How Does a Vacuum Diffusion Pump Work

The vacuum diffusion pump is a crucial component in many high-vacuum systems, widely used across industrial applications and laboratory settings. Understanding how these pumps work is essential to effectively implement them in your systems. A vacuum diffusion pump, often known as an oil diffusion pump, operates using high-speed jets of vapor to achieve extremely low pressures, making them ideal for applications that require high-vacuum conditions. In this article, we will explore in-depth how a vacuum diffusion pump works, its core components, operational principles, and its significance in various applications.

What is a Vacuum Diffusion Pump?

A vacuum diffusion pump is a type of high-capacity pump that utilizes vapor jets to achieve and maintain a vacuum. Unlike mechanical pumps that rely on moving parts like pistons or vanes, diffusion pumps use high-speed vapor streams produced by heating a special diffusion pump oil. The vapor stream captures gas molecules and propels them towards the pump’s exit, creating a lower pressure environment in the system.

Key Components of a Diffusion Pump

To understand how diffusion pumps work, it’s important to know their main parts:

- Boiler or Heater: This part heats the diffusion pump oil to produce a vapor.

- Jet Assembly: The vapor flows through multiple stages of jet assemblies that help achieve high velocity.

- Cooling System: Water or air-cooled coils condense the oil vapor back into liquid form for recycling.

- Vacuum Chamber: The chamber where the pumped molecules are collected.

These components work together to create high-speed vapor jets that remove gas from a vacuum chamber, facilitating the creation of a high or ultra-high vacuum.

Internal Link: For reliable diffusion pump parts, visit our Vacuum Pump Spare Parts Guide.

Applications of Vacuum Diffusion Pumps

Diffusion pumps are widely used for applications that require high-vacuum levels, such as:

- Electron Microscopy: Maintaining ultra-high vacuum for precise imaging.

- Vacuum Coating: Used in manufacturing to coat materials with thin films.

- Mass Spectrometry: For isolating substances in a vacuum.

“Diffusion pumps have remained a favorite for high-vacuum needs due to their reliability and low maintenance costs compared to mechanical pumps.”

How Does a Diffusion Pump Create a Vacuum?

Step 1: Oil Vaporization

The operation of a diffusion pump starts with the heating of silicone oil or another specially designed diffusion pump oil. The oil is vaporized by a heater located at the base of the pump. As the oil heats up, it converts into vapor, which rises through the central jet assembly.

- Temperature Management: Maintaining the right temperature is essential, as overheating or underheating can significantly affect the efficiency of the diffusion pump.

Step 2: Jet Formation and Vapor Flow

The oil vapor moves through the jet assembly, consisting of multiple nozzles arranged in a series. These nozzles force the vapor into high-speed jets that travel downwards, creating a powerful entrainment effect.

- High-Velocity Jets: The downward flow of vapor forms a series of jets that capture gas molecules in the vacuum chamber.

- Entrainment Process: The gas molecules in the vacuum chamber are entrained by the vapor, pulled towards the pump throat where they are eventually expelled.

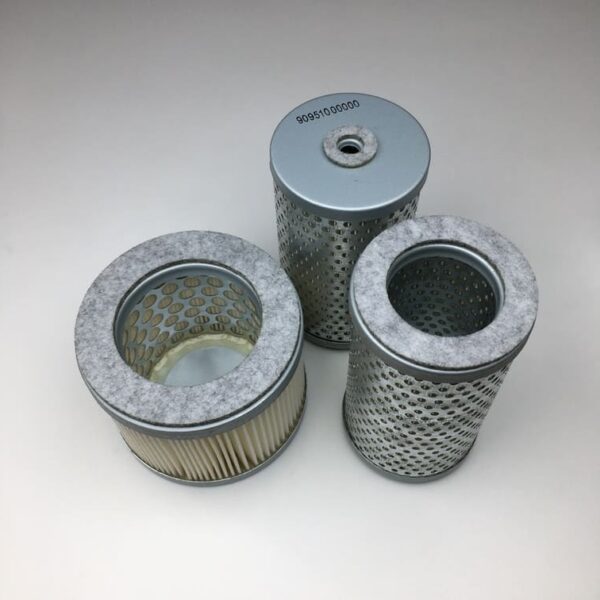

Internal Link: Looking for quality air filters to improve your vacuum system? Check out our Becker Air Filters.

