A/C Vacuum Pump Electric: Everything You Need to Know

The electric A/C vacuum pump is a crucial component in the air conditioning systems of vehicles and HVAC systems for buildings. It is essential for removing air and moisture from the A/C system, ensuring that the refrigerant can function efficiently. This article will provide an in-depth look into how electric A/C vacuum pumps work, their benefits, and what you should consider when using one. If you’ve ever wondered, “What exactly does an electric A/C vacuum pump do?”, this guide will walk you through everything you need to know.

What is an Electric A/C Vacuum Pump?

An electric A/C vacuum pump is a specialized tool used to create a vacuum in an air conditioning system. The vacuum created by the pump effectively removes moisture, air, and other non-condensable gases that can hinder the performance of the refrigeration system. This ensures optimal function by reducing the chances of compressor damage, blockages, and reducing the contaminants present in the system.

How Does an Electric A/C Vacuum Pump Work?

The process of removing air and moisture from an A/C system involves the following steps:

- Creating Negative Pressure: The pump connects to the service valves on an air conditioning system and creates negative pressure.

- Removal of Moisture and Air: As the pressure drops, air and moisture are removed from the system. Moisture is one of the main causes of malfunction in A/C systems because it can freeze and block passages or react with the refrigerant to form acids.

- Safe Operation: Once a vacuum is created, the system is sealed, and refrigerant can be added without the risk of introducing contaminants.

“A vacuum pump is the gateway to an efficient and durable air conditioning system, ensuring all unwanted moisture and gases are purged.”

Why is Moisture Removal Important?

Moisture can cause several issues in an A/C system, including:

- Corrosion of metal components.

- Formation of ice, which can block or damage the system.

- Chemical reactions with refrigerant leading to acid build-up, which can deteriorate seals and hoses.

By creating a deep vacuum, the pump ensures that even small traces of moisture are boiled off and expelled from the system, maintaining the efficiency and safety of the system.

Types of Electric A/C Vacuum Pumps

Electric A/C vacuum pumps come in various types, each suitable for different needs. The most common types are:

1. Single-Stage Electric Vacuum Pumps

A single-stage vacuum pump consists of one piston or vane mechanism that reduces the pressure to create a vacuum. These pumps are usually used for basic evacuation needs and are cost-effective for smaller systems.

- Advantages: Economical and easy to use.

- Disadvantages: Lower vacuum depth, not ideal for systems that need a deeper vacuum.

2. Dual-Stage Electric Vacuum Pumps

A dual-stage vacuum pump has two pistons or vane mechanisms that create a deeper vacuum compared to a single-stage pump.

- Advantages: Greater efficiency, capable of achieving lower pressure for a deeper vacuum.

- Disadvantages: More expensive but highly recommended for applications where complete removal of moisture is crucial.

3. Rotary Vane Pumps

Rotary vane vacuum pumps are commonly used for A/C systems due to their reliable and consistent performance. They consist of vanes mounted in a rotor which, as they spin, create a vacuum by pushing gases through the system.

- Applications: Ideal for HVAC professionals due to their capability of reaching deeper vacuums and handling a variety of gas loads.

For more detailed information on specific pump types and parts, you can visit the Electric A/C Vacuum Pump Parts Section.

Important Features of Electric A/C Vacuum Pumps

When selecting an electric A/C vacuum pump, several features should be considered:

1. Pumping Speed (CFM)

The pumping speed, measured in cubic feet per minute (CFM), determines how fast the pump can remove air from the system. A higher CFM means faster evacuation, which is especially beneficial for larger systems.

- 0.5 to 1.5 CFM: Suitable for small residential A/C units or cars.

- 3 CFM and above: Ideal for commercial systems and larger HVAC setups.

2. Vacuum Depth

The vacuum depth refers to how low the pump can reduce the system’s pressure. Measured in microns, a pump that reaches lower micron levels can ensure that all moisture is removed effectively.

- 500 microns or lower: This is the target range for most HVAC systems to ensure optimal performance.

3. Motor Power and Voltage

The power rating of the motor is essential to ensure it can handle the workload. Typically, these pumps are powered by 110V or 220V, depending on their size and application.

- Portable Units: Usually come with 110V for convenience.

- Heavy-Duty Units: May require 220V, especially for industrial uses.

4. Gas Ballast Valve

Some vacuum pumps feature a gas ballast valve that helps expel water vapor from the oil. This extends the life of the oil and ensures the efficiency of the pump.

Common Applications of Electric A/C Vacuum Pumps

Electric A/C vacuum pumps are widely used in different fields to remove moisture and contaminants from air conditioning and refrigeration systems. Some of their common applications include:

1. Automotive Air Conditioning

In automotive maintenance, electric A/C vacuum pumps are used to evacuate car air conditioning systems before recharging with refrigerant. This process ensures that no moisture or air remains inside, which could compromise the system’s efficiency.

- Average Time Required: A good vacuum pump should take 20-30 minutes to completely evacuate an automotive system.

2. Residential HVAC Systems

In residential heating, ventilation, and air conditioning (HVAC) installations, vacuum pumps ensure that the system runs efficiently and without contaminants.

