When considering investing in a 10 CFM vacuum pump, you need to understand its purpose, cost, and different applications. Whether you’re dealing with an automotive shop, HVAC systems, or industrial processes, these pumps are widely used for removing air from enclosed spaces, providing a controlled vacuum. But what exactly do you need to know before making such an investment? In this article, we’ll break down the components of a 10 CFM vacuum pump, their different types, how much they cost, and what factors influence their pricing.

Understanding CFM and Its Importance

What is CFM?

CFM stands for Cubic Feet per Minute, and it represents the volume of air the pump can move in a minute. In vacuum pumps, CFM indicates the pump’s capacity—essentially how quickly it can remove air from a chamber or container. The higher the CFM rating, the larger the volume of air that can be evacuated, which translates to faster and more effective vacuum performance.

A 10 CFM vacuum pump is generally suited for applications like HVAC servicing, automotive AC recharging, and small-scale industrial work. The pump’s rating directly influences the speed and efficiency of the task, making it crucial to select the right CFM based on your requirements.

Table 1: Applications by CFM Level

| CFM Rating | Typical Applications | Suitable Users |

|---|---|---|

| 3-6 CFM | Small HVAC repairs | Home service technicians |

| 10 CFM | Automotive, HVAC servicing, labs | Professionals, workshops |

| 20+ CFM | Large-scale industrial applications | Factories, large companies |

“Choosing the right CFM level is all about understanding your needs. A 10 CFM pump is ideal for those who need versatility without compromising on efficiency.”

Types of 10 CFM Vacuum Pumps

There are several types of 10 CFM vacuum pumps, each suited for different applications and needs. Let’s look into the three main types of pumps:

1. Rotary Vane Pumps

Rotary vane pumps are among the most commonly used vacuum pumps. They employ carbon vanes to create a vacuum by trapping air and compressing it, which makes them ideal for medium-scale operations.

- Pros: Reliable, efficient, affordable replacement parts.

- Cons: Requires regular maintenance and vane replacement.

Need high-quality parts? Check out the Original Becker Set of 5 Vanes.

2. Diaphragm Pumps

These pumps use a diaphragm to create a vacuum and are best suited for laboratory applications or tasks that require a clean vacuum. Because they don’t rely on oil, they are well-suited for sensitive environments.

- Pros: Oil-free operation, minimal maintenance.

- Cons: Limited power compared to rotary vane pumps.

3. Scroll Pumps

Scroll pumps utilize two spiral-shaped scrolls—one fixed and one orbiting—to compress and remove air. They are often used for high-end applications where contamination control is key, such as medical and scientific uses.

- Pros: Quiet, efficient, and provides a clean vacuum.

- Cons: More expensive and complex.

Table 2: Comparison of Vacuum Pump Types

| Type | Maintenance | Noise Level | Cost Range ($) |

|---|---|---|---|

| Rotary Vane | Medium | Moderate | 300 – 500 |

| Diaphragm | Low | Low | 400 – 700 |

| Scroll | High | Very Low | 1000+ |

A good quality 10 CFM rotary vane pump provides an excellent balance of price and performance, which is why they are the most common choice for general industrial uses.

Factors That Influence the Cost of a 10 CFM Vacuum Pump

The price of a 10 CFM vacuum pump can vary significantly, depending on several factors. Here are some of the most important factors to consider:

1. Brand and Manufacturer

The brand of the pump often dictates its cost. Trusted names in vacuum technology tend to be more expensive but offer reliability and long-term support. Investing in a reputable brand can save you money in the long run, particularly in terms of maintenance and durability.

2. Build Quality and Materials

Pumps made from high-quality materials, such as stainless steel, or with enhanced wear resistance, are more expensive than those made from cheaper components. They are, however, more resistant to wear and tear, which increases their lifespan.

- Carbon vanes, for example, are a critical component that needs to be replaced periodically. Ensuring you use quality vanes can enhance the pump’s lifespan.

For top-quality replacements, consider the Original Becker Set of 10 Vanes.

