الأسئلة الشائعة

1.س: كم من الوقت يستغرق تسليم طلبي؟

أ:نحن نفخر بالتسليم السريع. تتم معالجة جميع الطلبات وشحنها خلال 3 أيام عمل، مما يضمن الحد الأدنى من وقت التوقف لمعداتك.

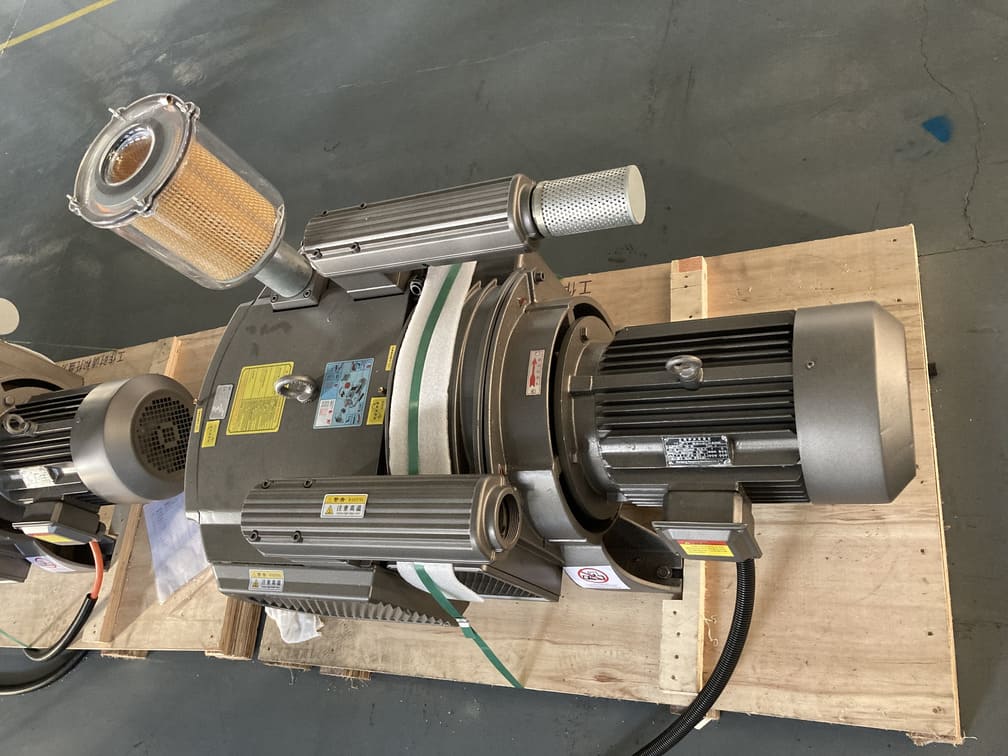

2. س: ما نوع الضمان الذي تقدمه على ريش الكربون؟

أ: نعم، جميع ريش الكربون لدينا تلبي معايير جودة OEM، مما يضمن الأداء الأمثل وطول العمر لمضخات التفريغ الخاصة بك.

