How to Test Mercedes Vacuum Pump: A Comprehensive Guide

Testing your Mercedes vacuum pump is a crucial part of maintaining your vehicle’s overall health. The vacuum pump plays an essential role in managing the proper functioning of several systems, including the brake booster, door locks, and HVAC systems. Understanding how to test the vacuum pump will help you identify potential problems, prevent breakdowns, and ensure your car remains in optimal condition.

In this guide, we’ll cover everything you need to know about testing a Mercedes vacuum pump: from the tools you’ll need, to the testing process, troubleshooting tips, and practical advice for maintaining your vacuum system.

What is a Vacuum Pump and Why is it Important?

A vacuum pump is a critical component in a Mercedes diesel or any modern car with a gasoline or diesel engine. Its primary role is to create a vacuum for systems like the brake booster, HVAC system, and door locks. Without a properly functioning vacuum pump, these systems can fail, leading to poor vehicle performance or even safety hazards.

In Mercedes vehicles, the vacuum pump also helps maintain vacuum reservoirs which serve as a buffer to supply consistent vacuum pressure. Problems in the vacuum pump or any related components can lead to difficulties such as brakes not feeling responsive, HVAC not functioning correctly, or central locking malfunctions.

The components related to the vacuum system include:

- Vacuum reservoir – Stores vacuum for consistent supply.

- Supply line – Connects the pump to other components.

- Check valves – Prevent vacuum leaks and allow directional flow.

- Metering valves – Help regulate the amount of vacuum sent to different components.

Common Symptoms of a Faulty Vacuum Pump

- Hard brake pedal: Reduced or lack of power brake assistance.

- HVAC system issues: Difficulty controlling air direction or temperature.

- Malfunctioning door locks: Central locking not working or working intermittently.

- Engine running poorly: Erratic idling or hesitation.

These symptoms indicate the need for prompt testing of the vacuum system.

Tools Required for Testing a Mercedes Vacuum Pump

Before testing, gather the following tools to ensure an effective diagnosis:

- Hand pump: A hand-operated vacuum pump with a gauge, which can be used to create vacuum pressure and measure it.

- Vacuum gauge: Used to measure vacuum levels in the system.

- Wrenches: To disconnect supply lines or other components if needed.

- Safety gloves and goggles: Protect yourself during testing.

- Vacuum supply line: A clear piece of tubing that allows easy observation of airflow.

Step-by-Step Testing Procedure

Testing the vacuum pump involves several steps to ensure that each aspect of the vacuum system is performing as expected.

1. Safety Preparations

- Park your vehicle on a flat surface, engage the parking brake, and disconnect the battery to prevent accidents.

- Make sure the engine is cool, as the vacuum pump and surrounding components may get hot during operation.

2. Locate the Vacuum Pump

The vacuum pump in a Mercedes diesel engine is usually mounted on the engine, driven either by a gear or directly by the camshaft. For Mercedes gas engines, it might be belt-driven or integrated into other components.

Once located, visually inspect the pump and surrounding components for any obvious signs of wear, damage, or leakage, such as cracked supply lines or loose connections.

3. Perform Vacuum Tests

- Check Vacuum Pressure:

- Connect your hand pump or vacuum gauge to the vacuum supply line of the pump.

- Start the engine and observe the reading on the vacuum gauge. A properly functioning pump should create a vacuum of around 20-22 inHg (inches of mercury). For a diesel engine, anything below 15 inHg usually suggests the pump isn’t performing well.

- Check for Vacuum Leaks:

- Use the hand pump to draw a vacuum on the system with the engine off. Once you’ve pumped to a certain level (e.g., 15 inHg), the gauge should hold steady if there are no leaks.

- If the pressure drops, inspect the supply lines, check valves, and connections for leaks.

- Inspect the Check Valves:

- Check valves are designed to prevent backflow. Remove the valve, attach your hand pump, and see if air can flow through in only one direction. If air flows both ways, the check valve is faulty.

4. Check the Braking System

Since the vacuum pump plays a role in power brake assistance, checking the brake booster is also necessary.

- With the engine running, press the brake pedal. If the pedal feels stiff or requires excessive force, it may indicate a problem with either the pump or the brake booster.