3. Oil vs. Oil-Free Models

Oil-lubricated models tend to be more affordable initially but require regular oil changes and upkeep, which can add to the total cost of ownership. Oil-free pumps, while often pricier up front, require less ongoing maintenance.

- Oil-Lubricated Pumps: Cheaper but more maintenance-intensive.

- Oil-Free Pumps: More costly upfront, but lower maintenance over time.

4. Accessories and Add-Ons

Many vacuum pumps come with optional accessories that can increase their versatility—such as backlit oil reservoirs, specialized adapters, or digital displays. These add-ons can also drive up the overall cost.

Price Range Overview

A typical 10 CFM vacuum pump can cost anywhere between $300 to $1500, depending on the features, brand, and type. Rotary vane pumps are usually in the lower end of the spectrum, while scroll pumps can hit the higher end.

Best Uses for a 10 CFM Vacuum Pump

HVAC and Refrigeration

In the HVAC industry, vacuum pumps are used to remove moisture and non-condensable gases before charging a system with refrigerant. A 10 CFM vacuum pump provides the right balance between power and speed, making it suitable for medium to large HVAC systems.

Automotive Applications

For automotive use, these pumps are great for air conditioning repairs. They effectively remove any moisture from the system, which could otherwise cause blockages or reduce system efficiency.

- Tip: Always ensure the pump is maintained properly by checking the oil condition regularly and replacing it as needed. Clean oil equals a more efficient pump.

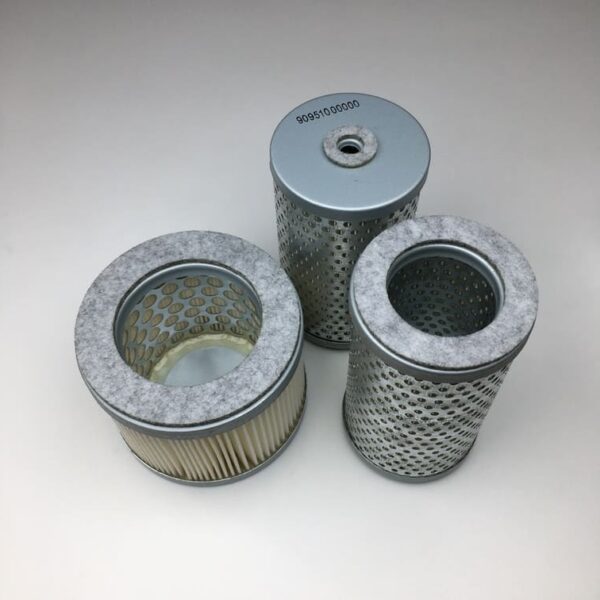

Extend the life of your pump with our Becker Air Filter.

Laboratory and Research Applications

Laboratories often need a clean vacuum for various experiments and sample preparations. Oil-free diaphragm pumps or scroll pumps with 10 CFM ratings provide the ideal solution for labs that need consistent vacuum with no risk of contamination.

Maintenance Tips for 10 CFM Vacuum Pumps

Proper maintenance of your vacuum pump not only ensures optimal performance but also extends its lifespan, giving you better value for your investment. Here are some key maintenance tips:

1. Regularly Check Oil Levels

If your vacuum pump is oil-lubricated, regularly checking and changing the oil is crucial. Dirty oil can lead to reduced pump efficiency and even damage.

- Change the oil whenever it appears dark or cloudy.

2. Replace Filters and Vanes

Replacing worn-out parts like filters and carbon vanes is essential for keeping the vacuum pump operating at peak efficiency. Always use genuine parts to prevent malfunctions or damage to the pump.

- Replace air filters periodically to ensure clean airflow and consistent vacuum levels.

3. Clean the Pump Exterior

Dust and debris can accumulate on the exterior of the pump, which may cause it to run hotter than usual. Wipe the exterior with a clean cloth to prevent overheating and improve longevity.

Regular maintenance is key to extending your pump’s life. For a complete set of vacuum vanes, visit our Vacuum Pump Spare Parts page.