How to Use a Vacuum Pump for Wine Transfer

Transferring wine from one container to another is an essential step in winemaking. Using a vacuum pump for wine transfer has become increasingly popular among both amateur and professional winemakers. This method helps reduce oxidation, maintain the quality of the wine, and simplifies the process compared to traditional methods. In this comprehensive guide, we will explore the steps involved in using a vacuum pump for wine transfer, the necessary equipment, and the benefits of adopting this technique. Whether you’re a seasoned winemaker or a beginner exploring new methods, this guide will provide you with all the essential knowledge.

Understanding Vacuum Wine Transfer

Vacuum wine transfer is a method of moving wine from one vessel to another using negative pressure generated by a vacuum pump. Unlike gravity or siphoning methods, which often introduce oxygen into the wine, vacuum transfer keeps the exposure to air minimal, thereby preserving the wine’s integrity.

Why Use a Vacuum Pump?

- Minimize Oxidation: One of the biggest threats to wine quality during transfer is oxidation. Using a vacuum pump helps reduce air exposure, ensuring your wine retains its intended flavor and aroma.

- Convenience: Vacuum pumps are easy to use and can speed up the process significantly. No need to lift heavy carboys or use gravity setups.

- Versatility: The same setup can be used for other tasks like degassing wine, transferring juice, and racking to a receiving carboy.

“Vacuum wine transfer is perfect for anyone looking to improve the quality of their home-brewed wines. It is simple, effective, and helps maintain the wine’s unique flavors.” – Senior Member of Wine Making Forum

Equipment Needed for Vacuum Wine Transfer

Before starting the wine transfer, it is important to gather all the necessary equipment. Below is a list of items you will need:

| Equipment | Description |

|---|---|

| Vacuum Pump | Creates the negative pressure needed for transfer. |

| Racking Cane | A tube that moves wine from the bottom of the carboy. |

| Receiving Carboy | The container into which the wine is transferred. |

| Silicone Tubing | Connects components and creates a sealed transfer. |

| Vacuum Hose Adapter | Allows for easy connection between pump and tubing. |

Pro Tip: Make sure to use stainless steel racking canes and food-safe silicone tubing to ensure your wine stays uncontaminated throughout the process.

Step-by-Step Guide to Using a Vacuum Pump for Wine Transfer

Step 1: Set Up the System

- Attach the Vacuum Pump: Begin by attaching the vacuum pump to a power source. Ensure that the vacuum pump is securely placed on a stable surface to prevent any movement during use.

- Connect Tubing: Attach the silicone tubing to the vacuum pump. One end of the tubing should be connected to the vacuum pump, while the other end is connected to the racking cane.

- Insert the Racking Cane: Place the racking cane into the original carboy containing the wine. Ensure that it reaches near the bottom of the container without disturbing any sediment.

Note: Always sanitize all equipment before using it to ensure there is no contamination. Wine is susceptible to bacteria, and cleanliness is paramount.

Step 2: Create a Vacuum

- Turn On the Vacuum Pump: Switch on the vacuum pump to start creating a vacuum inside the receiving carboy. This negative pressure will gently pull the wine from the original container to the receiving carboy.

- Monitor the Process: You will notice the wine starting to flow through the racking cane and tubing. The vacuum pump’s negative pressure will help transfer the wine smoothly without the need for siphoning or lifting.

Key Tip: Avoid high vacuum pressure to prevent agitation of the wine, which could lead to oxidation. A slow and steady flow rate is preferable.

Step 3: Completing the Transfer

- Watch the Wine Level: Keep an eye on the wine level in the receiving carboy to prevent overflow. Stop the pump when the wine reaches the desired level.

- Release the Vacuum: After the transfer is complete, carefully release the vacuum pressure. This step ensures that no additional air is sucked into the receiving carboy, which could affect the wine quality.

- Seal the Carboy: Once the transfer is complete, immediately seal the receiving carboy with an airlock or bung to protect the wine from air exposure.

Benefits of Using a Vacuum Pump for Wine Transfer

1. Reduced Oxidation Risk

The primary benefit of using a vacuum pump is the significant reduction in oxidation. Wine is very sensitive to oxygen, and even slight exposure during racking can alter its taste and aroma. A vacuum pump helps create a controlled environment with minimal oxygen contact.

2. Ease of Use

With traditional methods, transferring wine can involve lifting heavy glass carboys and managing complex siphons. A vacuum pump allows you to rack your wine with minimal effort, making the process more accessible and reducing the risk of injury.

- No Heavy Lifting: Once everything is set up, you no longer need to lift and hold heavy carboys.

- Smooth Flow: The flow is controlled and steady, reducing the likelihood of spillage or splashing.

3. Versatile Functionality

Vacuum pumps can also be used for other processes in winemaking, such as vacuum racking, degassing, and moving other liquids. This versatility makes the vacuum pump a great tool for every winemaker’s collection.

