How to Use a Vacuum Pump for BHO

Butane Hash Oil (BHO) extraction is one of the most popular methods for obtaining highly concentrated cannabis extracts. However, after the initial extraction, there’s an essential step known as vacuum purging that ensures a safe and pure end product. In this article, we will explore how to use a vacuum pump for BHO purging, the necessary equipment, and best practices to achieve an optimal final product.

Understanding BHO Extraction and Purging

Before diving into the details of how to use a vacuum pump for BHO, it’s helpful to understand why vacuum purging is important. Butane extraction leaves behind residual solvents that can be harmful if not properly removed. The process of vacuum purging uses reduced air pressure to help remove these solvents at lower temperatures, resulting in a cleaner and safer product.

In a typical setup, the extract is placed in a vacuum chamber under reduced pressure, which allows the butane to evaporate away without subjecting the extract to high heat, thus preserving the terpenes and other valuable compounds.

Equipment Required for Vacuum Purging BHO

To properly purge BHO, you’ll need a set of specific tools and materials. Below are the basic pieces of equipment required:

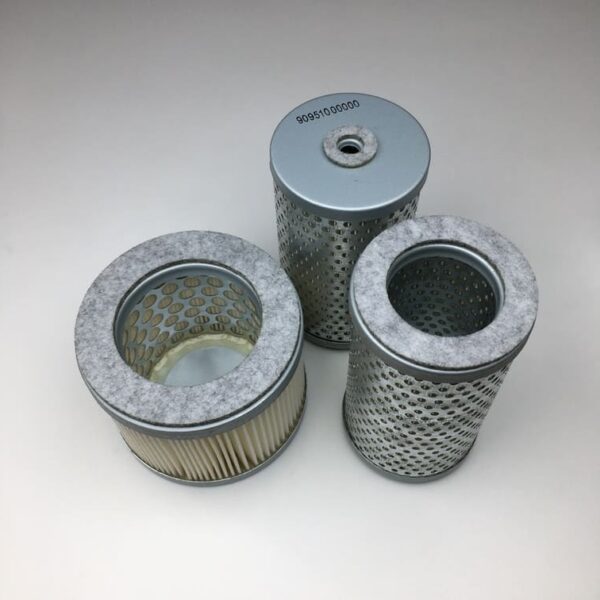

- Vacuum Pump: A rotary vane pump is commonly used for vacuum purging. These pumps create the necessary vacuum to pull out residual butane from the oil.

- Vacuum Chamber: This is an airtight chamber where the BHO is placed. It’s important that this chamber is compatible with vacuum pressures and has a reliable seal.

- Heat Source: Often, a heating pad or vacuum oven is used to gently warm the oil during purging, helping butane to release more easily.

- Parchment Paper: The extract is placed on parchment paper inside the vacuum chamber to keep it from sticking to the surface of the chamber.

Internal Link: For a detailed guide on the types of vacuum pumps available, visit our Vacuum Pump Spare Parts Guide.

Choosing the Right Vacuum Pump

When selecting a vacuum pump for purging BHO, you have a few options. Typically, a two-stage rotary vane pump is preferred because it can reach deeper vacuum levels, which helps in efficiently purging residual butane. Let’s take a look at some types of vacuum pumps suitable for purging BHO:

- Single-Stage Rotary Vane Pumps:

- Advantages: Cheaper and easier to maintain.

- Disadvantages: Cannot achieve as deep a vacuum as two-stage pumps, which may leave some residual butane.

- Two-Stage Rotary Vane Pumps:

- Advantages: Capable of achieving a deeper vacuum, which is ideal for efficient solvent removal.

- Disadvantages: More expensive and requires more maintenance.

Setup and Operation of a Vacuum Pump for BHO

The process of using a vacuum pump to purge BHO involves a few critical steps:

- Prepare the Extract: Place your BHO extract on parchment paper. This allows for easy removal after purging and prevents sticking.

- Positioning in the Vacuum Chamber: Place the parchment paper inside the vacuum chamber. Make sure the oil is spread out evenly, as a larger surface area helps in effective solvent removal.

