How Much Vacuum Should Be Between a Filter and Pump?

When it comes to vacuum pumps, understanding the pressure dynamics is crucial for proper functioning and maintenance. Whether you’re dealing with a vacuum pump used in automotive systems or an industrial setup, maintaining the right level of vacuum between the filter and pump is essential for efficiency and safety. In this comprehensive guide, we’ll explore how much vacuum should be maintained between a filter and a pump, how to measure it, and how different factors can affect it. This is an important consideration in systems where optimal vacuum levels ensure the efficiency and longevity of both the pump and filtration unit.

Understanding the Role of Vacuum in Pump and Filter Systems

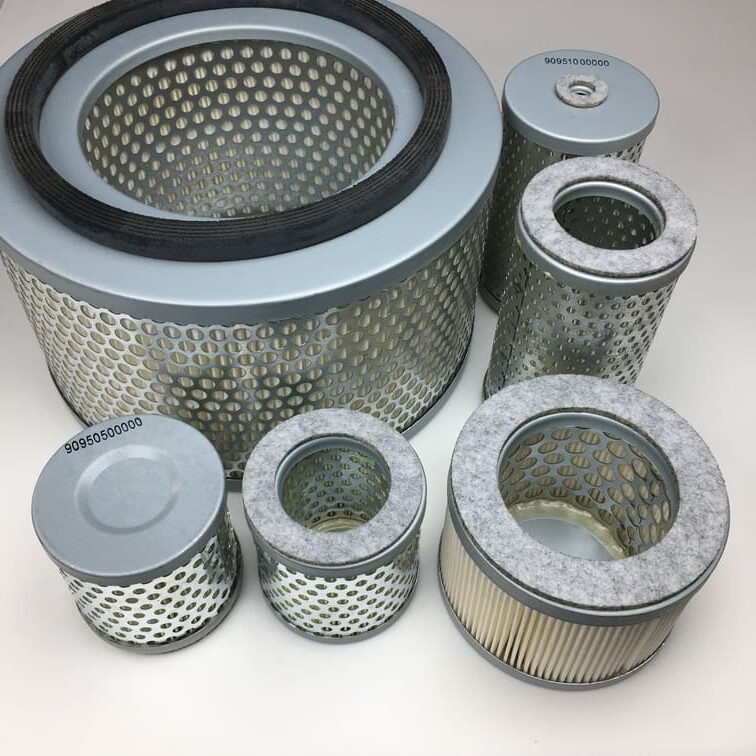

In a vacuum pump setup, the filter plays an important role in ensuring that contaminants do not reach the pump. This is critical because even small particles can cause damage to the pump, reducing its lifespan and efficiency.

- The vacuum level between the filter and pump is an indication of how well the system is working.

- If the vacuum is too high or too low, it can mean that the system is either not drawing air efficiently or there is a blockage in the line.

Maintaining the correct vacuum level ensures that the pump is protected and that the system functions smoothly without unnecessary wear and tear.

Key Terms to Know:

- Vacuum Pump: A device used to create a vacuum by removing gas molecules from a sealed volume.

- Filter: A component used to capture particles or contaminants, preventing them from reaching the pump.

- Vacuum Level: Measured in inches of mercury (Hg) or millibars (mbar), it represents the pressure difference that the vacuum pump creates.

“An optimal vacuum between the filter and pump ensures maximum efficiency, preventing wear and promoting long pump life.” – Super Member Mechanic

Typical Vacuum Levels Between Filter and Pump

The amount of vacuum between a filter and a pump largely depends on the type of system and the application in which the pump is being used. Below are typical vacuum levels for different systems:

Automotive Vacuum Pump Systems

In automotive applications, particularly for vehicles like Rio Grande or other similar models, the vacuum pressure between the filter and pump can range between 15 to 20 inches of mercury (Hg). This level ensures that the pump draws the right amount of air to assist with brake boosting, HVAC, or emissions control.

- Normal Range: 15-20 in Hg.

- Low Vacuum: May indicate leaks or blockages in the filter.

- High Vacuum: Could signal restrictions in the intake, possibly a clogged filter.

Industrial and Laboratory Systems

In industrial vacuum systems, such as those using Becker vacuum pumps, the vacuum pressure between the filter and pump often needs to be controlled more precisely. Typical readings here may be between 50 to 100 millibars depending on the specific use case.

| Application Type | Typical Vacuum Level |

|---|---|

| Automotive Systems | 15-20 in Hg |

| Industrial Vacuum System | 50-100 millibars |

Factors Affecting Vacuum Between a Filter and Pump

There are several factors that can affect the vacuum level between the filter and the pump. Understanding these is critical for troubleshooting and ensuring that the system operates at peak efficiency.

1. Condition of the Filter

The filter’s condition is one of the most important factors. A dirty or clogged filter will result in an increase in the vacuum level, making it difficult for the pump to draw air efficiently.

