Perguntas frequentes

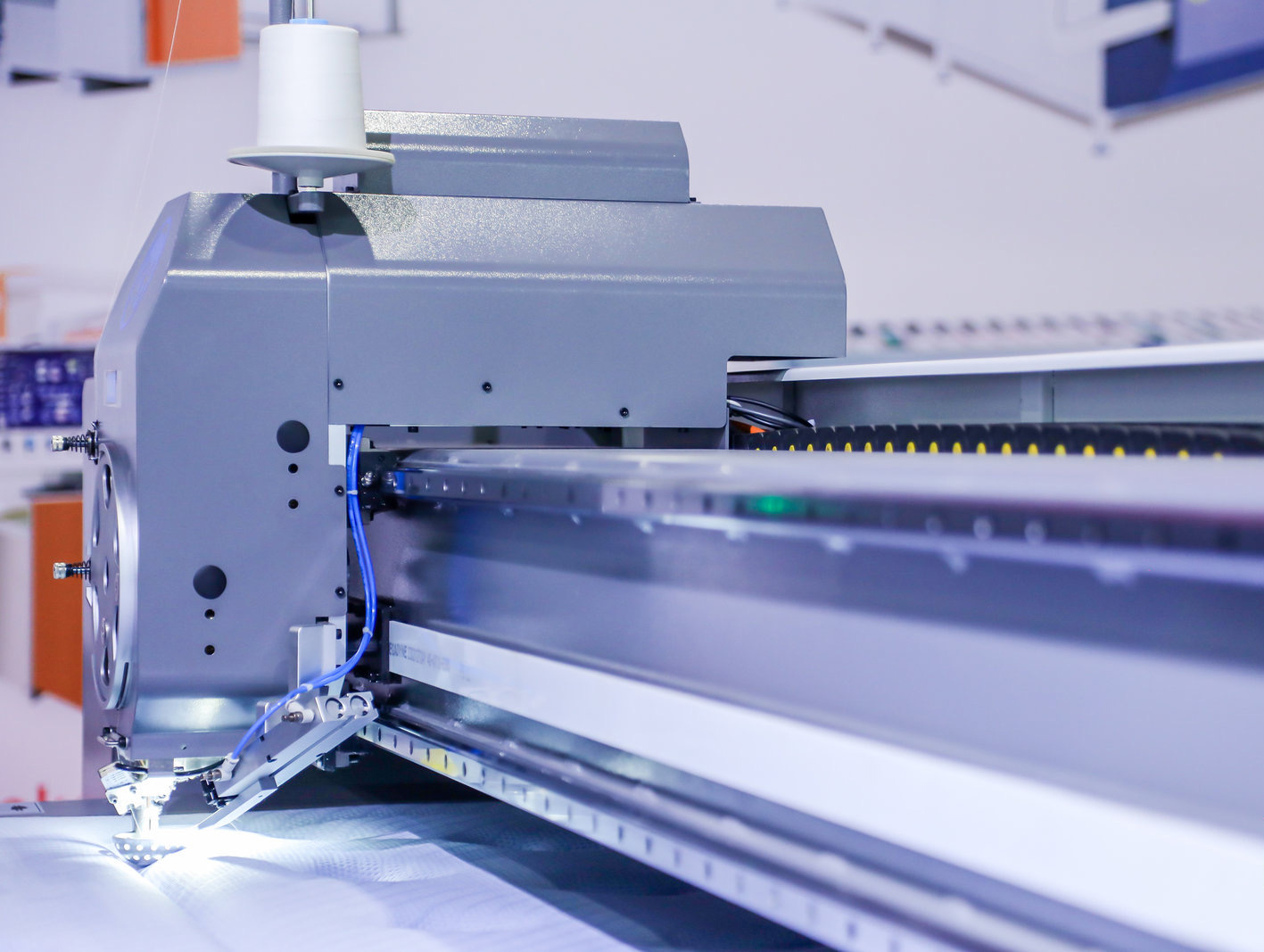

1. P: Quanto tempo demora para meu pedido ser entregue?

UM: Temos orgulho da entrega rápida. Todos os pedidos são processados e enviados em até 3 dias úteis, garantindo tempo de inatividade mínimo para seu equipamento.

