How Quickly Does a Vacuum Pump Work?

Vacuum pumps are indispensable tools in a variety of industries, from HVAC systems to food processing and medical applications. A common question that arises when discussing vacuum pumps is, “How quickly does a vacuum pump work?” The speed of a vacuum pump can greatly impact the efficiency of your operations, whether you are working on refrigeration, drying processes, or degassing applications. In this article, we will explore how the speed of a vacuum pump is determined, the factors that influence its performance, and how to select the right pump for your specific needs.

Understanding Vacuum Pump Speed

The speed at which a vacuum pump works is typically measured by its pumping speed, also known as the pumping capacity. Pumping speed is expressed in units such as cubic feet per minute (CFM) or liters per second (L/s), indicating the volume of gas a pump can remove from a system per unit of time.

What is Pumping Speed?

Pumping speed refers to how quickly a vacuum pump can reduce the pressure in a closed system by removing gases. For instance:

- Higher CFM/L/s: Indicates a pump that can evacuate gas at a faster rate, effectively reaching a vacuum in a shorter amount of time.

- Lower CFM/L/s: Indicates a slower process, which may be suitable for applications that do not require rapid vacuum achievement.

Types of Vacuum Pumps and Their Typical Speeds

Different types of vacuum pumps offer varying speeds depending on their design and intended application:

- Rotary Vane Pumps: Typically have a pumping speed ranging from 3-12 CFM. They are commonly used in refrigeration and HVAC applications due to their consistent performance.

- Diaphragm Pumps: These pumps offer lower pumping speeds and are often used for applications that require a clean and oil-free vacuum, such as laboratory settings.

- Turbomolecular Pumps: Used for achieving ultra-high vacuums, these pumps can have very high pumping speeds, suitable for high-precision applications like semiconductor manufacturing.

Choosing the right vacuum pump with the appropriate speed is crucial for ensuring the efficiency and reliability of your processes.

Factors Affecting the Speed of a Vacuum Pump

Several factors can impact how quickly a vacuum pump works, including the type of pump, system volume, ultimate vacuum, and operating conditions.

1. Type of Vacuum Pump

The type of pump you select will directly influence its speed. For example:

- Rotary vane pumps are faster in achieving a medium vacuum, while diaphragm pumps might be slower but provide a clean, oil-free vacuum.

- Roots blowers, often used as booster pumps, can greatly enhance the speed when used in conjunction with another primary vacuum pump.

2. System Volume

The volume of the system that needs to be evacuated plays a critical role in determining how quickly a vacuum pump will work.

- Small Volumes: Reaching the desired vacuum level is quicker in systems with small volumes.

- Large Volumes: Larger volumes require more time to evacuate, especially if the pump has a lower CFM rating.

Consider a vacuum degassing chamber. A small chamber with a rotary vane pump operating at 5 CFM will reach a vacuum state faster compared to a large chamber using the same pump.

3. Ultimate Vacuum Level Required

Different applications require different ultimate vacuum levels. A pump working to achieve a high vacuum will generally take longer than one aiming for a rough or medium vacuum.

- Rough Vacuum: Achievable in a shorter amount of time.

- High Vacuum: Requires more effort and time, often involving multiple stages of pumping.

4. Leaks and Restrictions

System leaks and restrictions can drastically affect how quickly a vacuum pump works. Even a small leak can significantly slow down the vacuum process as the pump has to work continuously to remove the incoming air.

- Seal Quality: Make sure that all gaskets, seals, and connections are tight to prevent leaks.

- Hose Restrictions: Narrow or long hoses can restrict flow, thereby increasing the time needed to reach a desired vacuum.

Tips to Improve Pumping Speed

- Use Shorter Hoses: Minimize the hose length and diameter to reduce resistance and improve speed.

- Ensure Proper Maintenance: Regularly replace worn-out seals and check for leaks to maintain efficiency.

Common Applications and Speed Requirements of Vacuum Pumps

1. Refrigeration and HVAC Systems

For refrigeration and HVAC systems, achieving a proper vacuum is critical to remove moisture and air before charging the system with refrigerant. In these applications, a typical rotary vane pump with a speed of 5-8 CFM is sufficient for most residential and commercial systems.

- Time Required: On average, a properly sized vacuum pump can achieve the necessary vacuum for an HVAC system within 15-30 minutes, depending on the system volume and conditions.

2. Resin Degassing and Mold Making

When working with resin or silicone molds, achieving a vacuum quickly helps to remove bubbles before the material sets.

- Speed and Efficiency: A 3-5 CFM rotary vane pump can usually degas resin within 5-10 minutes, depending on the viscosity of the resin and the volume of the container.

3. Medical and Laboratory Use

In medical and laboratory settings, vacuum pumps are often used for filtration, aspiration, and drying processes.

- Speed Considerations: Diaphragm pumps used in these environments may operate at a slower speed, but the focus is more on achieving a clean vacuum rather than how quickly it happens.

