower is reached.

- Monitor the Vacuum Gauge: Shut off the vacuum pump and monitor the pressure over time. Any rise in pressure indicates a possible leak or moisture presence.

Tip: Use a digital micron gauge for accurate readings.

Differences Between Recovery Pumps and Vacuum Pumps

To understand why a recovery pump might not be ideal for evacuation, it’s essential to compare it to a vacuum pump.

Key Differences

| Feature | Recovery Pump | Vacuum Pump |

|---|---|---|

| Purpose | Removes refrigerant | Removes air and moisture |

| Pressure Levels | Moderate (above 1000 microns) | Deep Vacuum (< 500 microns) |

| Efficiency | Designed for refrigerant safety | Designed for deep evacuation |

Why Vacuum Pumps are Necessary for Evacuation

A vacuum pump is designed to remove all gases, including non-condensable ones, and reach much deeper vacuum levels. This is necessary for the system to be moisture-free and prepared for charging with refrigerant.

- Dual-Stage Pumps: These are preferred for achieving deeper vacuums.

- Ultimate Vacuum: Most vacuum pumps can reach down to 50-100 microns, which is far beyond the capabilities of recovery pumps.

Can a Recovery Pump be Used for Vacuum Standing Test?

The Practical Limitations

Refrigerant recovery pumps are not built to reach the depth required for a proper vacuum. While they are excellent for removing refrigerant from the system, they cannot achieve the ultimate low pressures needed for thorough moisture evacuation.

Key Challenges:

- Vacuum Depth: Recovery pumps cannot achieve the sub-500 micron levels needed for moisture and non-condensable removal.

- Continuous Pressure Rise: Systems evacuated with recovery pumps often fail the vacuum standing test because they are not properly dried out.

In a vacuum standing test, if you use a recovery pump, the pressure will tend to rise, which may lead you to believe there is a leak, while in fact, it’s just residual moisture.

How to Use a Vacuum Pump for Evacuation and Standing Test

Step-by-Step Process

- Prepare the System: Ensure that all service ports and connections are secure.

- Attach a High-Quality Vacuum Pump: Connect the vacuum pump and open the service valves.

- Pull a Deep Vacuum: Let the vacuum pump run until the system pressure reaches 500 microns.

- Close the Valves and Conduct a Standing Test: Monitor the pressure. If it holds steady below 500 microns, your system is free of leaks and moisture.

Using Vacuum Gauges for Accuracy

A vacuum gauge measures the pressure during evacuation and the standing test. For best results:

- Use a digital gauge that can read down to the micron level.

- Ensure the gauge is calibrated for accuracy.

Tip: If the vacuum level starts to increase during the standing test, it may indicate moisture still in the system or a minor leak.

Advantages of Using a Vacuum Pump for Evacuation

Efficiency in Removing Moisture

A vacuum pump can effectively remove even trace amounts of moisture, ensuring the system is dry before adding refrigerant. Moisture left in the system can combine with refrigerant to create acids, which can damage the compressor.

Improved System Performance

By achieving a proper deep vacuum, your HVAC system will operate at peak efficiency. Reduced moisture and non-condensable gases mean fewer chances of freezing, compressor wear, and energy wastage.

Comparison Table

| Pump Type | Application | Micron Level Achievable |

|---|---|---|

| Refrigerant Recovery | Remove refrigerant only | 1000 microns or higher |

| Vacuum Pump | Complete system evacuation | 500 microns or lower |

Common Mistakes to Avoid When Evacuating an HVAC System

Mistake 1: Using the Wrong Pump

Many HVAC technicians use a refrigerant recovery pump for evacuation, not realizing that it cannot achieve the necessary deep vacuum. Always use a vacuum pump specifically designed for evacuating air and moisture.

Mistake 2: Not Using a Vacuum Gauge

Skipping the vacuum gauge means you’re essentially working in the dark. A gauge is the only way to verify that the system has reached the required vacuum level.

Mistake 3: Failing to Replace Oil in the Vacuum Pump

The oil in a vacuum pump acts as a seal and lubricant. Old, contaminated oil reduces the pump’s efficiency and its ability to pull a deep vacuum. Regular oil changes are essential for maintaining the pump’s performance.

Related Resources and Vacuum Parts

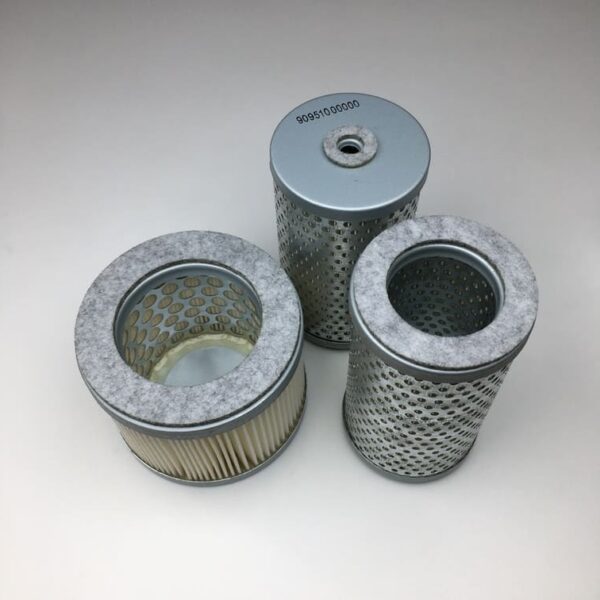

To ensure you have the right equipment for evacuation and standing tests, consider high-quality vacuum parts like the Becker Air Filter, which helps maintain clean airflow. Check out:

- Becker Air Filter replaces Becker 909540 for better efficiency.

- Vacuum Pump Spare Parts to find original filters and vanes to keep your vacuum pump in top condition.

Frequently Asked Questions

1. Can I use a refrigerant recovery pump to evacuate an HVAC system?

No, a refrigerant recovery pump cannot achieve the deep vacuum levels necessary for evacuation. It is designed only for refrigerant recovery, not for removing air or moisture.

2. What is the ideal vacuum level for an HVAC evacuation?

The ideal vacuum level is typically 500 microns or lower. This level ensures that all moisture and non-condensables are removed from the system.

3. How long should I keep the vacuum pump running during evacuation?

The time required depends on the size of the system and the capacity of your vacuum pump. For most systems, it takes 15-30 minutes to achieve an acceptable vacuum level, but some larger systems may take longer.

4. Why is my vacuum level not holding during the standing test?

If the vacuum level rises during the standing test, it could mean there is a leak in the system or moisture that has not been completely removed.

5. What kind of oil should I use in my vacuum pump?

Always use vacuum pump oil specifically designed for your model. It ensures proper lubrication and an effective vacuum seal.

Conclusion

Using a refrigerant recovery pump for evacuation during a vacuum standing test is not recommended. While it is perfect for removing refrigerants from HVAC systems, it cannot achieve the deep vacuum necessary for a successful evacuation. Instead, a dedicated vacuum pump should be used to pull down to 500 microns or lower, ensuring the removal of all moisture and air. This leads to better system performance, longer equipment life, and fewer issues down the road.

For more tips, tools, and high-quality parts to keep your HVAC and refrigeration systems running smoothly, check out Vacuum Pump Spare Parts. Make sure your evacuation process is flawless, and your equipment is up to the task every time.