Handling vacuum pumps requires an understanding of the safety risks involved, especially when dealing with potentially hazardous materials like flammable fumes. One question that is often raised is, Could flammable fumes pulled through a vacuum pump ignite? This is a critical topic, particularly for industries relying on vacuum pumps in various settings, including chemical processing, industrial maintenance, and laboratory work.

In this comprehensive guide, we will explore the conditions under which flammable fumes might ignite when processed through a vacuum pump, as well as best practices for ensuring safe operation. Additionally, we’ll dive into the mechanics of vacuum pumps, safety considerations, and how to minimize the risks of ignition.

What Are Flammable Fumes?

Flammable fumes are gaseous substances that can catch fire when exposed to an ignition source, such as a spark or excessive heat. These fumes are often byproducts of volatile liquids, solvents, or combustible chemicals used in industrial processes. Common examples include:

- Petroleum-based solvents like toluene and xylene.

- Alcohols such as methanol and ethanol.

- Gases including butane, propane, and methane.

Flammable fumes can easily form explosive mixtures when mixed with air, making it crucial to manage their handling carefully. Vacuum pumps, which pull gases and vapors through their chambers, can become a point of concern when dealing with these kinds of materials.

How Do Vacuum Pumps Work?

A vacuum pump is a mechanical device designed to remove air and gases from an enclosed space, creating a vacuum. Vacuum pumps are used for numerous applications, such as:

- Chemical processing: Removing volatile gases during reactions.

- Medical and lab use: Managing low-pressure environments for research purposes.

- Industrial systems: Controlling pressure in manufacturing processes.

There are several types of vacuum pumps, such as rotary vane pumps, diaphragm pumps, and turbomolecular pumps. Each type has its specific applications and limitations, but when it comes to dealing with flammable fumes, certain inherent risks apply.

The Risk of Ignition in Vacuum Pumps

Vacuum pumps can pose a risk when processing flammable fumes due to the combination of heat, mechanical friction, and the presence of vapors. The potential for ignition arises from several conditions:

1. Heat Generated by the Pump

Most vacuum pumps generate heat due to the friction of moving parts. In the presence of flammable fumes, this heat could potentially reach a temperature that causes auto-ignition. The auto-ignition temperature varies for different chemicals, and if the pump’s internal temperature exceeds this limit, there is a risk that fumes could ignite.

- Key Consideration: Regular maintenance is required to ensure the pump does not overheat. Utilizing temperature monitoring can prevent the occurrence of overheating, thereby reducing the risk.

2. Spark Generation by Mechanical Components

Vacuum pumps rely on moving mechanical components, which can sometimes produce sparks, especially in older or poorly maintained equipment. These sparks can act as an ignition source when flammable fumes are present.

- Preventive Measure: Using explosion-proof pumps or pumps rated for use in hazardous environments can greatly reduce the risk of ignition from sparks.

3. Presence of Oxygen and Flammable Fumes

For combustion to occur, oxygen, heat, and a flammable substance must all be present. In the case of vacuum pumps, fumes pulled through the system may still be mixed with atmospheric oxygen. This creates a situation where an ignition source (e.g., heat or spark) could ignite the fumes.

- Solution: Using inert gases such as nitrogen to purge the system can displace oxygen, thereby minimizing the risk of ignition.

Best Practices for Handling Flammable Fumes in Vacuum Pumps

To safely handle vacuum pumps when flammable fumes are present, several best practices must be followed:

1. Use Appropriate Pump Types

Selecting the right type of vacuum pump is crucial when dealing with flammable substances. Some vacuum pumps are designed specifically to handle volatile gases and fumes. For instance:

- Diaphragm pumps: These pumps are known for their non-lubricated operation, which reduces the risk of ignition.

- Rotary vane pumps with inert barrier gases: These pumps prevent the buildup of oxygen, reducing the risk of a flammable environment.

2. Monitor Temperature Closely

To minimize risks, it’s important to constantly monitor the temperature of your vacuum pump:

- Temperature Sensors: Install temperature sensors to monitor the pump continuously. Set limits that will trigger alarms if temperatures rise above safe levels.

- Cooling Systems: Use an appropriate cooling system to dissipate heat from the vacuum pump and prevent overheating.

3. Prevent Static Electricity Build-up

Static electricity can lead to an explosion in the presence of flammable fumes. Ensuring that the pump and any associated piping are properly grounded will significantly reduce this risk.

- Anti-static Devices: Using anti-static belts or mats can help prevent static buildup.

- Grounding: Always ensure proper grounding connections between different pump components and equipment.

Safety Mechanisms for Vacuum Pumps

There are various safety mechanisms designed to ensure that vacuum pumps operate safely when processing flammable fumes. These mechanisms serve to mitigate ignition risks and ensure the pump’s safe operation under challenging conditions.

1. Gas Ballast Valves

A gas ballast valve helps prevent condensation of vapors within the pump by admitting atmospheric air or inert gas into the pump. This prevents flammable gases from reaching concentrations that could pose a combustion risk.