Common Issues and Troubleshooting Tips

1. Wine Is Not Flowing Properly

If you notice that the wine is not flowing smoothly or is not flowing at all, it could be due to a number of reasons:

- Check the Tubing: Ensure that all tubing connections are tight and that there are no air leaks.

- Inspect the Pump: The vacuum pump should be functioning correctly. Listen for unusual noises that may indicate a problem.

- Racking Cane Placement: Ensure that the racking cane is properly positioned, avoiding any sediment at the bottom of the carboy.

2. Foaming During Transfer

Foaming can indicate that the vacuum pressure is too high. To avoid this issue:

- Reduce the Pump Speed: Lower the pump speed or reduce the vacuum to create a gentler transfer.

- Adjust the Cane Position: Make sure the racking cane is not disturbing the sediment, which can cause excessive foaming.

3. Air Bubbles in the Tubing

Seeing air bubbles in the tubing is often a sign that there is a loose connection somewhere in the system.

- Tighten Connections: Double-check that all fittings are secure.

- Check for Cracks: Inspect the tubing for any damage that could cause air leaks.

“Maintaining your vacuum pump setup properly is essential for a successful wine transfer. Ensure that all parts are clean and functioning well.” – Latest Winemaker81 from Wine Making Forum

Internal Links for Further Guidance

To better understand the types of pumps and components used in wine vacuum transfer, you may refer to the following resources:

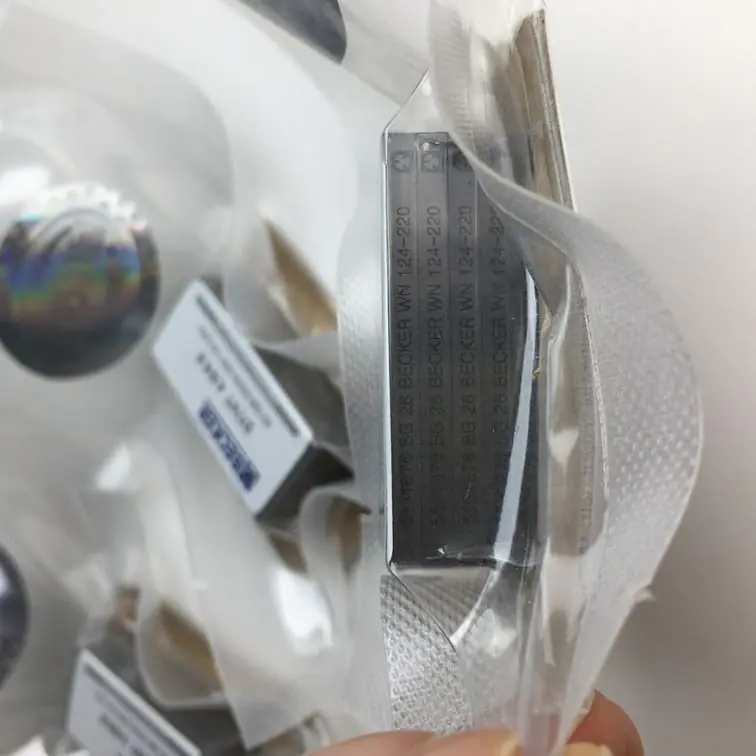

- Vacuum Pump Spare Parts – Learn about maintaining and replacing parts for your vacuum pump to ensure optimal performance.

- Becker Air Filters for Wine Making – Check how Becker air filters can be integrated into your wine vacuum system to maintain cleanliness.

Frequently Asked Questions

1. Can I use a vacuum pump for transferring both red and white wine?

Yes, vacuum pumps are suitable for transferring both red and white wines. They help reduce oxidation for both types, preserving their flavors and aromas.

2. How much vacuum pressure should be used during wine transfer?

The vacuum pressure should be kept low to moderate to avoid agitating the wine. Ideally, keep the vacuum between 10-15 inches of mercury (Hg).

3. Is it necessary to sanitize the vacuum pump?

Absolutely. All equipment, including the vacuum pump, should be thoroughly sanitized before use to prevent contamination that could spoil your wine.

4. What type of tubing is best for vacuum wine transfer?

It is best to use food-grade silicone tubing. This type of tubing is flexible, easy to work with, and safe for use with beverages.

5. Can I use a vacuum pump to degas wine?

Yes, vacuum pumps can also be used to effectively degas wine by creating a negative pressure environment, helping to remove carbon dioxide from the liquid.

Conclusion

Using a vacuum pump for wine transfer can greatly enhance the quality of your homemade wine by minimizing oxidation and simplifying the transfer process. By adopting this method, you can ensure your wine retains its intended flavors and aromas, without the risk of contamination or exposure to excess oxygen. Whether you are just beginning your winemaking journey or are a seasoned veteran, investing in a vacuum pump will make your process more efficient and enjoyable.

For more information on vacuum pumps, accessories, and maintenance products, visit VacuumPumpPart.com. Keeping your equipment well-maintained is key to producing exceptional wine, batch after batch.