How Many Types of Vacuum Pump Filters Are There?

In the world of industrial applications, vacuum pumps are essential for a wide range of uses, from chemical processing to semiconductor manufacturing. To ensure these pumps operate efficiently and safely, various filters are used to manage contamination, protect the pump, and prolong its life. In this article, we’ll explore the different types of vacuum pump filters, their purposes, and the importance of selecting the right one for your system.

Whether you’re a beginner learning about vacuum systems or a seasoned professional in need of more advanced insights, this guide covers it all. Let’s dive into the many types of vacuum pump filters available, their uses, and how they can enhance your system’s efficiency.

Understanding the Role of Filters in Vacuum Pumps

Vacuum pumps are crucial components in industries that require a controlled atmosphere free from unwanted particles or gases. Over time, these pumps can accumulate contaminants, which, if not properly managed, can significantly impair the pump’s efficiency and cause irreversible damage. This is where vacuum pump filters come into play.

Filters serve as protective barriers, ensuring that particles, dust, oil mist, and other contaminants are captured before they can damage the system. They play an important role in maintaining a vacuum pump’s performance, extending its operational life, and protecting the overall vacuum system.

Key functions of vacuum pump filters include:

- Removal of Particles: Filters prevent solid particles from entering the pump and causing mechanical wear or damage.

- Oil Separation: Some filters ensure the removal of oil mist from the exhaust air.

- Protection Against Backstreaming: Filters prevent oil or other contaminants from flowing back into the vacuum line, protecting sensitive equipment.

Selecting the right filter is crucial to maintaining the efficiency of the vacuum pump, reducing maintenance costs, and ensuring a longer lifespan for the system.

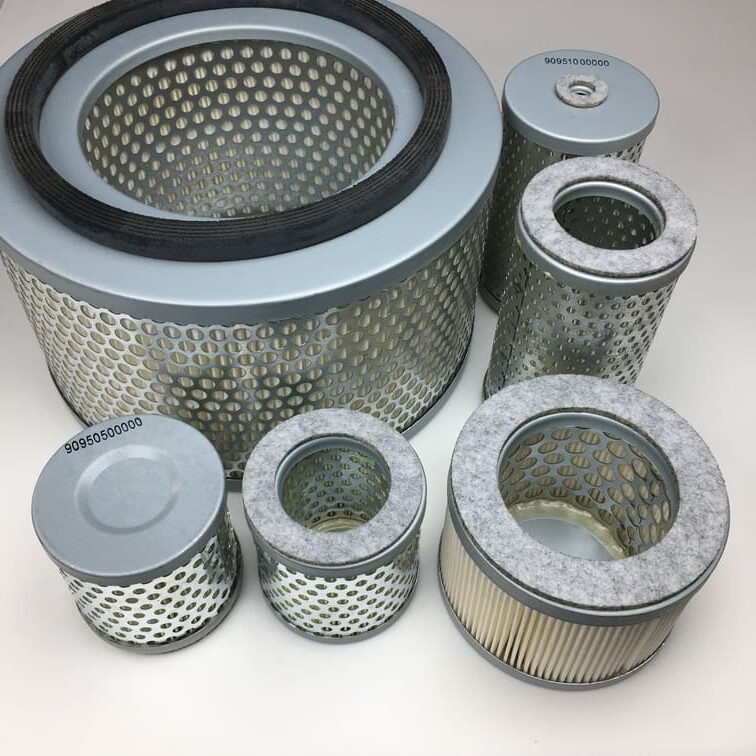

Types of Vacuum Pump Filters

Vacuum pump filters come in various types, each serving specific purposes. Here, we outline the main categories of vacuum pump filters and explain their applications.

1. Inlet Vacuum Pump Filters

Inlet filters are designed to clean the air or gas entering the vacuum pump. These filters are critical because they stop contaminants from entering the pump, thus minimizing mechanical wear and tear.

- Function: Protect the vacuum pump by filtering out dust, particulate matter, and contaminants.

- Applications: Used extensively in dusty environments or where the air quality is poor.

- Filter Media: Typically uses pleated paper, polyester, or sintered metal elements.

The use of inlet vacuum pump filters is common in industries like food processing, pharmaceutical manufacturing, and chemical industries, where the cleanliness of the vacuum chamber is vital.

2. Pump Exhaust Filters

Exhaust filters are essential for removing contaminants from the exhaust of the vacuum pump. They are especially important in applications where the pump’s exhaust may contain harmful substances, such as oil mist or toxic gases.

- Function: Capture contaminants such as oil mist and other particles from the exhaust before they are released into the atmosphere.

- Common Types: The most common are oil mist eliminators.

Pump exhaust filters are vital for ensuring compliance with environmental regulations, especially in applications where vacuum pumps handle hazardous materials or in cleanroom settings.

3. Oil Mist Eliminators

Oil mist eliminators are a type of exhaust filter specifically designed to remove oil aerosols from the exhaust of oil-sealed rotary vane pumps. They prevent oil mist from being released into the environment, which can be both harmful and messy.