- Gas Ballast Example: A gas ballast mechanism is commonly used in rotary vane pumps to prevent the condensation of water vapor and reduce the risk of contamination or ignition.

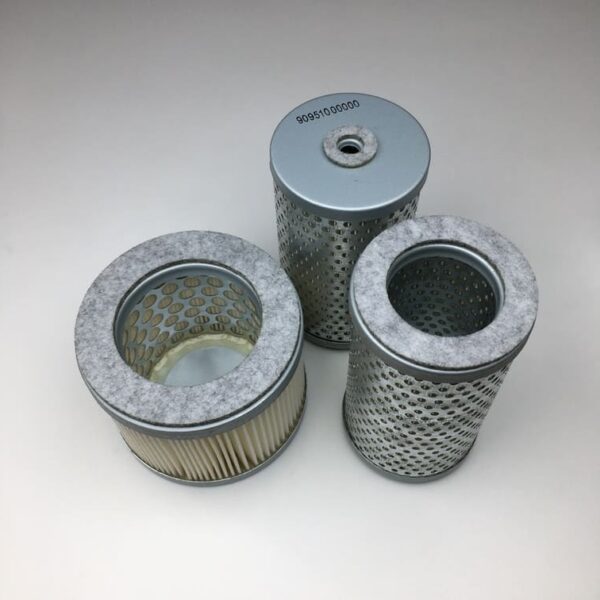

Find out about Becker Air Filters, which keep the system clean and prevent flammable buildup.

2. Flame Arresters

Flame arresters are installed in the exhaust path of vacuum pumps to stop the propagation of flames if ignition does occur. This is an essential safety feature in environments where flammable fumes are common.

3. Inert Gas Purging

In environments where the presence of oxygen is a concern, inert gas purging can be used to replace air with an inert gas like nitrogen. This effectively reduces the risk of combustion since inert gases do not support combustion.

- Inert Gas Purge Systems: For processes involving high flammability risk, an inert gas purge system can be integrated with the pump to minimize any potential hazards.

How to Dispose of Flammable Fumes Safely

Disposing of flammable fumes that are pulled through a vacuum pump is a critical consideration. Improper disposal could lead to environmental damage or even explosions.

Best Practices for Disposal

- Activated Carbon Filters: Passing the fumes through an activated carbon filter can absorb many volatile compounds before they are vented to the atmosphere.

- Chemical Scrubbers: Scrubbers can be used to neutralize harmful chemicals in fumes.

- Controlled Venting: Venting flammable fumes should only be done through a controlled environment, where there is minimal risk of ignition.

Common Applications and Associated Risks

Vacuum pumps are used in diverse applications, and the risks involved may vary depending on the specific application and environment. Below are a few common applications and the risks they entail:

1. Chemical Processing Plants

- Risk: The presence of volatile chemicals means that any vacuum pump used must be explosion-proof and contain anti-spark components.

- Solution: Using diaphragm or scroll pumps can help reduce the risk since these pumps are often safer for handling volatile chemicals.

2. Laboratories

- Risk: Laboratories dealing with organic solvents are at risk of ignition if vapors pass through a standard rotary vane pump.

- Solution: Fume hoods and sealed containment systems can significantly reduce the chances of fume ignition.

3. Pharmaceutical Industry

- Risk: Solvent recovery systems often involve pulling solvent fumes through a vacuum pump, which could ignite if proper precautions are not in place.

- Solution: Inert gas purging and flame arresters are often used to mitigate these risks.

FAQs

1. Could a vacuum pump ignite flammable fumes under normal operating conditions?

Vacuum pumps can ignite flammable fumes if conditions like excessive heat, presence of sparks, or poor ventilation exist. Therefore, using pumps designed for hazardous environments is crucial.

2. How can I safely handle vacuum pumps that deal with flammable gases?

To handle vacuum pumps safely, ensure you use explosion-proof models, utilize gas ballast valves, and practice inert gas purging when necessary.

3. What are the best safety features to add to a vacuum pump used with flammable substances?

Features like flame arresters, gas ballast valves, and inert gas purging systems are effective in reducing the risk of ignition.

4. Do I need a specific type of vacuum pump for handling flammable fumes?

Yes, it is recommended to use pumps like diaphragm pumps or scroll pumps specifically rated for flammable materials, as they minimize ignition risks.

5. Can vacuum pump oil contribute to the risk of ignition?

Yes, vacuum pump oil itself can be flammable, particularly at high temperatures. Always use appropriate temperature monitoring and high-quality oil to reduce the risk.

Conclusion

Handling flammable fumes through a vacuum pump is a potentially hazardous activity that demands careful consideration of the risks involved. By understanding how vacuum pumps work and recognizing the specific circumstances that can lead to ignition, it’s possible to mitigate these risks effectively. Key safety measures, such as selecting the appropriate pump, temperature monitoring, using gas ballast valves, and adopting inert gas purging, are crucial to ensure safe operation.

When dealing with flammable fumes, make informed choices and ensure that your vacuum pump is properly maintained and fitted with all necessary safety features. If you need additional parts or want to enhance your vacuum pump’s performance, check out our range of Becker vacuum pump spare parts for quality and reliability.