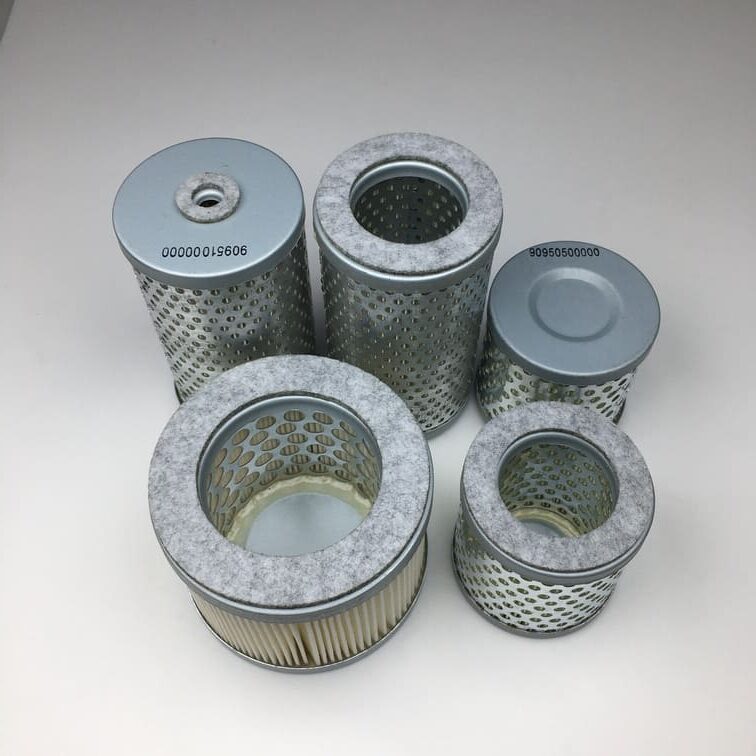

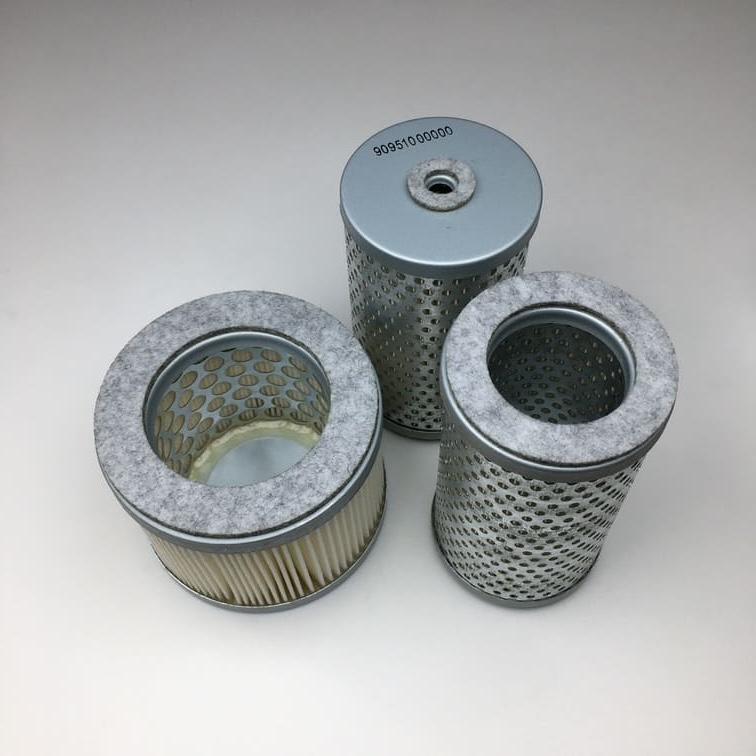

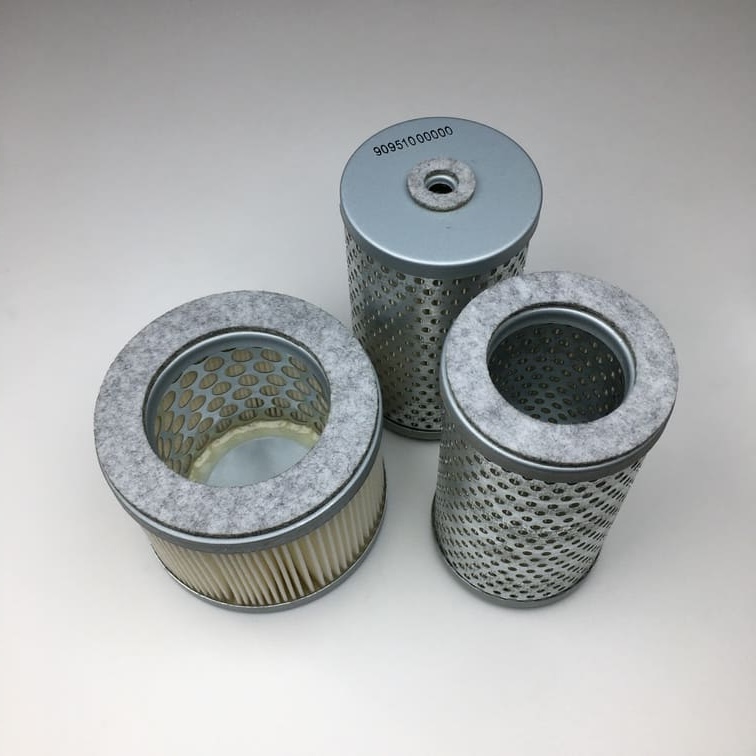

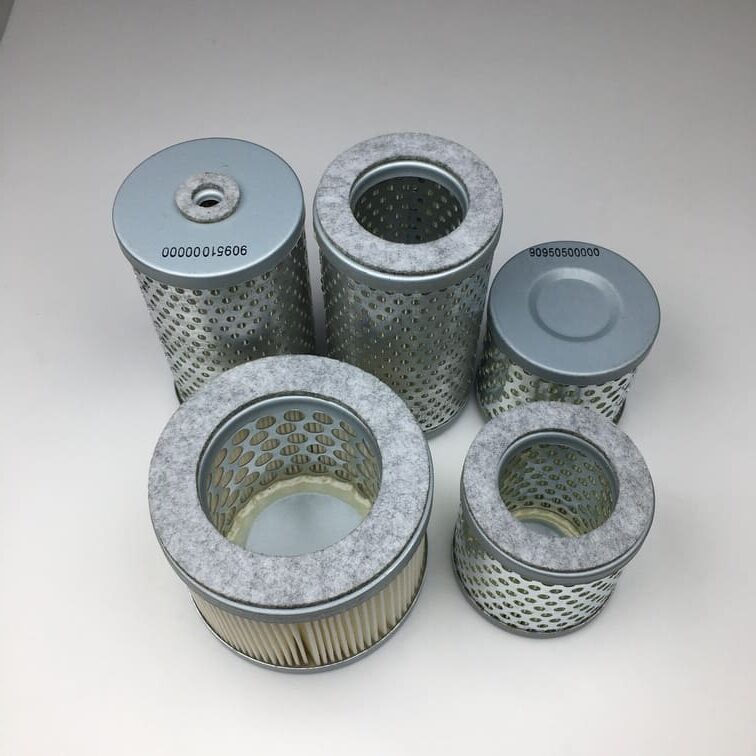

