How to Turn a Ball Pump Into a Vacuum Pump

Vacuum pumps are incredibly useful tools, from science experiments to small-scale industrial applications. But did you know that you can make a simple vacuum pump out of an everyday ball pump? Yes, it’s possible, and in this guide, we’ll explore how you can transform a ball pump into a functional vacuum pump that can create vacuum pressure. Not only is this an intriguing DIY project, but it’s also an affordable way to learn more about vacuum systems.

Let’s dive in to see how to transform your ball pump, how vacuum pumps work, and what you need to know to get started.

Understanding How a Vacuum Pump Works

To understand how to modify a ball pump into a vacuum pump, it helps to first know a little bit about how vacuum pumps work. Essentially, a vacuum pump is a device that removes gas molecules from a sealed volume, creating a partial vacuum. These pumps are widely used in numerous industries for processes that require pressure control, such as medical equipment, automotive work, and vacuum sealing.

The key principle of a vacuum pump is to draw air out of a closed container, reducing the internal pressure. A ball pump, when reversed, can accomplish this process to some extent. This is a great entry-level project for understanding the mechanics of creating vacuum.

How Does a Ball Pump Work?

A ball pump is designed to move air by compressing it, which inflates items like basketballs or soccer balls. It has a simple one-way valve that allows air to move in one direction only. By modifying this mechanism, the pump can instead pull air out, thus acting as a vacuum pump. This setup can be useful for simple tasks, such as creating a vacuum to demonstrate pressure concepts, or in small DIY vacuum experiments.

Fun Fact: Did you know that the components of a vacuum pump can also be found in many common household items like refrigerator compressors? The simplicity of a ball pump makes it perfect for transformation into a vacuum pump.

Materials Required for Converting a Ball Pump

Before getting started, you’ll need a few materials to complete this project. These are common items that you may already have or can find at your local hardware store.

Essential Tools and Parts

- Ball pump: Any small hand-operated pump will do.

- Check valve: A check valve is necessary to allow air to be drawn out without coming back in.

- Tubing: Flexible plastic tubing that fits the outlet of the pump snugly.

- Plastic container: A sealed plastic container is needed to demonstrate the vacuum effect.

- Glue or adhesive sealant: To make airtight seals.

You can see a detailed description of similar parts on this Becker set of vanes. This set is commonly used in many vacuum pump applications.

Note: The flexibility of this setup allows you to reuse many parts that you might already have in your toolbox, making this an inexpensive project.

Step-by-Step Guide to Turn a Ball Pump Into a Vacuum Pump

Here’s how to convert your ball pump into a vacuum pump:

1. Prepare the Ball Pump

First, disassemble the ball pump and take a closer look at the valve mechanism. The valve in a ball pump usually allows air to move in one direction (inflow). We need to adjust this mechanism to allow the pump to pull air out of an external space rather than push it.

2. Install the Check Valve

Attach a check valve to the inlet of the pump. This component will control the airflow, making sure that the air can be drawn out of a container but not re-enter. The check valve is critical because it helps create an actual vacuum by preventing the air from leaking back into the container.

3. Connect the Tubing

Next, attach the tubing to the pump’s outlet. The tubing should be flexible and snugly fit onto the outlet to prevent any air leakage. You can use glue or adhesive sealant to ensure the connection is airtight. The tubing will act as the connecting line between the pump and the sealed container where you want to create the vacuum.

For more advanced users interested in further modifying their pump, check out the Becker Air Filter for high-quality filtration options that could help create a more efficient system.

4. Connect the Setup to a Sealed Container

Connect the other end of the tubing to the sealed plastic container. Ensure that the container is as airtight as possible. This will ensure that no external air enters the container, allowing you to successfully pull out the air and create a vacuum.

Tip: The better the seal, the higher quality of vacuum you can achieve. You can use epoxy or another type of strong adhesive to make a permanent airtight seal.

Applications and Limitations

Using a DIY vacuum pump like the one you’ve made from a ball pump is limited but still useful for small, hobby-level projects. Here are some practical uses and the inherent limitations:

Potential Applications

- Science Experiments: Simple vacuum experiments, such as showing how pressure affects boiling points or inflating a balloon in reverse.

- Small-Scale Vacuum Sealing: You can use it for vacuum sealing small plastic bags or items to keep them fresh.

- Testing Leakages: Use it to test for leakage in containers or small objects that need to be vacuum-sealed.