- Function: Remove oil particles to prevent contamination of the working environment.

- Importance: They help reduce environmental pollution and keep the workspace clean.

These filters are particularly important in industries where maintaining a clean working environment is critical, such as electronics and pharmaceuticals.

4. Activated Carbon Filters

Activated carbon filters are used to remove organic vapors and gases from the vacuum system. They are an effective solution when handling vapors that could contaminate the vacuum pump or the overall process.

- Application: Common in chemical processes and laboratories where the exhaust gases may contain harmful organic vapors.

- Advantages: Activated carbon is highly effective in adsorbing a wide range of chemical contaminants.

5. Coalescing Filters

Coalescing filters are specifically designed to separate liquids and aerosols from gases. These filters use coalescence to capture mist and condense it into larger droplets, which are then drained away.

- Function: Separate oil and water aerosols from the exhaust.

- Usage: Frequently used in applications involving oil-sealed vacuum pumps.

6. Particulate Filters

Particulate filters remove fine dust and particulates from the vacuum line. These filters are particularly beneficial in processes that generate a lot of solid particles that could damage or reduce the efficiency of the pump.

- Common Materials: Filters often use fibrous or mesh materials to trap particulates.

- Importance: They play a key role in protecting downstream equipment and ensuring the vacuum pump works at optimum efficiency.

7. Vacuum Pump Inlet Traps

Inlet traps are often used in systems where the gases being pumped contain large amounts of contaminants that can rapidly degrade the vacuum pump oil or its mechanical components.

- Materials Used: Inlet traps may use stainless steel mesh or activated alumina to trap particles or adsorb gases.

- Function: Prevent contaminants from reaching the vacuum pump and damaging it.

Choosing the Right Vacuum Pump Filter

Choosing the right vacuum pump filter depends on various factors, such as the type of vacuum pump, the application, and the environment in which it will be used.

Key considerations include:

- Type of Contaminants: What type of particles or contaminants are present in the gas being pumped? Dust, oil mist, or chemical vapors may each require a different type of filter.

- Pump Type: Whether you’re using an oil-sealed pump, dry pump, or another type will influence which filters are needed.

- Operating Conditions: Temperature, pressure, and the volume of gases being handled are important factors in filter selection.

| Filter Type | Contaminant Filtered | Application |

|---|---|---|

| Inlet Filter | Dust, Particulates | Dusty environments |

| Exhaust Filter | Oil Mist | Oil-sealed rotary vane pumps |

| Activated Carbon | Organic Vapors | Chemical processes |

| Coalescing Filter | Liquids and Aerosols | Oil-sealed pumps |

Why Proper Filtration Matters

Proper filtration is key to extending the lifespan of a vacuum pump, improving its efficiency, and ensuring the safety of the environment in which it is used. Inadequate filtration can lead to premature pump failure, costly repairs, and even hazardous situations.

A well-maintained vacuum pump filter system results in:

- Extended Pump Life: Minimizes wear and tear on internal components.

- Increased Efficiency: Helps the vacuum pump maintain optimal performance.

- Reduced Contamination: Prevents backstreaming of oil and contaminants into the system.

To learn more about selecting the right filter for your specific vacuum pump, visit vacuumpumppart.com where you can find a wide range of vacuum pump parts and expert advice.

FAQs

1. What are the main types of vacuum pump filters?

There are several types of vacuum pump filters, including inlet filters, exhaust filters, oil mist eliminators, activated carbon filters, and coalescing filters. Each type serves a specific function, such as removing particulates or oil mist.

2. How do I know which filter my vacuum pump needs?

The choice of filter depends on factors like the type of contaminants present, the vacuum pump used, and the specific application. Consult your pump manual or speak to an expert to determine the most suitable filter.

3. Why are oil mist eliminators important?

Oil mist eliminators are crucial for capturing oil aerosols from the exhaust of oil-sealed rotary vane pumps. This helps to keep the work environment clean and minimizes environmental contamination.

4. Can I reuse vacuum pump filters?

Some vacuum pump filters, like metal mesh inlet filters, can be cleaned and reused, while others, like activated carbon filters, need to be replaced regularly.

5. How often should I change my vacuum pump filter?

The frequency of changing a vacuum pump filter depends on usage, the type of contaminants being filtered, and the environment. It is advisable to follow the manufacturer’s guidelines or conduct regular inspections.

6. What is the role of a vacuum pump inlet trap?

A vacuum pump inlet trap prevents contaminants from reaching the pump, thereby protecting it from potential damage and extending its operational life.

Conclusion

Understanding the types of vacuum pump filters and their applications is key to maintaining the efficiency and longevity of your vacuum system. From inlet filters to oil mist eliminators, each filter type serves a specific purpose, contributing to the overall health and functionality of your pump. Ensuring proper filtration can save time, reduce costs, and provide a cleaner, safer work environment.

For more information on vacuum pump parts and to find the right filter for your application, visit vacuumpumppart.com. There, you’ll find a wide range of products, including inlet and exhaust filters, to keep your vacuum systems running efficiently and safely.