Can I Replace the Engine Driven Vacuum Pump?

When it comes to maintaining a diesel engine, one of the key components that may need attention over time is the engine driven vacuum pump. Many drivers and mechanics face the question: can you replace an engine-driven vacuum pump, and what are the implications of doing so? In this comprehensive guide, we’ll explore the reasons for replacement, how to go about it, and the crucial factors to consider during the process.

Understanding the Engine Driven Vacuum Pump

What is an Engine Driven Vacuum Pump?

An engine driven vacuum pump is a device used primarily in diesel engines to provide vacuum pressure for various essential functions, including power braking and emissions control. Unlike gasoline engines, diesel engines do not naturally generate sufficient vacuum pressure because they operate without a throttle plate restricting air intake. Thus, a dedicated vacuum pump is necessary.

The vacuum pump typically connects to the engine via a belt or gear system. It’s responsible for producing the negative pressure that operates components like the brake booster, which makes braking easier, and various emission control mechanisms that ensure the vehicle complies with environmental standards.

- Brake Booster Functionality: The vacuum pump supplies negative pressure to the brake booster, enabling easier brake operation.

- Emission Systems: It also plays a role in operating the EGR (Exhaust Gas Recirculation) valve, helping to control emissions.

Why Does a Diesel Engine Need a Vacuum Pump?

Diesel engines have unique requirements that differ significantly from gasoline engines. Due to their high compression ratios and lack of a throttle plate, they do not create the vacuum pressure required for auxiliary systems.

- No Throttle Plate: Diesel engines allow air to flow freely, creating no vacuum in the intake manifold.

- High Compression Ratios: The need for a robust vacuum pump arises because of how diesel engines compress air, leading to increased pressure without any natural vacuum generation.

These differences make the vacuum pump a critical component for safe vehicle operation and regulatory compliance in emissions.

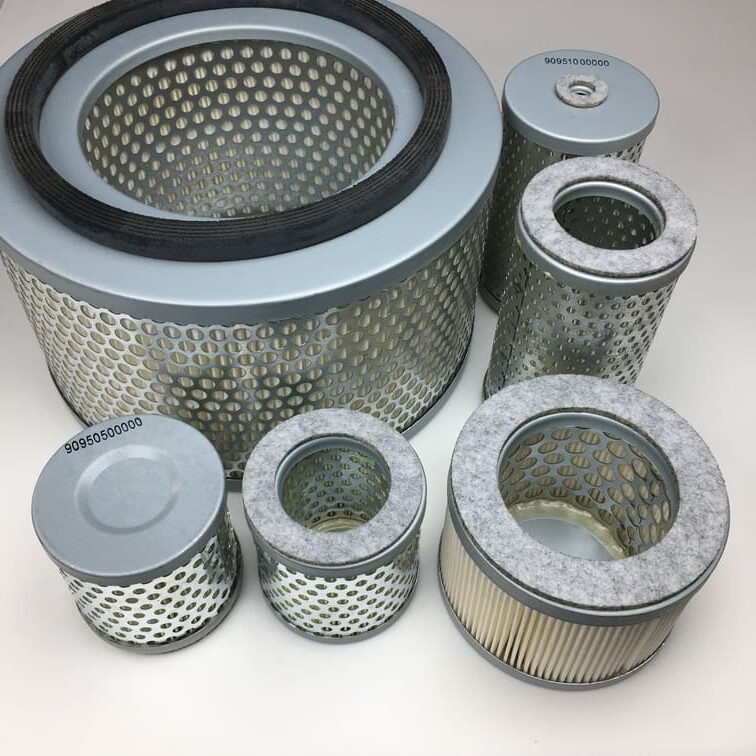

(Becker vacuum pump set of 5 vanes – a key part of vacuum pump maintenance)

(Becker vacuum pump set of 5 vanes – a key part of vacuum pump maintenance)

For more information about vanes and their importance in vacuum pumps, visit our Original Becker Set of 5 Vanes page.

Reasons to Replace an Engine Driven Vacuum Pump

1. Pump Failure Due to Wear and Tear

Like any mechanical component, vacuum pumps are subject to wear and tear over time. The constant spinning of the rotor and vanes causes friction, leading to gradual degradation.

- Vane Wear: The vanes inside a rotary vane pump may wear out, which reduces the pump’s ability to maintain adequate vacuum pressure.

- Seal Deterioration: Seals may degrade, resulting in air leaks that impair the vacuum generation capabilities.

If the brake pedal starts feeling stiff or if braking becomes less effective, it may indicate a problem with the vacuum pump.

2. Oil Contamination

Oil contamination is another common reason for vacuum pump failure. Many engine-driven vacuum pumps use engine oil for lubrication, which means impurities can damage the pump.

- Oil Leaks: Leaks can lead to contamination, compromising the effectiveness of the lubrication.

- Blockages: Contaminated oil can block internal components, causing inefficiencies or complete pump failure.

Regular oil checks and changes are crucial to maintaining the longevity of a vacuum pump.

For high-quality replacement parts, check out our Becker Set of 7 Vanes.

(Becker set of 7 vanes for efficient vacuum pump replacement)

(Becker set of 7 vanes for efficient vacuum pump replacement)

3. Decreased Performance and Safety Concerns

Vacuum pump degradation can lead to decreased overall vehicle performance, especially impacting the brake system. A faulty pump could mean reduced braking power, putting safety at risk.