Useful Insight: If you are serious about vacuum systems, consider investing in an oil-sealed rotary vane vacuum pump like those discussed on our page about Becker vacuum pump spare parts. This pump type will deliver much stronger suction power and reliable performance.

Limitations of a DIY Ball Pump Vacuum Pump

While turning a ball pump into a vacuum pump is educational and satisfying, there are a few important limitations:

- Limited Vacuum Power: A ball pump cannot create the same level of vacuum as a professional vacuum pump. The pressure it can create is limited, making it suitable only for light, small-scale tasks.

- Durability: Since the pump is not originally designed to work as a vacuum pump, the wear and tear on internal components may limit its lifespan.

- Limited Material Compatibility: This pump may not be ideal for vacuuming liquids or other substances that might damage the check valve or tubing.

Enhancing the DIY Vacuum Pump Setup

There are several ways to enhance your new vacuum pump setup to get better performance.

1. Adding Filters

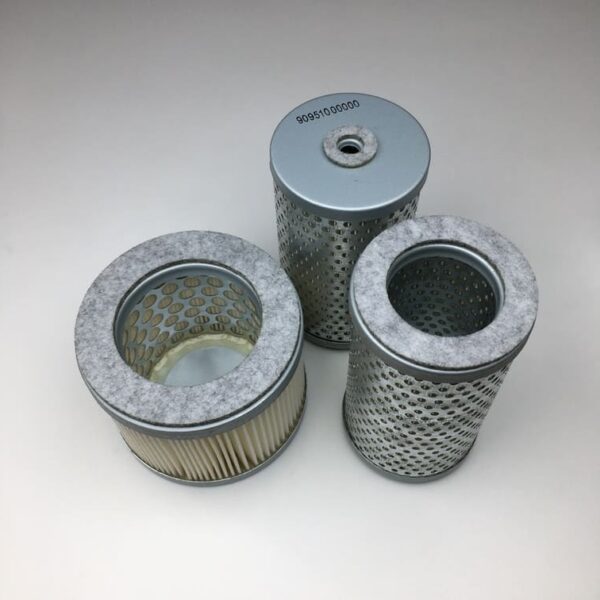

If you plan to use your vacuum pump frequently, adding a filter to the tubing will help protect the check valve and the pump itself from dust and debris. You can find quality filters like Mann-Filter Air Filters that are suitable for such tasks.

2. Upgrading the Check Valve

For a better seal and more reliable vacuum, consider using a high-quality metal check valve instead of a plastic one. This will make the vacuum pump more durable and more capable of maintaining a steady vacuum.

3. Using Stronger Adhesive

To improve vacuum efficiency, ensure that every connection in your setup is airtight. Using stronger adhesives like silicone or epoxy resin can help make these connections more durable and prevent air leaks during operation.

FAQs

1. What materials can be used for the tubing?

For this DIY vacuum pump, plastic tubing works best. It should fit tightly around the nozzle to prevent air leaks, ensuring better vacuum quality.

2. How powerful is a vacuum made with a ball pump?

The vacuum created with a ball pump is not as powerful as an industrial vacuum pump, but it can still create enough pressure difference for small applications like simple vacuum demonstrations or sealing.

3. Can I use this DIY vacuum pump for liquid extraction?

It’s not recommended to use this pump for extracting liquids, as the moisture could damage the check valve or internal parts of the pump. A professional vacuum pump would be more suitable for such tasks.

4. Is there a better alternative to a ball pump for a vacuum pump project?

Yes, a refrigerator compressor or an aquarium pump can make a more powerful DIY vacuum pump. They provide stronger suction and better pressure control.

5. Can this pump be used for vacuum bagging in woodworking?

No, the pressure levels achieved by a ball pump may not be sufficient for proper vacuum bagging in woodworking. A professional vacuum pump is ideal for such applications.

Conclusion

Transforming a ball pump into a vacuum pump is a fun and insightful project. It provides a unique opportunity to understand the principles of vacuum creation and pressure. While it won’t replace an industrial-grade vacuum pump, it can serve well for small experiments and educational purposes. If you need higher vacuum quality or power, consider purchasing professional-grade components or an oil-sealed rotary vane pump.

For those interested in vacuum technology or vacuum pump spare parts, vacuumpumppart.com has a wide selection to help you explore more advanced setups and achieve better results.