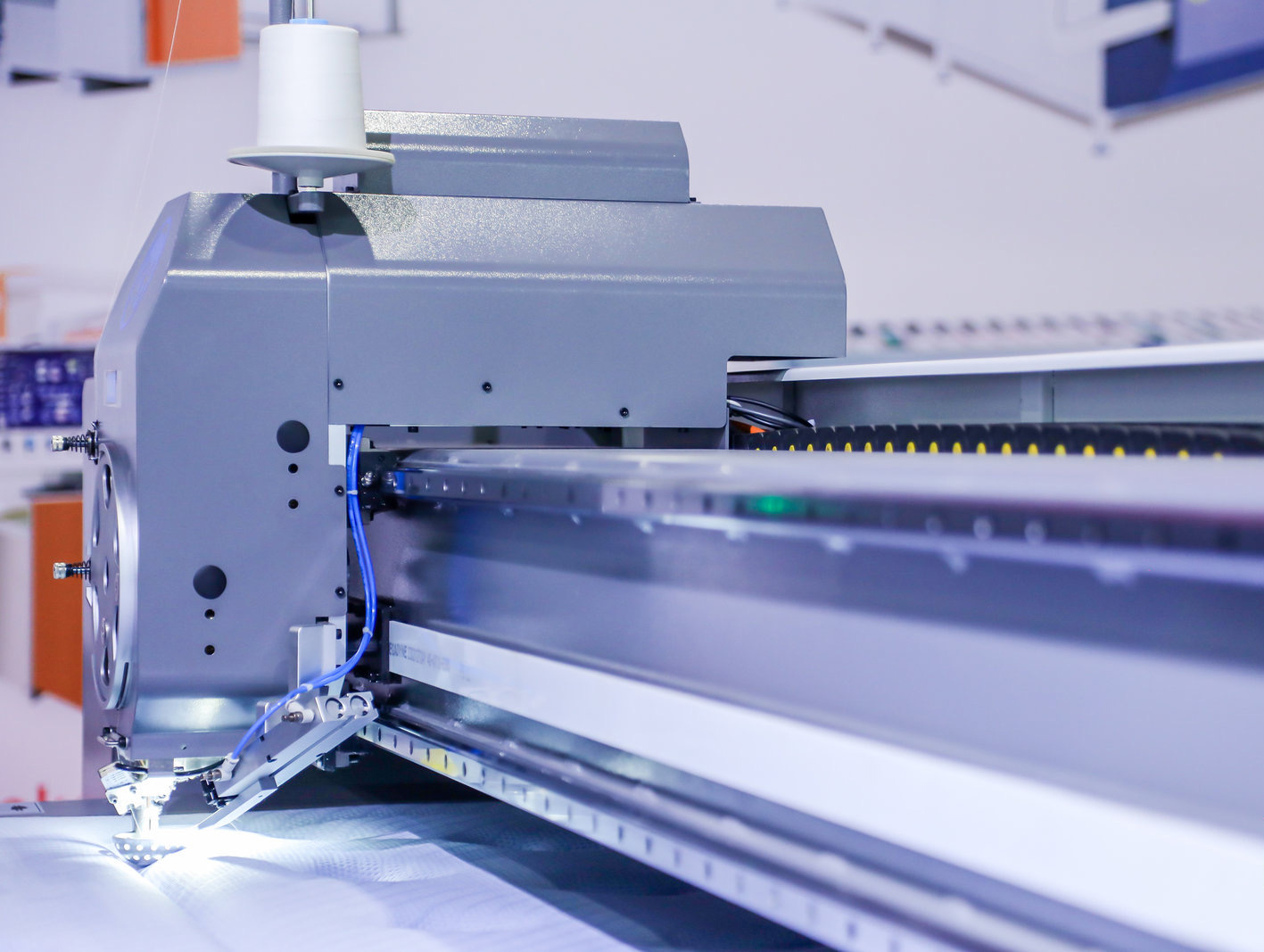

3. س: كم مرة يجب استبدال الفلتر؟

أ:لا يوجد وقت محدد لاستبدال الفلتر. ويعتمد ذلك في المقام الأول على ظروف العمل.