- Clean Filter: Allows air to pass freely, keeping vacuum levels within the optimal range.

- Clogged Filter: Causes a higher vacuum reading, as air has difficulty moving through the system.

“Regular maintenance of the filter is key to ensuring optimal performance of your vacuum system.” – Platinum Member Mechanic

2. Pump Type and Capacity

The type and capacity of the vacuum pump will also determine the ideal vacuum level between the filter and pump. Different pumps, such as diaphragm pumps, rotary vane pumps, or piston pumps, have varying requirements for optimal vacuum pressure.

- Rotary Vane Pumps (commonly used in applications like the Becker vacuum system) need a consistent vacuum level, which can be easily disrupted by incorrect filter maintenance.

- Diaphragm Pumps: Generally more forgiving but still require a clean filter for optimal operation.

Maintaining the Correct Vacuum Between Filter and Pump

Step 1: Measure the Vacuum Level

To measure the vacuum level between the filter and pump, you’ll need a vacuum gauge. The gauge should be connected to a port between the filter and the pump to provide an accurate reading.

Tools Needed:

- Vacuum Gauge: To measure the pressure difference.

- Fittings and Hoses: Proper connections to ensure there are no leaks in the system.

Pro Tip: Use a vacuum gauge that can measure down to small increments, as this allows for more precise readings in industrial settings.

Step 2: Adjust or Replace Filters

If the vacuum level is not within the recommended range, consider checking the filter.

- Clean or Replace Filters: Cleaning a dirty filter or replacing it altogether can bring the vacuum level back into its optimal range.

- Check Connections: Ensure all hose connections between the filter and pump are secure and free from leaks.

Regular Maintenance:

- Replace filters every 3-6 months depending on the application.

- Inspect hose fittings for wear and tear and replace if necessary.

Common Issues and Troubleshooting

Problem: Low Vacuum Level

If the vacuum level is lower than expected, this often points to a leak somewhere in the system.

Possible Causes:

- Loose Hose Connections: A leak can occur if hoses aren’t securely attached.

- Damaged Seals: O-rings and gaskets can wear over time, leading to leaks.

Solutions:

- Tighten all connections and ensure that all fittings are properly sealed.

- Replace worn seals and gaskets.

Problem: High Vacuum Level

If the vacuum level is too high, it could indicate blockage or restriction in the line, likely due to a dirty filter.

Possible Causes:

- Clogged Filter: A filter that has not been replaced or cleaned in a long time may impede air flow.

- Collapsed Hose: A collapsed hose will restrict airflow, leading to a higher vacuum level.

Solutions:

- Replace the filter if it’s clogged.

- Inspect hoses for signs of collapse or wear, and replace them as needed.

Internal Links for In-Depth Guidance

To further enhance your understanding of vacuum dynamics, you may refer to some of our detailed guides on filters and pumps, which are available at vacuumpumppart.com.

- Carbon Vanes for Rotary Vacuum Pumps – Learn about the role of carbon vanes and their effect on vacuum systems.

- Vacuum Pump Maintenance Guide – Discover detailed steps for maintaining vacuum pumps and ensuring optimal vacuum pressure.

Frequently Asked Questions

1. What is the ideal vacuum level between a filter and a pump?

The ideal vacuum level between a filter and a pump depends on the application. In automotive systems, it typically ranges from 15 to 20 inches of mercury (Hg), while in industrial settings, it may range from 50 to 100 millibars.

2. How do I measure the vacuum between a filter and pump?

To measure the vacuum between a filter and pump, use a vacuum gauge. Connect it to a port between the filter and pump, ensuring all fittings are tight and secure for an accurate reading.

3. What causes a high vacuum reading between the filter and pump?

A high vacuum reading often indicates a clogged filter or another blockage in the system. Cleaning or replacing the filter usually resolves the issue.

4. Why is it important to maintain the right vacuum level between the filter and pump?

Maintaining the right vacuum level is crucial for protecting the pump from damage, ensuring efficiency, and preventing unnecessary wear and tear.

5. How often should I replace the filter in my vacuum system?

Filters should generally be replaced every 3-6 months, depending on the frequency of use and the operating environment.

Conclusion

Maintaining the correct vacuum level between a filter and pump is essential for ensuring the efficiency, safety, and longevity of the entire vacuum system. Whether for an automotive, laboratory, or industrial application, understanding how to achieve and maintain the right vacuum level can help avoid common issues such as pump wear, inefficient operation, or even system failure. Regular maintenance, including replacing filters and checking connections, will go a long way in keeping your system running smoothly.

For more resources, guides, and high-quality spare parts, visit our vacuum pump parts store. Understanding your vacuum pump system fully will empower you to troubleshoot effectively and keep your system working at peak performance.