How to Test a Purge Valve Without a Vacuum Pump

The purge valve is a crucial component of the evaporative emissions control (EVAP) system, which prevents fuel vapors from escaping into the atmosphere. It works by managing the flow of these vapors from the charcoal canister to the engine’s intake manifold, where they can be burned during combustion. Ensuring that the purge valve functions correctly is vital to maintain the performance and efficiency of your vehicle. But what if you don’t have a vacuum pump for testing? Don’t worry. This article will guide you through the testing of a purge valve without a vacuum pump, using some simple yet effective techniques.

What is a Purge Valve?

The Role of the Purge Valve in the EVAP System

The purge valve is an electrically-operated solenoid that opens and closes to control the movement of fuel vapors. These vapors are stored in the charcoal canister and released back into the engine to be combusted, which prevents them from escaping into the air and contributing to pollution.

- Emission Control: The primary function of the purge valve is to control emissions. When the engine runs, the purge valve opens to allow the stored vapors in the canister to mix with air and fuel in the engine’s intake manifold.

- Performance Maintenance: A malfunctioning purge valve can cause several issues, including rough idling, reduced fuel efficiency, and the dreaded check engine light.

Common Symptoms of a Faulty Purge Valve

A faulty purge valve can manifest in several ways:

- Check Engine Light: The onboard diagnostic system may detect an EVAP issue and trigger the check engine light.

- Rough Idle: If the purge valve is stuck open, it can create a vacuum leak, resulting in a rough idle or difficulty starting the engine.

- Increased Emissions: If the valve doesn’t open or close correctly, the emissions system may fail to operate efficiently, leading to higher than normal emissions.

Tools Needed to Test the Purge Valve Without a Vacuum Pump

While a vacuum pump is the conventional tool for testing a purge valve, there are other ways to test its functionality using simple tools:

- Multimeter: Used to measure electrical resistance.

- Battery or Power Supply: You will need a 12V power source to energize the valve.

- Hoses and Tubing: To feel airflow through the valve.

These are simple and inexpensive tools that can help you verify the operation of your purge valve without needing a vacuum pump.

Testing the Purge Valve Using a Multimeter

Step 1: Locate the Purge Valve

The purge valve is usually found close to the intake manifold or connected to the charcoal canister. Refer to your vehicle’s manual for its exact location.

- Disconnect the Electrical Connector: Ensure the engine is off and remove the electrical connector attached to the purge valve.

- Access the Valve: Make sure you have easy access to the valve’s terminals for accurate testing.

Step 2: Set Up the Multimeter

- Set the Multimeter to Ohms: You want to measure the resistance of the purge valve’s coil. Set the multimeter to the ohms (Ω) setting.

- Connect the Multimeter Leads: Attach the leads to the terminals of the purge valve. You should see a resistance reading.

Resistance Range: The resistance value for a functioning purge valve is usually between 20-50 ohms. A reading significantly outside this range indicates an issue.

| Condition | Reading | Interpretation |

|---|---|---|

| Normal | 20-50 Ω | The coil is in good condition. |

| Open Circuit (No Reading) | ∞ | The coil is broken. |

| Short Circuit (Low Reading) | < 10 Ω | The coil may be shorted. |

Step 3: Interpret the Results

- Normal Range: If the resistance falls within the acceptable range, the electrical coil inside the purge valve is functional.

- Out of Range: If the reading is 0 ohms or very high (∞), the purge valve is faulty and needs replacement.

Testing with a multimeter is an effective way to determine the electrical condition of your purge valve without needing a vacuum pump.

Testing the Purge Valve Mechanically

Another way to test a purge valve without a vacuum pump is to determine whether it opens and closes properly by using airflow checks.

Step 1: Apply Voltage to the Purge Valve

The purge valve is activated by applying a 12V current, similar to what it receives when connected to the car’s electrical system.

- Use a 12V Battery: Connect the positive and negative leads from a 12V battery to the corresponding terminals on the purge valve.

- Listen for a Click: The purge valve is a solenoid, so you should hear a distinct click when voltage is applied, indicating that the valve is actuating.

Step 2: Check for Airflow

To verify if the valve is operating correctly:

- Disconnect the Hoses: Remove the hoses connected to the purge valve.

- Blow Air Through the Valve: With no power applied, the valve should be closed, and air should not pass through.

- Apply 12V Power: When you connect the 12V power source, the valve should open, allowing air to pass through.

This simple test can help you determine whether the valve opens and closes as expected, ensuring that it is capable of managing the flow of vapors effectively.

Common Issues When Testing a Purge Valve

1. Stuck Open or Stuck Closed

A stuck open valve allows unregulated air into the intake manifold, causing poor fuel efficiency and potentially leading to engine misfires. A stuck closed valve prevents the EVAP system from functioning, leading to increased emissions.

