How to Empty a Vacuum Desoldering Pump: A Step-by-Step Guide

If you’re into electronics work, you’ll know that desoldering is an essential process for repairing, modifying, or salvaging electronic components. One of the most useful tools for this is a vacuum desoldering pump. But to maintain its efficiency, it’s important to know how to empty a vacuum desoldering pump properly. In this comprehensive guide, we’ll cover everything you need to know about emptying your vacuum desoldering pump safely and effectively to prolong its lifespan and keep it working at its best.

What is a Vacuum Desoldering Pump?

A vacuum desoldering pump is a tool used to remove molten solder from circuit boards. It is commonly used by hobbyists, technicians, and professionals who work on electronics repairs. The device works by creating a vacuum to quickly suck molten solder away from components, making it easier to replace or repair specific parts.

Key Features of a Vacuum Desoldering Pump

- Effective Solder Removal: Quickly removes molten solder for clean desoldering.

- Temperature Control: Many pumps come with adjustable temperature to match the melting point of different solders.

- Reusable Filter: Some models feature reusable filters that catch solder particles.

| Feature | Description |

|---|---|

| Effective Solder Removal | Ensures precise and fast solder removal |

| Temperature Control | Matches various solder melting points |

| Reusable Filter | Captures debris and helps maintain tool |

“Maintaining a vacuum desoldering pump is crucial to ensure smooth and efficient electronics work. Proper emptying and cleaning can significantly prolong the tool’s lifespan.”

Why You Need to Empty Your Vacuum Desoldering Pump

When you use a vacuum desoldering pump, molten solder is sucked into a chamber or container inside the tool. Over time, this container fills up, which can cause several problems:

- Reduced Efficiency: A full collection chamber will hinder the pump’s suction power.

- Potential Blockage: Solder residue can clog the pump, affecting its performance.

- Overheating: Accumulated solder can make it difficult for the pump to dissipate heat, leading to overheating issues.

Benefits of Regularly Emptying Your Vacuum Desoldering Pump

- Optimal Performance: Ensures strong suction for better solder removal.

- Prevent Blockages: Reduces the risk of clogs that can damage internal components.

- Prolong Tool Lifespan: Proper maintenance extends the life of the pump, saving money in the long run.

| Benefit | Description |

|---|---|

| Optimal Performance | Keeps suction power at its peak |

| Prevent Blockages | Avoids costly repairs or replacements |

| Prolong Tool Lifespan | Saves money by extending the pump’s longevity |

Tip: Make a habit of checking the collection chamber after every major desoldering session to prevent buildup.

Step-by-Step Guide to Emptying a Vacuum Desoldering Pump

Emptying your vacuum desoldering pump is straightforward if you follow these steps carefully. Always ensure that you follow safety procedures during the process.

Step 1: Power Off and Cool Down

First, make sure that the vacuum desoldering pump is powered off and has had enough time to cool down. This is crucial because the pump and the solder inside can be very hot immediately after use.

- Unplug the Pump: Disconnect from any power source.

- Allow Cooling Time: Let the pump cool for about 10-15 minutes to avoid burns.

Step 2: Access the Collection Chamber

Locate the collection chamber or solder reservoir. Depending on your model, this chamber might be accessible by twisting off a cap or removing a latch.

- Twist or Unlock: Open the chamber using the appropriate method as instructed in the manual.

- Remove the Filter: Some models include a filter; be sure to remove this and inspect it for clogs or damage.

Step 3: Dispose of the Solder Waste

Carefully dispose of the collected solder waste. This waste is typically lead-based, so make sure to handle it responsibly.

- Use a Container: Dispose of the solder into a metal container that can withstand heat.

- Avoid Inhaling Fumes: Lead solder is hazardous; work in a well-ventilated area and consider wearing a mask.

Step 4: Clean the Chamber and Filter

Once the solder waste is disposed of, take the time to clean the chamber and filter.

- Brush Residue: Use a small brush to clear away any residue left in the chamber.

- Clean the Filter: If your pump uses a reusable filter, clean it thoroughly by tapping out debris and, if necessary, rinsing it (follow the manufacturer’s guidelines).

| Step | Action |

|---|---|

| Power Off and Cool Down | Ensure the pump is unplugged and cool |

| Access Chamber | Open the collection chamber |

| Dispose Waste | Discard solder safely into a metal container |

| Clean Components | Brush out chamber and clean the filter |

Step 5: Reassemble the Pump

After everything has been cleaned, reassemble the vacuum desoldering pump. Make sure all parts are dry before reassembly to avoid short circuits.