- Applying Heat: Use a heating pad or oven to gently warm the vacuum chamber to around 85-100°F (29-38°C). The key is to keep the temperature low enough to preserve the integrity of the cannabinoids and terpenes, while also helping the butane evaporate.

- Turn On the Vacuum Pump: Connect the vacuum pump to the chamber and turn it on. Gradually increase the vacuum pressure. You may notice the BHO starting to bubble as the butane leaves the mixture. These bubbles are a sign that residual solvents are being purged.

Internal Link: To enhance your vacuum purging setup, consider using our Becker Air Filters to keep your vacuum pump functioning effectively.

Monitoring the Purging Process

Purging BHO is not an exact science, and it requires careful attention to achieve optimal results. Here are a few factors to keep in mind:

- Time: The amount of time required for purging depends on the size of the batch and the vacuum level achieved. Typically, purging can take anywhere from a few hours to over 24 hours.

- Pressure Level: Most experts recommend maintaining a vacuum level of -29.5 inches of mercury (Hg). This ensures enough pressure reduction to pull out most of the solvents.

- Bubbling: During the purging process, the oil will bubble as butane is released. The purging process should continue until bubbling slows down and eventually stops, indicating that the majority of the solvent has been removed.

Note: Over-purging at high temperatures can degrade the product, so it is vital to monitor both temperature and time.

Best Practices for Vacuum Purging BHO

1. Use Food-Grade Butane

For safe BHO extraction, always use food-grade butane. Lower-quality solvents can introduce contaminants that make the purging process more challenging and result in a less pure product.

2. Maintain Optimal Temperatures

The ideal temperature range for purging BHO is between 85-100°F. Temperatures higher than this can lead to degradation of cannabinoids and terpenes, which impacts the quality of the final product.

3. Avoid Over-Purging

While ensuring complete removal of butane is important, over-purging can lead to the degradation of valuable compounds. Maintaining the right balance of time and temperature is key to preserving the quality of the extract.

Common Challenges and Solutions

1. Vacuum Pump Maintenance

Vacuum pumps require regular maintenance to perform at their best. Oil levels should be checked frequently, and oil should be changed as per manufacturer recommendations to prevent contamination.

Internal Link: Regularly replace vacuum pump components with our Becker Vacuum Vanes to maintain efficiency.

2. Achieving a Deep Enough Vacuum

If you are struggling to achieve a deep enough vacuum, the issue could be with the seals on your vacuum chamber or a leak in the system. Always inspect the rubber gaskets on the chamber and make sure all fittings are properly tightened.

FAQs

1. How long should I purge BHO with a vacuum pump?

Purging times can vary depending on the volume of extract, but typically it takes between 8-24 hours. The goal is to purge until there is minimal to no bubbling in the extract.

2. What vacuum level is needed to purge BHO?

A vacuum level of around -29.5 inches of mercury (Hg) is generally recommended for purging BHO efficiently.

3. What happens if I don’t purge my BHO properly?

If BHO is not properly purged, it can contain residual solvents, which are harmful to consume. Proper purging ensures a safer and higher-quality end product.

4. Can I use a single-stage pump for BHO purging?

Yes, you can use a single-stage pump, but it may not achieve as deep a vacuum as a two-stage pump, resulting in a less effective purge.

5. Do I need a vacuum oven for BHO purging?

A vacuum oven is not mandatory but can be very helpful. It allows for consistent heat and vacuum pressure, which improves the quality and consistency of the final product.

6. What temperature should I maintain during vacuum purging?

Maintain a temperature range of 85-100°F to effectively purge without degrading the extract.

Conclusion

Vacuum purging is an essential step in the BHO extraction process, ensuring that harmful solvents are removed and leaving you with a clean and safe final product. By using a reliable vacuum pump and following best practices for temperature and pressure, you can achieve high-quality extracts. Remember, selecting the right pump, maintaining proper temperatures, and ensuring regular maintenance are the keys to successful BHO purging.

The right equipment and methods make all the difference in achieving a pure, flavorful, and safe BHO product. If you’re interested in more detailed guides or want to find parts and accessories for your vacuum pump setup, check out our selection at VacuumPumpPart.com.