Symptoms:

- Stuck Open: High idle, rough running, increased fuel consumption.

- Stuck Closed: Check engine light, trouble codes related to the EVAP system.

2. Electrical Failures

If the solenoid coil inside the valve is faulty, the valve will not operate even if power is applied. In this case, testing with a multimeter is vital.

Prevention Tip: Ensure that all electrical connections are clean and tight to avoid malfunctioning due to connectivity issues.

Preventive Maintenance for Purge Valves

To avoid running into purge valve issues, routine maintenance can go a long way:

- Inspect Hoses Regularly: Check the hoses for cracks, blockages, or wear that could impede the flow of vapors.

- Clean the Valve: In some cases, cleaning the valve can restore functionality if it’s sticking due to buildup.

- Check Electrical Connections: Ensure all connectors and wires are securely attached and free of corrosion.

Regular checks will help you spot potential problems early, saving you from expensive repairs or replacements later.

Tips for Replacing a Faulty Purge Valve

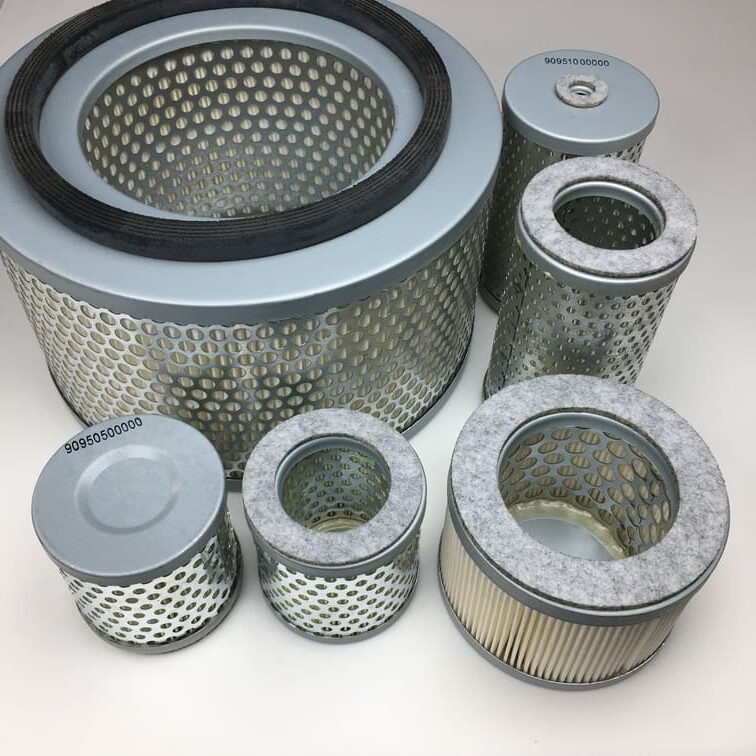

1. Choose High-Quality Parts

When replacing a faulty purge valve, use OEM parts or high-quality aftermarket components to maintain the functionality and efficiency of your EVAP system.

For compatible vacuum parts, explore the Vacuum Pump Spare Parts for dependable replacements.

2. Follow Manufacturer Guidelines

Always follow the manufacturer’s guidelines and specifications when installing a new purge valve. Incorrect installation could lead to further EVAP issues.

3. Avoid Damage to Hoses and Fittings

When removing and reinstalling hoses, avoid twisting or forcing them, as this could cause them to crack or develop leaks over time.

FAQs

1. How do I know if my purge valve is bad?

A bad purge valve often triggers the check engine light and can cause a rough idle, increased emissions, or poor fuel efficiency. Testing with a multimeter or applying 12V to check actuation can confirm the diagnosis.

2. Can I test a purge valve without a vacuum pump?

Yes, you can test a purge valve without a vacuum pump by using a multimeter to check the coil resistance or by applying a 12V power supply to ensure the valve opens and closes correctly.

3. What happens if a purge valve is stuck closed?

If a purge valve is stuck closed, the EVAP system will fail to purge fuel vapors into the engine for combustion, leading to increased emissions and potentially triggering the check engine light.

4. Why does my car idle roughly when my purge valve fails?

A failing purge valve can cause an improper air-fuel mixture, especially if the valve is stuck open, creating a vacuum leak. This can lead to a rough idle and erratic engine performance.

5. How much resistance should a good purge valve have?

A typical purge valve should have a resistance between 20-50 ohms. Values outside this range indicate that the valve’s coil is malfunctioning and needs to be replaced.

Conclusion

Testing a purge valve without a vacuum pump is entirely possible and can be done effectively with the right tools and techniques. Utilizing methods like checking electrical resistance with a multimeter or applying voltage to verify actuation allows for thorough testing, ensuring that your vehicle’s emissions system remains in good working condition. By following the steps outlined, you can confidently diagnose and address any issues without the need for specialized vacuum equipment.