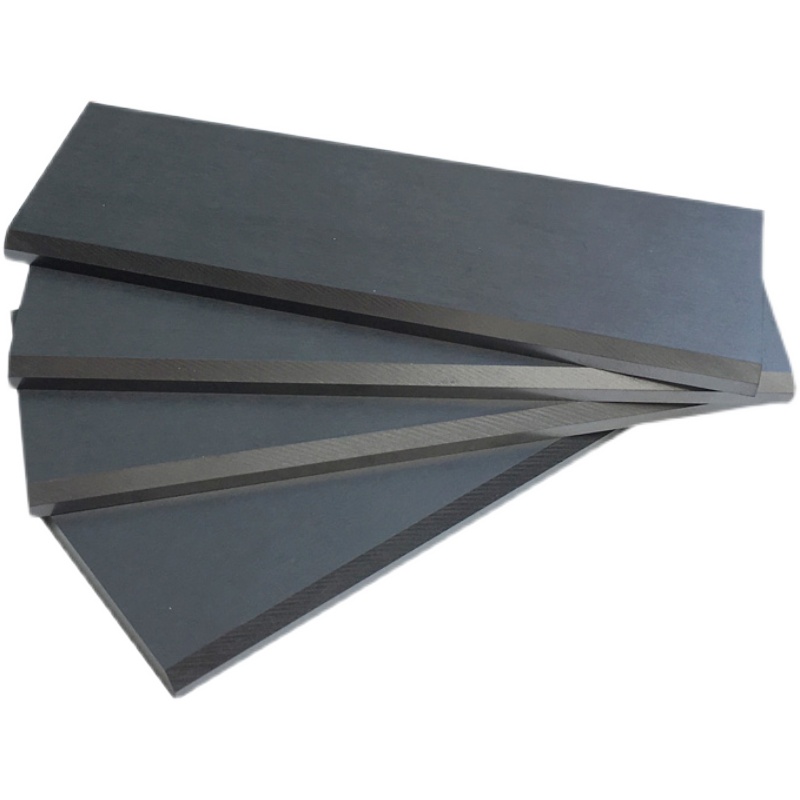

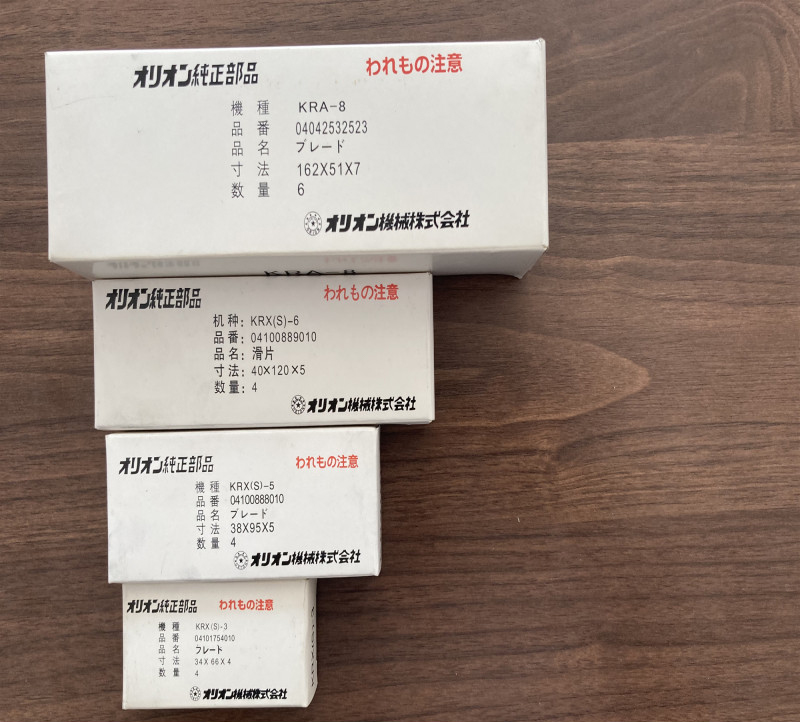

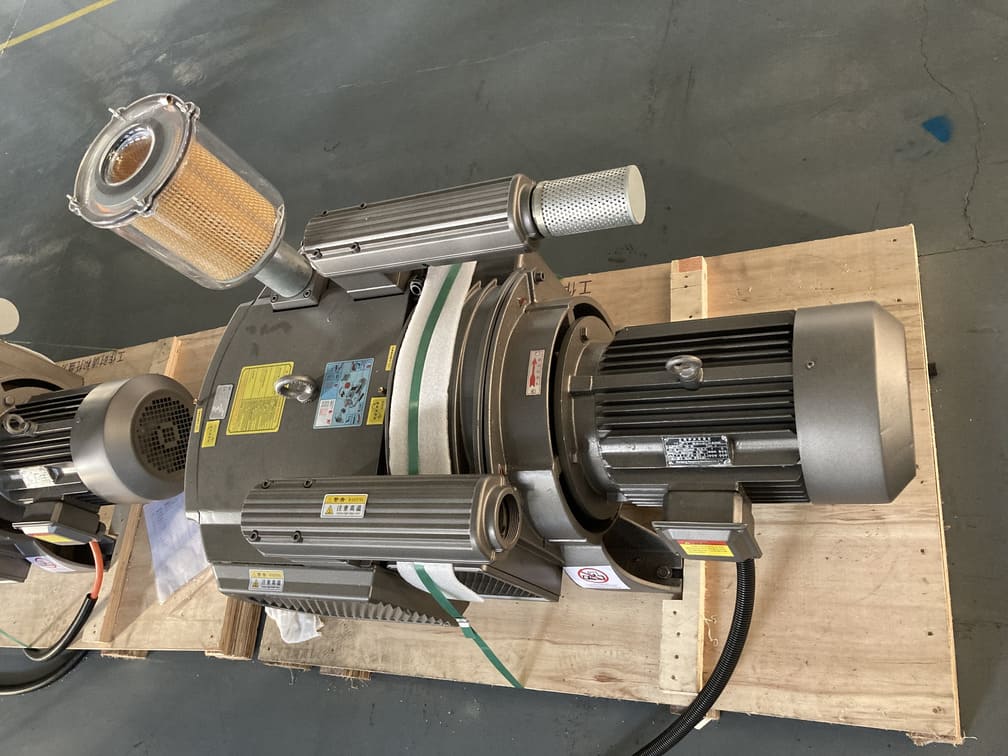

2. P: Que tipo de garantia vocês oferecem para palhetas de carbono?

UM: Sim, todas as nossas palhetas de carbono atendem Padrões de qualidade OEM, garantindo desempenho e longevidade ideais para suas bombas de vácuo.