Step 3: Condensation and Recirculation

After the oil vapor has entrained the gas molecules, it reaches the outer cooling system. Here, the cooling coils condense the vapor back into liquid form, which flows back to the reservoir for reuse. This closed-loop system ensures that the pump can operate continuously without needing constant oil replenishment.

- Cooling System: A properly functioning cooling system is crucial for effective condensation of the oil vapor, which helps maintain efficiency.

Key Factors in Achieving Effective Pumping Speed

The pumping speed of a vacuum diffusion pump is influenced by several factors:

- Jet Velocity: The velocity of the oil vapor jets, which depends largely on the temperature of the boiler.

- System Pressure: The diffusion pump operates most effectively at lower pressures, typically below 0.1 Pascal.

- Oil Quality: The type of diffusion pump oil used can significantly affect pumping efficiency. Oils like silicone-based diffusion oils are often preferred due to their stability and performance.

Types of Diffusion Pump Oils and Their Roles

Diffusion pump oils play a critical role in the efficient functioning of the pump. Here are a few commonly used oils:

| Oil Type | Description |

|---|---|

| Silicone Oil | Highly stable, ideal for high vacuum levels |

| Hydrocarbon Oil | More affordable but less thermally stable |

| Synthetic Oils | Offer a balance of stability and performance |

Using the right oil helps prevent degradation and maintains the vacuum’s integrity over extended periods.

Internal Link: For premium-quality carbon vanes, visit our Carbon Vanes Collection.

Advantages and Disadvantages of Diffusion Pumps

Advantages

- High Pumping Speed: Diffusion pumps provide an exceptionally high pumping speed and can maintain a vacuum level as low as 10⁻¹⁰ Torr.

- No Moving Parts: Since they do not have moving parts, diffusion pumps are low-maintenance and are less prone to mechanical failures compared to other pump types.

- Cost-Effective for High Vacuum: They are more economical than turbomolecular pumps for similar vacuum levels.

Disadvantages

- Backstreaming: One of the main challenges with diffusion pumps is oil backstreaming, where vapor can contaminate the vacuum chamber. To avoid this, cold traps or baffles are often used.

- Oil Degradation: The oil used in diffusion pumps may degrade over time, especially if exposed to contaminants.

Best Practices for Operating a Diffusion Pump

1. Proper Warm-Up Time

Always allow the diffusion pump sufficient time to reach operating temperature before exposing it to a vacuum chamber. This ensures that the oil is adequately vaporized to provide effective pumping.

2. Minimize Contamination

Avoid introducing contaminants into the vacuum system that can degrade the diffusion pump oil. Using oil filters and ensuring all components are clean can help extend the pump’s lifespan.

3. Regular Maintenance

- Change Diffusion Oil: Regularly changing the diffusion pump oil is essential. The frequency depends on the workload and type of oil, but as a rule, it should be done every 6-12 months.

- Check Cooling System: Inspect the cooling system to ensure it is functioning correctly, as proper condensation is key for pump performance.

FAQs

1. How do I prevent backstreaming in a diffusion pump?

Using cold traps or baffles between the pump and the vacuum chamber can help prevent oil backstreaming and maintain a clean vacuum environment.

2. What is the difference between a diffusion pump and a turbomolecular pump?

While both are used to achieve high vacuums, turbomolecular pumps use rapidly rotating blades to move gas, whereas diffusion pumps use vapor jets to entrain gas molecules.

3. What type of oil should I use in my diffusion pump?

Silicone-based oils are generally recommended for their stability and performance, especially in high-temperature and high-vacuum conditions.

4. Can diffusion pumps be used in all vacuum systems?

No, diffusion pumps are best suited for high and ultra-high vacuum systems and should not be used in applications requiring cleanliness unless proper measures, like cold traps, are taken.

5. How long do diffusion pumps last?

With proper maintenance, a diffusion pump can last for many years. Regular oil changes and avoiding contamination are key to longevity.

Conclusion

The vacuum diffusion pump is an indispensable tool for achieving high and ultra-high vacuum levels, with applications spanning across scientific research and industrial manufacturing. By understanding the operational principles, such as vapor jet entrainment, and maintaining the pump through regular oil changes and cooling system checks, you can optimize its performance and ensure longevity. Diffusion pumps provide a reliable and cost-effective solution for vacuum systems, and knowing how they work can help you make informed decisions about their implementation.

For high-quality vacuum parts and accessories, including diffusion pump oils and carbon vanes, visit vacuumpumppart.com.