How Often Should You Replace Your Vacuum Pump Filter?

Vacuum pumps are essential components in a wide variety of industrial and laboratory settings. A crucial part of keeping these systems working efficiently is the vacuum pump filter. But how often should you replace a vacuum pump filter to ensure optimal performance and prolong the life of your equipment? In this article, we’ll explore this question in-depth, providing insights and best practices for replacing your vacuum pump filter.

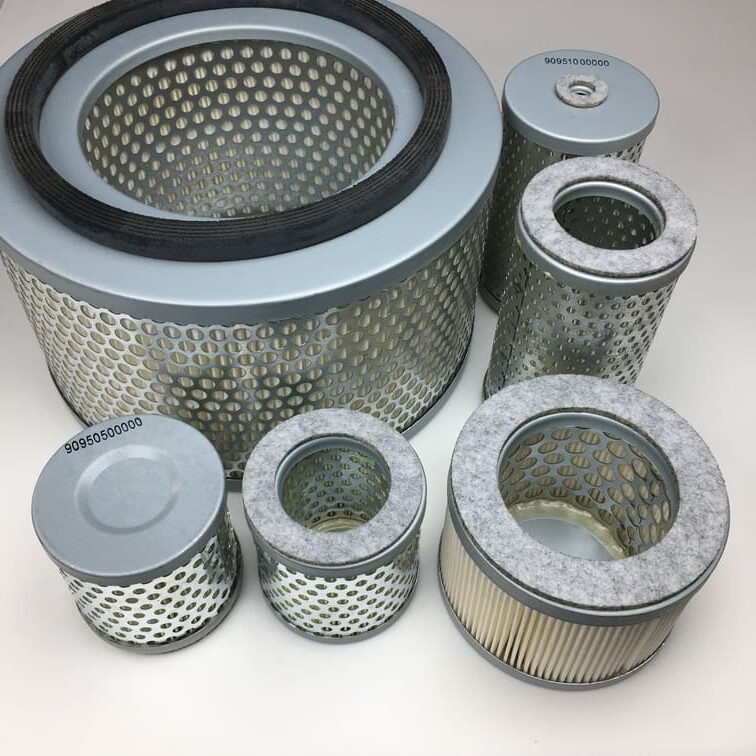

1. Introduction to Vacuum Pump Filters

A vacuum pump filter is a key component that helps to protect the pump and maintain its efficiency by removing contaminants such as dust, particles, and moisture from the air or gas before it reaches the pump. This simple yet effective mechanism ensures that the pump continues to operate smoothly and without interference.

The frequency of replacing your vacuum pump filter largely depends on several factors such as usage, environment, and the type of pump you have. Not replacing the filter on time can lead to a decrease in efficiency, increased maintenance costs, and even potential damage to the pump itself.

“Regular filter maintenance is crucial for the longevity of your vacuum pump.”

Keeping these considerations in mind can help you determine the best schedule for replacing your vacuum pump filter. In the following sections, we will take a detailed look at each factor that affects filter replacement frequency.

2. Why is the Filter Important for a Vacuum Pump?

The primary role of a vacuum pump filter is to prevent contaminants from entering the pump mechanism. Contaminants can include dust particles, aerosols, and even oil mists that can originate from the vacuum environment or from the pump itself. Over time, these contaminants can accumulate and potentially cause blockages or damage critical pump components.

- Protection from Damage: Filters help prevent debris from damaging the pump’s moving parts, which is critical in prolonging the pump’s lifespan.

- Efficiency Improvement: When contaminants are filtered out, the vacuum pump operates more efficiently, reducing energy consumption and maintaining optimal vacuum levels.

- Cost-Effective Maintenance: By replacing filters regularly, you can prevent costly repairs and avoid downtime that can occur due to damaged pump components.

A good analogy is considering the vacuum pump filter as similar to the air filter in your car. Just as your engine requires clean air to function properly, your vacuum pump needs clean airflow to operate efficiently.

| Benefit | Impact on Vacuum Pump |

|---|---|

| Reduced Wear and Tear | Longer lifespan and reduced repairs |

| Improved Operational Efficiency | Better performance and energy savings |

| Consistent Vacuum Quality | Reliable process outcomes |

3. Factors Determining the Frequency of Filter Replacement

There isn’t a one-size-fits-all answer to how often you should replace your vacuum pump filter. The replacement frequency will vary depending on several factors, including:

a. Type of Vacuum Pump

Different types of vacuum pumps—such as rotary vane, screw, or liquid ring—may have different requirements for filter maintenance. For instance:

- Rotary Vane Pumps: Typically require more frequent filter changes, especially in environments where the air is dusty or contaminated.

- Screw Pumps: These pumps may have less frequent filter replacement intervals since they often deal with cleaner environments.

b. Operating Environment

The environment in which your vacuum pump is used significantly impacts filter replacement frequency.

- Dusty or Polluted Areas: Filters may need to be replaced every few months to prevent contaminants from clogging the pump.