- Brake Performance: The brake booster relies heavily on the vacuum pump. If the pump fails, the effort needed to press the brake pedal will significantly increase.

- Emission Issues: Faulty pumps may also affect emissions control systems, leading to higher exhaust emissions and potential non-compliance with environmental standards.

Replacing the Engine Driven Vacuum Pump

Can You Replace It Yourself?

Replacing an engine-driven vacuum pump is a task that some DIY enthusiasts may attempt, but it requires a good understanding of engine components and the right tools.

- Mechanical Skills Needed: You need to know how to handle engine belts, pulleys, and other components safely.

- Tools Required: A set of standard automotive tools, including socket wrenches, pliers, and torque wrenches, are typically required.

For those who are not confident in their mechanical skills, it’s advisable to seek professional help to ensure the pump is replaced correctly and all safety protocols are followed.

Step-by-Step Replacement Process

- Disconnect the Battery: Before starting, disconnect the vehicle’s battery to prevent any accidental electrical issues.

- Remove the Belt or Gear Connection: Depending on your vehicle, the vacuum pump may be connected via a serpentine belt or gear. Carefully detach it.

- Remove the Old Pump: Unbolt the vacuum pump and gently remove it from the engine bay. Be mindful of any hoses or electrical connections.

- Install the New Pump: Place the new vacuum pump in position and bolt it securely. Ensure all connections are tight and free of leaks.

- Reconnect the Belt: Reattach the belt or gear, making sure it is properly aligned.

- Test the System: Reconnect the battery and start the engine. Test the brake pedal to ensure that the new pump is functioning as expected.

For reliable replacement parts, consider visiting our Vacuum Pump Spare Parts page.

Choosing Between Mechanical and Electric Pumps

If your vehicle has a mechanical vacuum pump, you might wonder if it’s possible to replace it with an electric one. Electric pumps have some advantages, such as consistent vacuum pressure regardless of engine RPM.

- Mechanical Pumps: Generally reliable but depend on engine speed, meaning they are less effective at low RPMs.

- Electric Pumps: Offer more consistent performance, especially beneficial for vehicles that frequently idle, such as those used in city driving.

The choice between electric and mechanical pumps depends largely on your vehicle type and driving habits. For newer diesel vehicles, electric pumps may offer increased efficiency and lower emissions.

Important Factors to Consider During Replacement

Compatibility

Ensure the replacement pump is compatible with your engine model. Incorrect pumps may not fit or might lead to inefficient vacuum production, impacting other engine systems.

- OEM vs Aftermarket: Consider whether to go for an Original Equipment Manufacturer (OEM) part or an aftermarket alternative. OEM parts ensure compatibility but might be more expensive.

- Mounting Type: Check the mounting type, whether it’s bolted or flange-mounted, to ensure the replacement matches.

Maintenance Post-Replacement

After replacing the vacuum pump, regular maintenance is essential to prolong its lifespan.

- Oil Changes: If your pump uses engine oil, ensure oil changes are done as per the manufacturer’s recommendations to prevent contamination.

- Routine Inspections: Inspect the pump, hoses, and related components for signs of wear or leaks every few months.

The Role of Vacuum Pumps in Emission Control

Modern diesel engines are subject to stringent emission regulations. The vacuum pump helps control various systems that contribute to reduced emissions.

Supporting the EGR System

The Exhaust Gas Recirculation (EGR) system plays a key role in reducing nitrogen oxides (NOx). The vacuum pump provides the necessary pressure to operate the EGR valve effectively, which recirculates a portion of the exhaust gases back into the combustion chamber.

- Environmental Compliance: Properly functioning vacuum pumps are crucial for meeting Euro 6 or similar emission standards.

- Fuel Efficiency: Efficient operation of emission controls can also lead to improved fuel efficiency, benefiting both the environment and your wallet.

Frequently Asked Questions

1. How do I know if my vacuum pump needs to be replaced?

Common signs include a stiff brake pedal, longer stopping distances, and unusual noises from the engine bay. Reduced braking performance is a significant indicator.

2. Can I upgrade from a mechanical vacuum pump to an electric one?

Yes, but it requires additional modifications, including electrical wiring. Consult with a professional to see if your vehicle is suitable for this upgrade.

3. How often should I replace my vacuum pump?

The lifespan of a vacuum pump varies depending on the vehicle’s use and maintenance. Typically, they should last 100,000 to 150,000 miles if well-maintained.

4. What happens if I ignore a faulty vacuum pump?

Ignoring a faulty pump can lead to brake failure, increased emissions, and decreased fuel efficiency. It poses a significant safety risk and may lead to costly repairs.

Conclusion

Replacing an engine driven vacuum pump is an important aspect of diesel engine maintenance, ensuring both safety and efficiency. Whether you’re considering replacing the pump yourself or opting for professional help, understanding the role and mechanics of the vacuum pump will aid you in making an informed decision. Regular maintenance, including timely replacements and inspections, will help keep your engine—and by extension, your vehicle—operating smoothly.

If you’re looking for high-quality vacuum pump parts or simply need advice on maintaining your pump, explore our range of Vacuum Pump Spare Parts. Ensuring your vacuum pump is in optimal condition will not only enhance your driving experience but also keep you and your passengers safe.