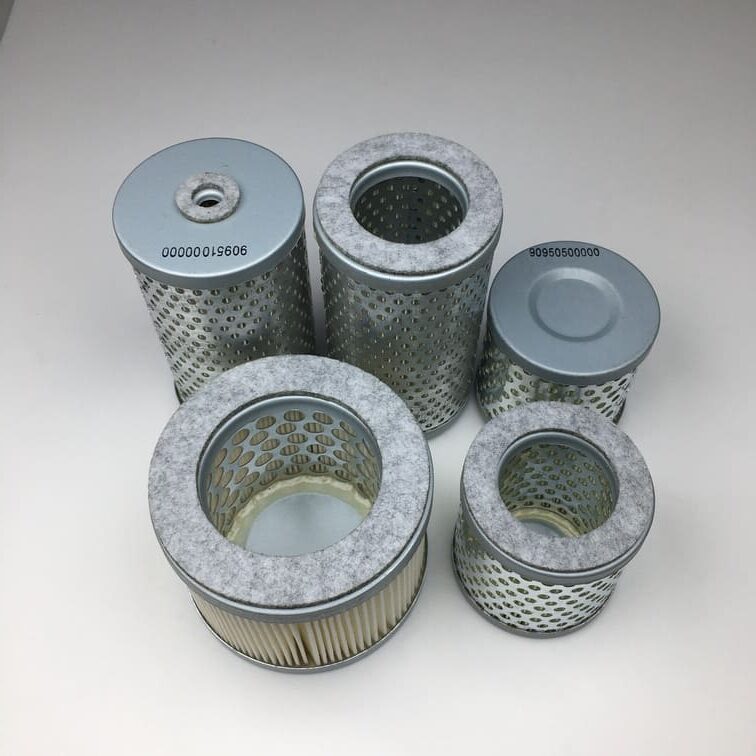

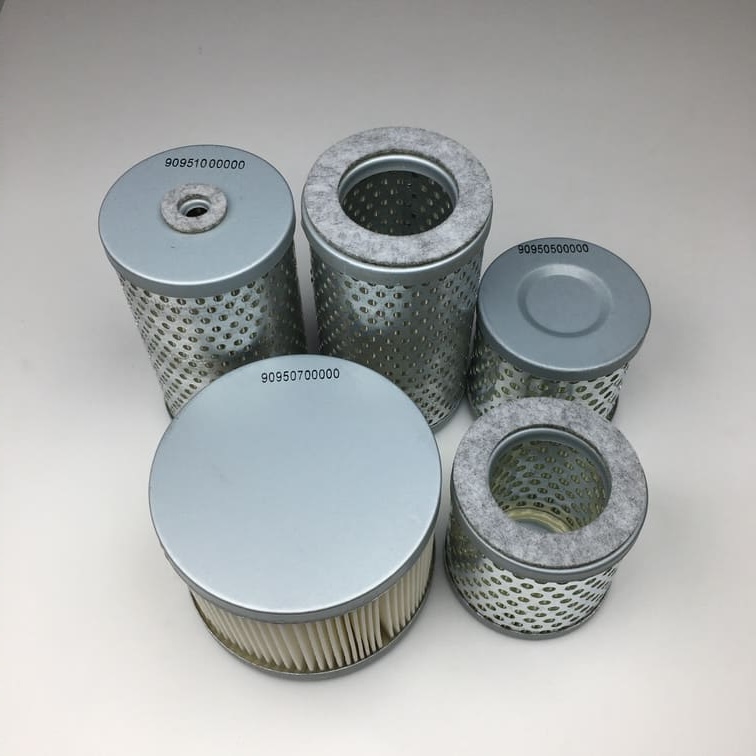

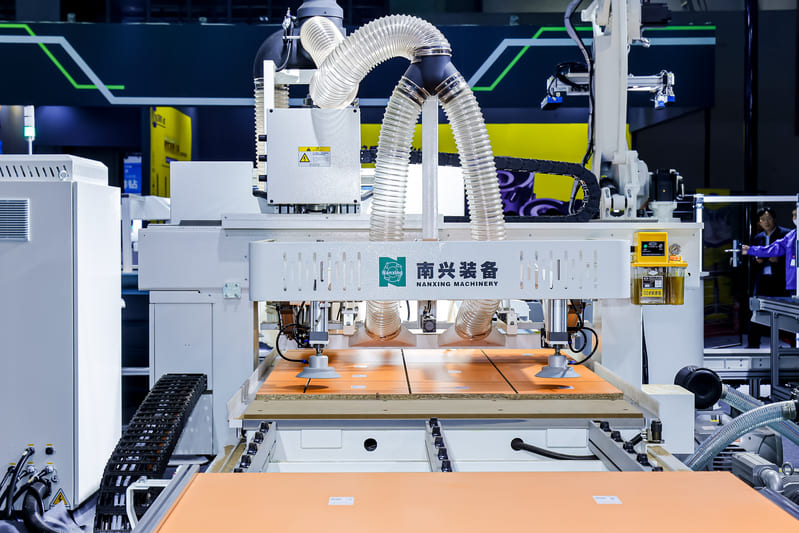

3. P: Com que frequência o filtro deve ser substituído?

UM: Não há um tempo exato de substituição do filtro. Acima de tudo, depende das condições de trabalho.