- Clean Laboratory Conditions: In controlled settings like laboratories, the filters may last much longer, sometimes requiring only annual replacements.

c. Usage Hours

The frequency of vacuum pump use is a key factor. Pumps that operate continuously will accumulate contaminants faster than those used occasionally.

- Continuous Operation: Filters might need replacing as frequently as every 3 to 6 months.

- Intermittent Use: For pumps used sporadically, an annual checkup and potential replacement may suffice.

| Usage Condition | Recommended Replacement Frequency |

|---|---|

| Continuous Use | Every 3-6 months |

| Intermittent Use | Every 6-12 months |

4. Signs That Your Vacuum Pump Filter Needs Replacement

It’s important to keep an eye out for signs that indicate your vacuum pump filter may need replacing. Ignoring these signs can lead to bigger problems down the line, including pump failure. Here are some common indicators:

- Decreased Pump Efficiency: If you notice that the pump isn’t reaching the expected vacuum levels or is taking longer to do so, it could be a sign of a clogged filter.

- Increased Noise Levels: An unusual increase in noise could indicate that the pump is working harder than necessary, potentially due to a blocked filter.

- Oil or Fluid Contamination: For oil-sealed pumps, if you observe contamination in the pump oil, it could mean that the filter is no longer effective at keeping contaminants out.

Pro Tip: Regularly schedule maintenance checks to avoid unexpected downtime. Identifying these signs early can help you replace filters before they affect the entire system.

5. How to Replace Your Vacuum Pump Filter

Replacing the filter in your vacuum pump is typically a straightforward process, but it is important to follow the manufacturer’s guidelines for your specific model. Here’s a general guide:

Step-by-Step Replacement Guide

- Turn Off and Isolate the Pump: Always ensure the pump is turned off and disconnected from any power source to prevent accidents.

- Access the Filter Housing: Most vacuum pumps have an easily accessible filter compartment.

- Remove the Old Filter: Carefully take out the old filter, checking for any visible signs of damage or contamination.

- Install the New Filter: Place the new filter in the compartment, ensuring it fits securely.

- Secure the Filter Housing: Once the new filter is in place, close the housing tightly to prevent leaks.

- Run a Test: After replacing the filter, turn on the pump and ensure it is operating smoothly and reaching the desired vacuum level.

Note: Always use filters that are compatible with your specific vacuum pump model to avoid performance issues.

6. Benefits of Timely Filter Replacement

Replacing your vacuum pump filter on time has multiple benefits, all of which contribute to better performance, reduced costs, and a longer lifespan for your equipment:

- Improved Efficiency: A clean filter means the pump can work as intended, reducing the load on the motor and maintaining optimal efficiency.

- Reduced Repair Costs: By keeping contaminants away from critical components, you can prevent wear and tear that could lead to costly repairs.

- Longer Lifespan: Just like regular oil changes for your car, timely filter replacements extend the life of the pump, ultimately providing a better return on your investment.

7. Common Mistakes to Avoid

While maintaining your vacuum pump filter, it’s important to avoid some common pitfalls:

- Using the Wrong Filter Type: Not all filters are created equal, and using an incorrect filter could lead to reduced efficiency or damage.

- Ignoring Replacement Schedules: Many operators forget to replace filters on time, leading to reduced performance and potential damage to the pump.

- Not Checking for Leaks: After replacing the filter, always check for any air leaks to ensure that the filter is correctly installed.

8. Conclusion: Prioritizing Vacuum Pump Filter Maintenance

Vacuum pump filters are small but vital components that can make a big difference in the efficiency and longevity of your pump. By understanding when and how to replace these filters, you can ensure that your vacuum pump continues to operate smoothly and effectively for years to come.

Remember, each type of vacuum pump and application environment may have specific needs, so always refer to the manufacturer’s guidelines and seek expert advice if you are unsure.

For more information on vacuum pump maintenance and selecting the right filters, visit Vacuum Pump Parts. We offer a wide range of resources and products to help you keep your vacuum systems running at peak performance.

FAQs

1. How often should you replace a vacuum pump filter?

It depends on the type of pump, the environment, and how often the pump is used. For continuous use in dusty environments, replace the filter every 3-6 months.

2. What happens if I don’t replace my vacuum pump filter?

If not replaced, a dirty filter can lead to decreased efficiency, increased wear and tear on the pump, and potential system failure.

3. Can I clean a vacuum pump filter instead of replacing it?

Some filters can be cleaned, but it depends on the type. In most cases, replacement is recommended for optimal performance.

4. How do I know if my vacuum pump filter needs replacement?

Look for signs such as decreased vacuum levels, increased noise, and visible contamination in pump oil.

5. What type of filter should I use for my vacuum pump?

Always use filters that are compatible with your specific vacuum pump model. Refer to the manufacturer’s guidelines or contact a specialist.

6. How does the environment affect filter replacement frequency?

Dusty or polluted environments will require more frequent filter changes compared to clean, controlled settings like laboratories.

If you need further assistance or would like to speak with our experts about maintaining your vacuum pump, don’t hesitate to contact us. We’re here to help ensure your systems run smoothly and efficiently.