- Replace the Filter: Insert the filter back into its position.

- Close the Chamber: Ensure the chamber is properly sealed to maintain vacuum efficiency.

- Test the Pump: Power on the pump briefly to check if suction is restored.

Troubleshooting Common Issues

1. Weak Suction

If you notice weak suction, it could be due to a partially blocked filter or improperly sealed collection chamber.

- Check the Filter: Make sure the filter is clean and correctly positioned.

- Seal Properly: Verify that the chamber is tightly sealed; any air leaks will compromise suction power.

2. Overheating

Overheating can happen if the pump has not been emptied regularly.

- Regular Maintenance: Ensure the chamber is cleared after each use to allow for proper heat dissipation.

- Cooling Time: Always allow enough cooling time before operating again.

3. No Vacuum Created

If no vacuum is created, there could be a blockage somewhere in the system.

- Inspect the Chamber: Look for solder buildup that may be clogging the airways.

- Clean the Nozzle: Ensure the nozzle is free from any leftover solder or debris.

Pro Tip: For stubborn clogs, consider using a thin wire to clear the nozzle, but be careful not to damage internal components.

Real Internal Links for More Information

If you’re interested in reliable vacuum pumps or need replacement parts for your desoldering work, check out some of these options from our trusted suppliers:

- Carbon Vanes

- 90137301010 | WN 124-205 Original Becker Set of 10 Vanes

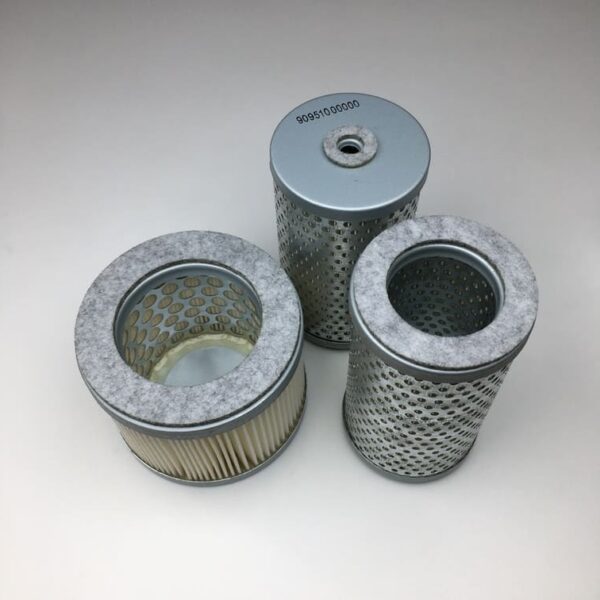

- Becker Air Filter replaces Becker 909540

These links provide access to high-quality spare parts that are ideal for maintaining or upgrading your desoldering tools.

Frequently Asked Questions

1. How often should I empty my vacuum desoldering pump?

You should empty your vacuum desoldering pump after every major desoldering session or whenever the chamber appears full. Regular maintenance helps keep the tool functioning properly.

2. Can I reuse the solder collected in the pump?

No, the collected solder is often contaminated and should not be reused. Always dispose of it in a safe, designated container.

3. What safety precautions should I take while emptying the pump?

Always power off and cool down the pump before emptying. Use gloves and work in a well-ventilated area to avoid exposure to harmful fumes.

4. Why is my vacuum pump losing suction power?

This could be due to a clogged filter or improperly sealed collection chamber. Ensure both are clean and tightly secured.

5. Can I clean the filter with water?

If the manufacturer’s guidelines permit it, you can rinse the filter with water. Make sure it is completely dry before reinserting it into the pump.

Conclusion

Maintaining your vacuum desoldering pump through regular emptying and cleaning is essential for optimal performance and extended tool lifespan. By following the steps outlined in this guide, you can ensure that your pump remains efficient and reliable for all your electronics repair needs. Regular maintenance not only saves you time but also helps avoid costly repairs or replacements down the line. Take good care of your tools, and they’ll take good care of your projects!

For more information on spare parts or additional support, feel free to reach out through our recommended links. We’re here to assist you in keeping your electronic repair tools in perfect working condition.