Testing Table

| Component Tested | Normal Reading/Outcome | Issue Detected |

|---|---|---|

| Vacuum Pump Pressure | 20-22 inHg | Below 15 inHg |

| Check Valve Function | One-way flow | Flow in both directions |

| Brake Pedal Feel | Responsive, soft braking | Stiff or unresponsive |

Troubleshooting Common Issues

If the vacuum pump does not reach the expected pressure or the vacuum drops, it’s crucial to follow a structured troubleshooting process:

- Inspect for Vacuum Leaks: Often, issues arise from leaks in the supply line or connectors. Spray soapy water on the lines while the engine is running, and look for bubbles indicating air escaping.

- Test the Pump Manually: Using a hand pump to simulate the system is useful for pinpointing exactly where vacuum loss occurs.

- Check the Vacuum Reservoir: If your Mercedes has a vacuum reservoir, ensure it holds vacuum properly and that there are no cracks or damage.

Maintaining the Mercedes Vacuum System

Regular maintenance is key to ensuring your vacuum system works efficiently. Here are some key steps:

- Check Connections Regularly: Make sure all supply lines are securely connected and in good condition. Replace any that appear cracked or brittle.

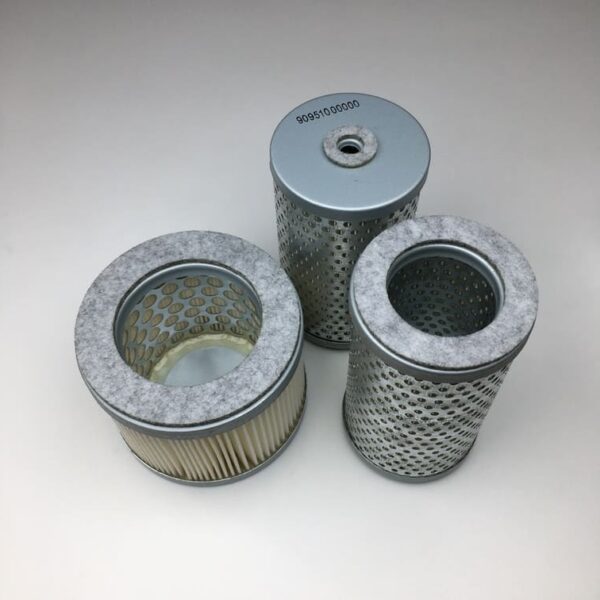

- Inspect Check Valves and Filters: These prevent contamination from entering the vacuum system. Dirty or clogged filters can impact performance, so replace them as needed.

- Routine Diesel Maintenance: In Mercedes diesel models, keep up with regular diesel maintenance schedules, as poorly maintained diesel engines can affect vacuum production.

FAQs

1. How do I know if my vacuum pump is failing?

Typical symptoms include a hard brake pedal, reduced HVAC performance, and door lock malfunctions. Testing with a vacuum gauge is the best way to verify pump health.

2. What should the vacuum pressure be for my Mercedes?

The ideal vacuum pressure is between 20-22 inHg. Anything significantly lower may indicate a failing pump.

3. Can a faulty vacuum pump affect engine performance?

Yes, a failing vacuum pump can cause erratic idling, engine hesitation, and even decreased fuel efficiency.

4. How often should I test my vacuum pump?

Testing should be done annually as part of routine maintenance or whenever you experience any related symptoms like hard brakes or HVAC issues.

5. Where can I find replacement parts for my Mercedes vacuum system?

You can purchase high-quality replacement parts, such as filters and vanes, at vacuumpumppart.com.

6. How do I maintain the vacuum reservoir?

Check the reservoir for leaks and make sure all connections are tight. Replace it if it cannot hold vacuum effectively.

Conclusion

Testing your Mercedes vacuum pump is a straightforward process that can prevent major vehicle issues if done properly. A hand pump, some patience, and attention to detail are all you need to maintain this critical component of your vehicle. Regular testing, troubleshooting, and maintenance of the vacuum pump, check valves, and supply lines will ensure smooth operation of the brake booster, HVAC, and other vital systems.

For quality replacement parts and components, explore our comprehensive collection of Becker vacuum pumps and accessories. Proper maintenance can keep your Mercedes running smoothly, ensuring both safety and comfort on every drive.