- Quick Setup: Connecting the vacuum pump to the HVAC system’s service ports creates a vacuum that readies the unit for refrigerant.

3. Refrigeration and Commercial HVAC

Commercial refrigeration systems, such as those used in restaurants or supermarkets, rely heavily on vacuum pumps during installation and maintenance to ensure a clean, moisture-free environment for refrigerants.

For a detailed guide on HVAC pump types and parts, visit the HVAC Section at Vacuum Pump Part Store.

How to Use an Electric A/C Vacuum Pump

Using an electric A/C vacuum pump involves several steps to ensure proper evacuation of the system. Here’s a step-by-step guide to using it effectively:

1. Prepare the System

- Turn Off the Power: Ensure that the A/C system is completely powered off to avoid any accidents.

- Connect the Pump: Attach the pump to the service valve or manifold gauge set using appropriate hoses.

2. Start the Vacuum Pump

- Open Valves: Open the service valves on the gauge set to allow the vacuum pump to start pulling air from the system.

- Run the Pump: Switch on the pump and let it run until the desired vacuum level is achieved. This can take anywhere from 15-30 minutes, depending on the size of the system.

3. Monitor the Vacuum Level

- Check Gauges: Use the gauge set to monitor the micron level of the vacuum. Ideally, aim for 500 microns or less to ensure that all moisture is removed.

4. Close the System

- Turn Off the Pump: Once the target vacuum level is reached, close the valves and turn off the pump.

- Add Refrigerant: The system is now ready for refrigerant charging without the risk of moisture contamination.

Maintenance Tips for Electric A/C Vacuum Pumps

Maintaining your vacuum pump properly ensures it remains effective and extends its service life.

1. Regular Oil Changes

Changing the vacuum pump oil is critical, especially when dealing with systems containing high levels of moisture.

- Frequency: Change the oil after every major use or when it appears cloudy or milky, which indicates contamination.

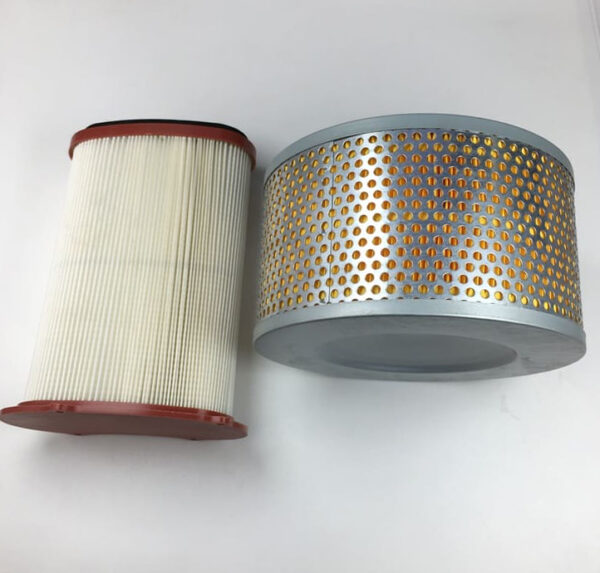

2. Clean Filters and Seals

- Check Filters: Regularly inspect and clean or replace the filters to ensure the pump maintains optimal performance.

- Inspect Seals: Make sure all seals are in good condition to prevent leaks that could hinder the vacuum process.

3. Store Properly

- Clean After Use: After each use, clean the pump and store it in a dry environment to avoid damage from residual moisture or dirt.

FAQs

1. How long does it take to pull a vacuum on an A/C system?

The average time to pull a vacuum on an A/C system depends on the size of the system and the pump’s capacity, but it generally takes 20-30 minutes.

2. What happens if moisture is not removed from an A/C system?

If moisture remains in an A/C system, it can freeze, causing blockages, or react with the refrigerant to form acids, potentially leading to system damage.

3. Can I use a single-stage pump for an automotive A/C system?

Yes, a single-stage pump can work for automotive A/C systems, although a dual-stage pump is recommended for achieving deeper vacuums and ensuring all moisture is removed.

4. How often should I change the oil in my vacuum pump?

The oil in a vacuum pump should be changed whenever it appears cloudy or contaminated, or after each major use, especially when working with moisture-heavy systems.

5. Is a gas ballast valve necessary on a vacuum pump?

A gas ballast valve is highly recommended for pumps that deal with moisture-laden environments, as it helps expel water vapor and keeps the pump oil clean.

Conclusion

An electric A/C vacuum pump plays a vital role in ensuring air conditioning systems function effectively by removing contaminants like moisture and non-condensable gases. Whether used in automotive, residential, or commercial HVAC systems, the proper use of a vacuum pump is key to maintaining efficient and long-lasting performance. Understanding the various features, types, and maintenance tips for these pumps can help you choose the right one and ensure your systems are free from harmful moisture and contaminants.

For more details on vacuum pump parts and maintenance products, you can visit the Vacuum Pump Part Store. With the right knowledge and maintenance routine, your electric A/C vacuum pump will serve you well for years to come.