Choosing the Right Vacuum Pump for Your Needs

1. Evaluate Your Application Requirements

Before selecting a vacuum pump, determine the specific requirements of your application:

- Volume to be Evacuated: Larger volumes will need a pump with higher CFM to ensure quick evacuation.

- Required Vacuum Level: Different processes require different vacuum levels, from rough vacuum (low level) to high vacuum.

- Nature of Materials: In processes like degassing or drying, you need to consider whether you need an oil-free pump or if the system can handle oil contamination.

2. Balance Speed with Efficiency

Sometimes, the fastest pump isn’t necessarily the best option. Balancing pumping speed with the cost, maintenance needs, and suitability for the process is crucial for making a cost-effective decision.

- Rotary Vane vs. Diaphragm: A rotary vane pump may be fast, but a diaphragm pump might be more suitable for certain clean environments where speed is less critical.

For additional information on selecting the right vacuum pump, check out the Vacuum Pump Spare Parts Guide. This guide will help you navigate through options to find the best fit for your needs.

Maintenance Practices for Optimal Pumping Speed

Maintaining your vacuum pump properly ensures it continues to operate at peak efficiency, effectively shortening the time required to achieve a vacuum.

1. Regular Oil Changes

If you’re using an oil-sealed rotary vane pump, regular oil changes are critical to ensure that the pump runs efficiently. The oil helps to lubricate and seal the internal components, which in turn affects the speed of achieving a vacuum.

- Recommended Frequency: Change the oil every 500 hours of operation or when it starts to darken. Darkened oil may indicate contamination and can reduce the pump’s effectiveness.

2. Clean and Inspect Seals and Filters

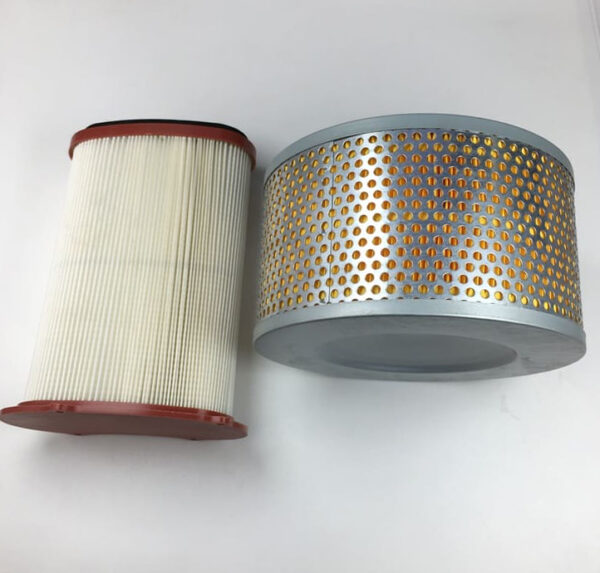

- Inspect Seals: Look for cracks or wear, as damaged seals can lead to vacuum leaks that slow down pumping.

- Change Filters: Keep the air filters clean to avoid obstructions that might limit the pump’s efficiency.

For further maintenance parts, you can view Becker Air Filter Replacements to ensure your vacuum pump remains in optimal condition.

3. Proper Storage and Handling

When the vacuum pump is not in use, ensure it is stored properly to avoid contamination or damage. Keeping the pump clean and free of debris will help in reducing maintenance needs and improving operational speed over time.

FAQs

1. How long does it take for a vacuum pump to create a full vacuum?

The time required depends on the pump’s capacity (CFM), the system volume, and the ultimate vacuum needed. For most small applications, a rotary vane pump can create a vacuum in 5-15 minutes.

2. Does the size of the vacuum pump affect how quickly it works?

Yes, the CFM rating of the pump directly impacts the speed. A larger pump (higher CFM) can evacuate a system more quickly compared to a smaller one.

3. Can leaks in the system affect the pumping speed?

Absolutely. Even small leaks can significantly slow down how quickly a vacuum is achieved, as the pump will have to continually remove incoming air.

4. What type of pump is best for fast evacuation?

For rapid evacuation, a rotary vane pump with a high CFM rating is ideal. These pumps are commonly used for applications requiring quick vacuum creation.

5. How can I improve the speed of my vacuum pump?

To improve speed, ensure all connections are tight, use shorter hoses to reduce flow resistance, and maintain the pump by regularly changing oil and inspecting seals.

Conclusion

The speed of a vacuum pump is influenced by several factors, including the type of pump, system volume, and ultimate vacuum level required. Different applications may require different types of pumps—rotary vane pumps for quick evacuation or diaphragm pumps for cleaner operations. Choosing the right pump for your needs, maintaining it well, and optimizing your system setup can all play key roles in achieving the desired vacuum quickly and efficiently.

Whether you need a vacuum pump for HVAC, resin degassing, or medical applications, understanding its speed and how to optimize it will save you time and improve your operational effectiveness. For more resources and tools related to vacuum pumps, including replacement parts and maintenance tips, visit Vacuum Pump Spare Parts. Proper knowledge and maintenance can significantly enhance the efficiency and speed of your vacuum pump, ensuring that it serves your needs effectively for years to come.